Crystallization method of 5-aminolevulinic acid phosphate

A technology of aminolevulinic acid phosphate, aminolevulinic acid, applied in chemical instruments and methods, preparation of phosphorus organic compounds, organic compounds, etc., can solve equipment corrosion, unstable chemical properties of 5-aminolevulinic acid, irritating odor and other problems, to achieve the effect of reducing steps, environmental friendliness, and high total yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

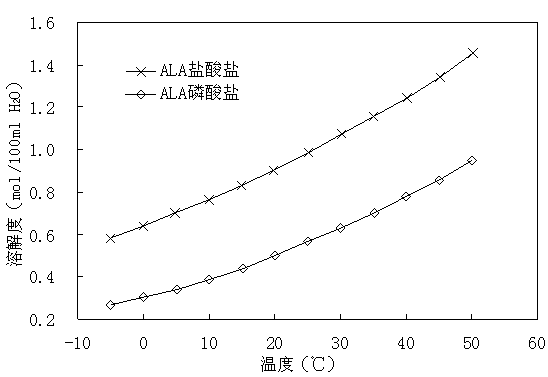

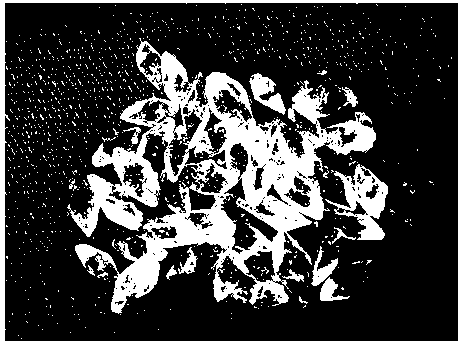

[0043]Dissolve 36 g of 5-aminolevulinic acid hydrochloride crystals obtained by the method described in CN 200910100980.1 with deionized water, dilute to 0.1 M, pass through hydrogen-type strongly acidic ion exchange resin, wash with deionized water, and remove chloride ions , desorbed with alkaline solution, collected 400 ml of the desorbed solution between pH 3 and pH 7, and the concentration of 5-aminolevulinic acid was 0.43 M. Add phosphoric acid to the desorption solution to adjust the pH value of the solution to 2.8; add 4 g of powdered activated carbon, stir at 15 °C for 30 minutes, and filter to obtain a colorless and clear decolorization solution; vacuum concentrate the decolorization solution at 65 °C to 5-aminoacetyl The concentration of propionic acid phosphate reaches 430 g / l; the concentrated solution is gradually cooled under stirring conditions, the stirring speed is 60 rpm, and the cooling rate is controlled at 10 ℃ / h. When crystal nuclei appear in the solution...

Embodiment 2

[0045] 18.6 L of 5-aminolevulinic acid fermentation broth with microfiltration to remove bacterial cells, the concentration of 5-aminolevulinic acid is 25.1 mM, after separation by ion exchange, the desorption solution between pH 3 and pH 7 is washed with 85% phosphoric acid The solution was adjusted to pH 3.2 to obtain a crude aqueous solution of 1850 ml of 5-aminolevulinic acid phosphate, wherein the concentration of 5-aminolevulinic acid phosphate was 46.8 g / L, decolorized with 37 g of powdered activated carbon, and filtered after stirring for 30 min , wash the activated carbon filter cake with a small amount of deionized water, and the obtained filtrate is concentrated in vacuum at 65°C until the concentration of 5-aminolevulinic acid phosphate reaches 570 g / l, and the concentrated solution is gradually cooled under stirring, and the stirring speed is 100 rpm, the cooling rate was controlled at 15°C / h, the stirring was stopped when crystal nuclei appeared in the solution, a...

Embodiment 3

[0047] In Example 1 and Example 2, the remaining mother liquor obtained by suction filtration obtained in the crystallization separation step was mixed, diluted with deionized water until the concentration of 5-aminolevulinic acid was 0.1 M, and the solution volume was 5.49 L, and the solution was removed by ion exchange. The anions of lye were desorbed with lye, and 1050 ml of the desorption solution between pH 3 and pH 7 were collected. The concentration of 5-aminolevulinic acid was 0.42 M. 35.6 ml of 85% phosphoric acid was added to the desorption solution to adjust to pH 3.2, and the desorption Add 40 g of powdered activated carbon to the liquid, stir and decolorize at 15 °C for 50 minutes, and filter to obtain a colorless and clear decolorized liquid. Concentrate the decolorized solution in vacuum at 70°C until the concentration of 5-aminolevulinic acid phosphate reaches 580 g / l, and gradually lower the temperature of the concentrated solution under stirring. The stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com