Process for recycling filter residues of polyaluminium chloride series coagulants

A technology of polyaluminum chloride and coagulant is applied in the field of resource reuse technology of filter residues, which can solve the problem that the filter residues cannot be put into production so as to meet the standards and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

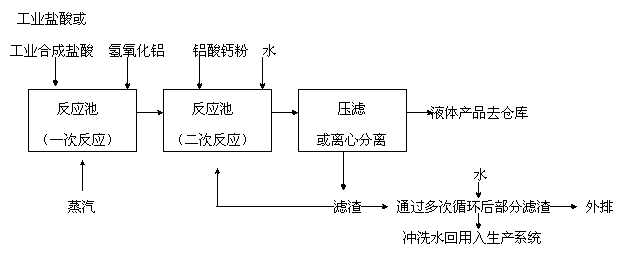

Image

Examples

Embodiment 1

[0035] Embodiment 1, get converted into mass concentration and be 120kg of industrially synthesized hydrochloric acid of 100%, add reaction tank, add aluminum hydroxide 70kg under constant stirring, steam heating, make reaction tank temperature be controlled between 80-110 ℃, reaction 2 hours, then cool to 50-70°C, add 30kg of filter residue and 125kg of calcium aluminate powder under constant stirring, and gradually add 655kg of water, control the flow rate when adding water, so that the solution temperature is controlled within the range of 80-100°C, at this time the total water The amount of water converted from the amount of steam should be deducted, and the liquid residue should be separated after 2 hours of reaction. In this example, pressure filtration is used to obtain 950 kg of polyaluminum chloride for drinking water and 50 kg of filter residue. The finished product meets the national standard of GB 15892-2009, and The obtained filter residue is recycled into the prod...

Embodiment 2

[0036] Example 2, take 160 kg of industrially synthesized hydrochloric acid converted into a mass concentration of 100%, add it to the reaction tank, add 120 kg of aluminum hydroxide under constant stirring, control the temperature of the reaction tank between 80-110 ° C, react for 5 hours, and then cool to 50-70°C, add 50kg of filter residue and 60kg of calcium aluminate powder under continuous stirring, and gradually add 610kg of water. When adding water, control the flow rate so that the solution temperature is controlled within the range of 80-100°C. At this time, the amount of steam should be deducted from the total amount of water. After 3 hours of reaction, carry out liquid slag separation. This example adopts centrifugation to obtain 940kg of polyaluminum chloride for drinking water and 60kg of filter residue. The obtained filter residue is recycled into the production system again.

Embodiment 3

[0037]Example 3, get 135kg of industrial hydrochloric acid converted into a mass concentration of 100%, add to the reaction tank, add 100kg of aluminum hydroxide under constant stirring, control the temperature of the reaction tank between 80-110°C, react for 3 hours, then cool to 50 -70°C, add 40kg of filter residue and 85kg of calcium aluminate powder under continuous stirring, and gradually add 640kg of water. When adding water, control the flow rate so that the solution temperature is controlled within the range of 80-100°C. At this time, the amount of steam should be deducted from the total amount of water to convert After 2.5 hours of reaction, liquid slag separation was carried out. This example adopts pressure filtration to obtain 955kg of industrial polyaluminum chloride as filtrate product, and 45kg of filter residue. The filter residue is recycled into the production system again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com