Preparation method of self-adhesive flame retardant sealing tape

A sealing tape, self-adhesive technology, applied in adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve problems such as poor sealing, high price, and insufficient pressure-sensitive adhesiveness of sealing tapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

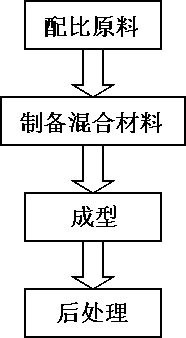

Image

Examples

Embodiment 1

[0018] The specific preparation method is as follows:

[0019] a) Proportioning raw materials, the raw materials selected for the self-adhesive flame retardant sealing tape include: isocyanate, polyether N 220 , polyether N 330 , plasticizer, filler, flame retardant and catalyst; the mass ratio of each component is: isocyanate 36%, polyether N 220 32%, polyether N 330 8%, plasticizer 1%, filler 14%, flame retardant 8%, catalyst 1%; among them, the filler is Shuangfei material and talcum powder, the catalyst is dibutyltin dilaurate and stannous octoate, and the plasticizer is ortho Dioctyl phthalate; the flame retardant uses coated red phosphorus, which is made of organic and inorganic coatings on the surface of red phosphorus. This flame retardant is easily oxidized when heated. Phosphorus oxide, in the environment where water is generated when the polymer is burned, is quickly transformed into metaphosphoric acid, phosphoric acid and various polyphosphoric acids. The resul...

Embodiment 2

[0024] The specific preparation method is as follows:

[0025] a) Proportioning raw materials, the raw materials selected for the self-adhesive flame retardant sealing tape include: isocyanate, polyether N 220 , polyether N 330 , plasticizer, filler, flame retardant and catalyst; the mass ratio of each component is: isocyanate 20%, polyether N 220 40%, polyether N 330 10%, plasticizer 2%, filler 16%, flame retardant 10%, catalyst 2%; among them, the filler is shuangfei material and talcum powder, the catalyst is dibutyltin dilaurate and stannous octoate, and the plasticizer is ortho Dioctyl phthalate; the flame retardant uses coated red phosphorus, which is made of organic and inorganic coatings on the surface of red phosphorus. This flame retardant is easily oxidized when heated. Phosphorus oxide, in the environment where water is generated when the polymer is burned, is quickly transformed into metaphosphoric acid, phosphoric acid and various polyphosphoric acids. The res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com