Diesel vehicle tail gas purifying catalyst and preparation method thereof

An exhaust gas purification and catalyst technology, which is applied in the field of catalyst preparation and vanadium-based SCR catalyst preparation, can solve the problems of high production cost and poor high temperature aging resistance, and achieve the effects of improving performance, enhancing anti-aging performance and good removal rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

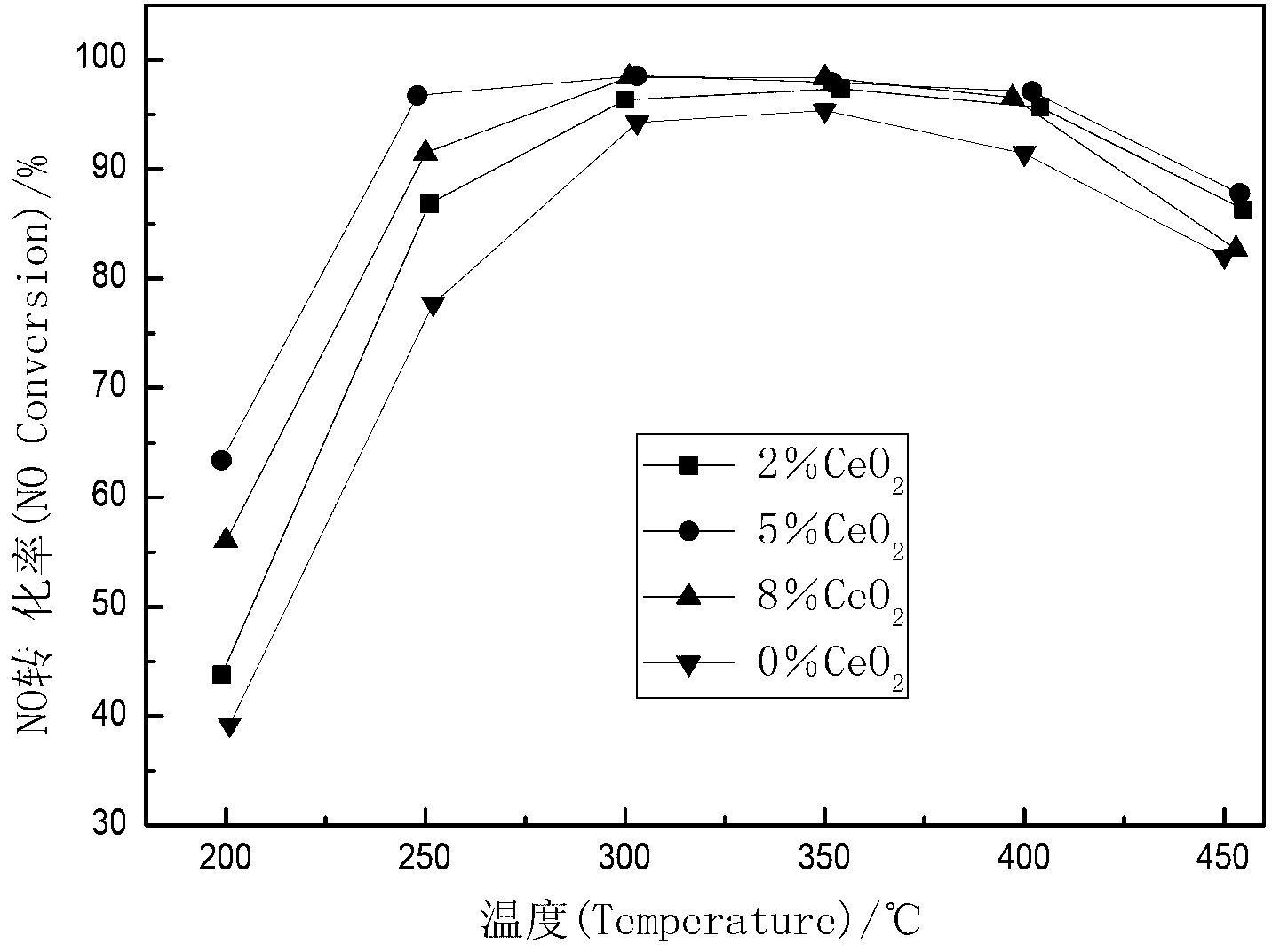

[0026] 3%V 2 o 5 -2%CeO 2 / TiO 2 -SiO 2 -WO 3 Catalyst preparation

[0027] ①Dissolve 13.03g of oxalic acid in 80g of deionized water, add 7.712g of ammonium metavanadate after the oxalic acid is completely dissolved, heat and stir in a water bath at 40-50°C for 1-2 hours, and form a blue solution.

[0028] ②Dissolve 7.305g of cerium nitrate in 17.816g of deionized water to form a 41% cerium nitrate solution, then add it to the solution prepared in step ①, heat and stir in a water bath at 40-50°C for 1-2 hours.

[0029] ③Adjust the volume of the solution in ②to make the total volume 171ml, then add 190g of titanium silicon tungsten powder to the solution obtained in step ②, stir for 1-3 hours to obtain dark blue fine powder.

[0030] ④Put the powder obtained in step ③ into an oven, stay at 60-80°C for 2 hours, and then dry at 120°C for 24 hours.

[0031] ⑤Put the dried powder in step ④ into the muffle furnace and bake at 500-600°C for 3-4 hours to obtain 3% V 2 o 5 -2%C...

Embodiment 2

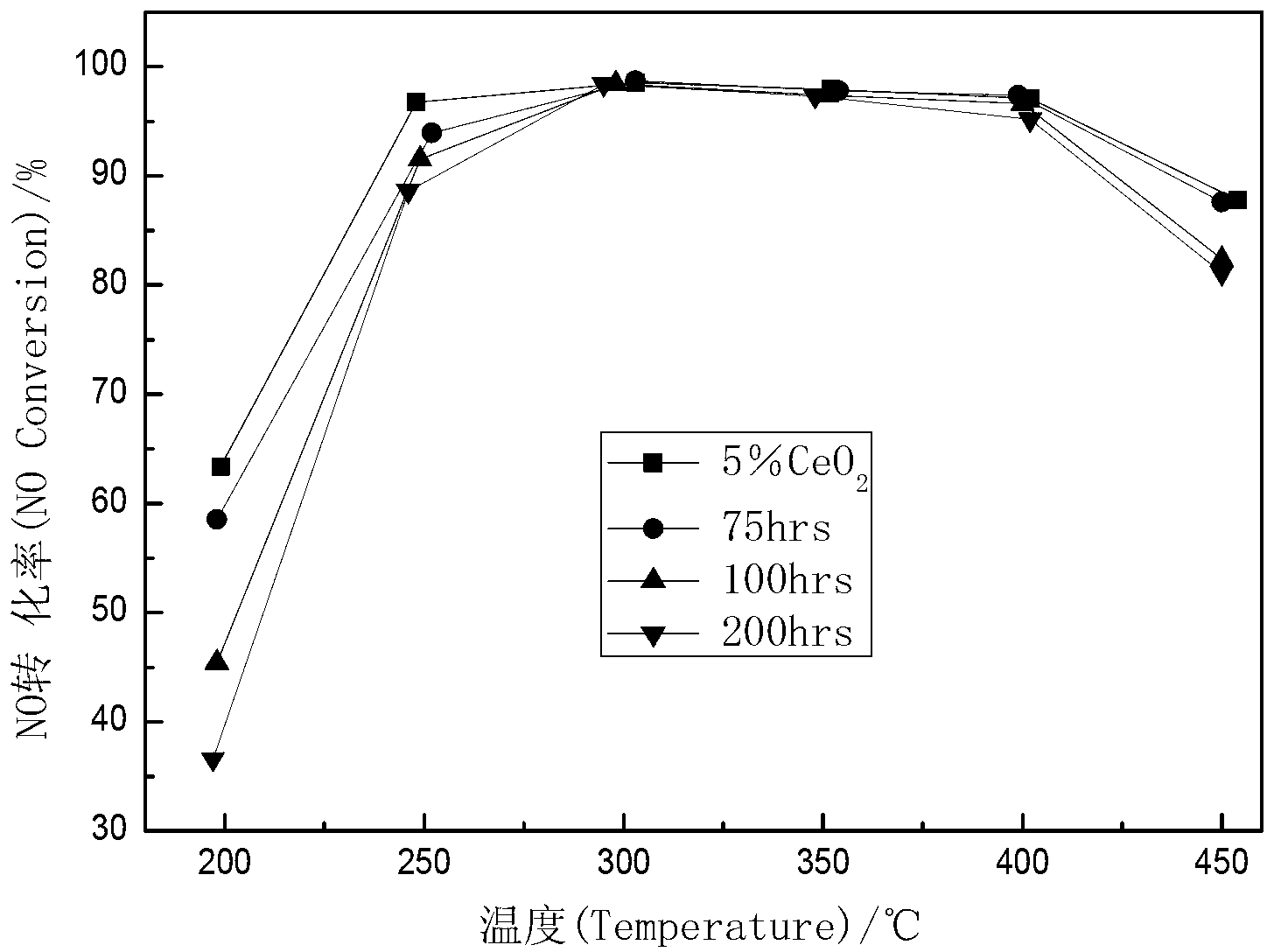

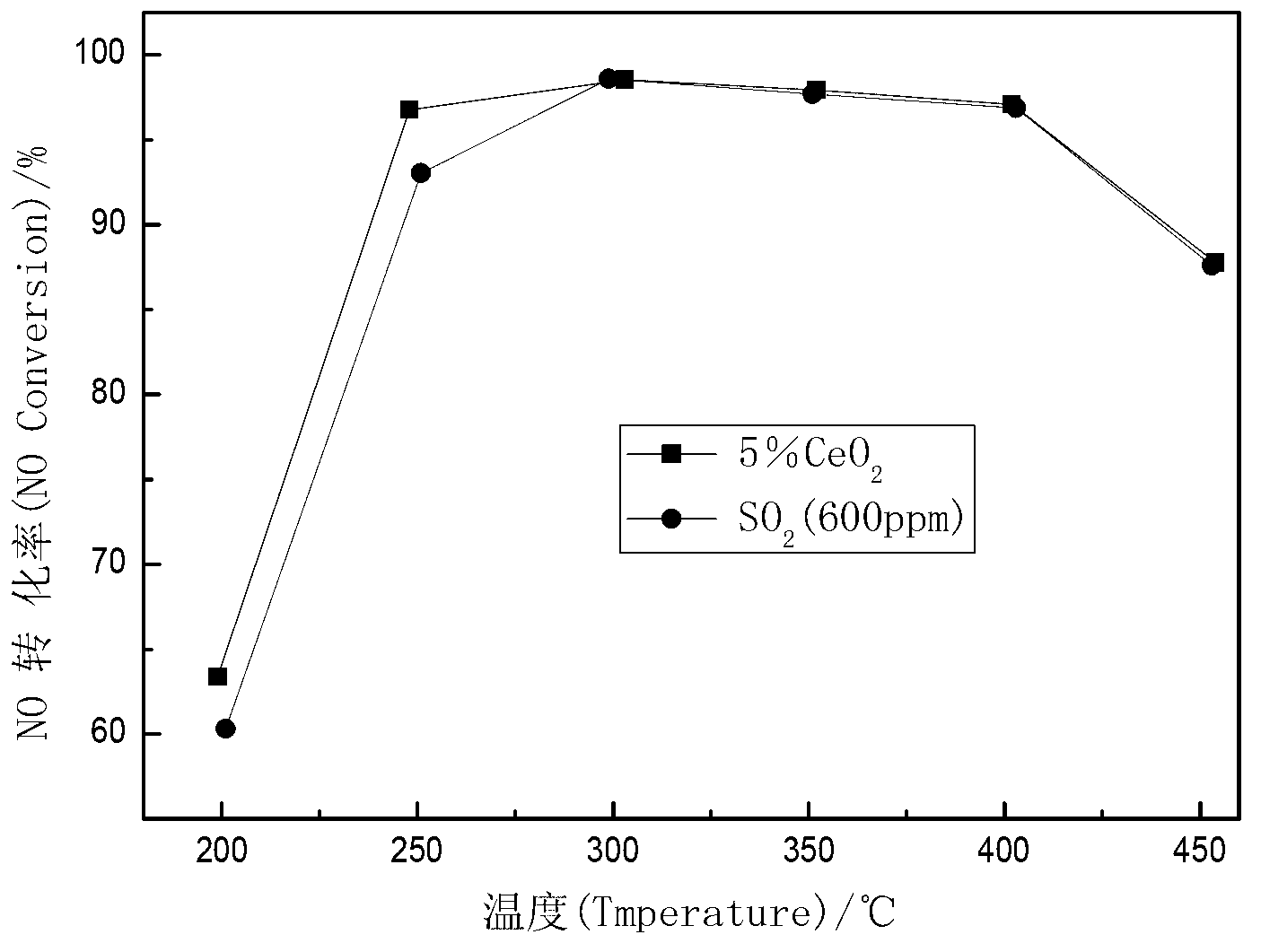

[0034] 3%V 2 o 5 -5%CeO 2 / TiO 2 -SiO 2 -WO 3 Catalyst preparation

[0035] ① Dissolve 13.03g of oxalic acid in 80g of deionized water, add 7.712g of ammonium metavanadate after the oxalic acid is completely dissolved, heat and stir in a water bath at 40-50°C for 1-2 hours, and form a blue solution.

[0036] ②Dissolve 18.263g of cerium nitrate in 44.54g of deionized water to form a 41% cerium nitrate solution, then add it to the solution prepared in step ①, heat and stir in a water bath at 40-50°C for 1-2 hours.

[0037] ③ Adjust the volume of the solution in ② to make the total volume 165.6ml, then add 184g of titanium silicon tungsten powder to the solution obtained in step ②, stir for 1-3 hours to obtain a dark blue fine powder.

[0038] ④Put the powder obtained in step ③ into an oven, stay at 60-80°C for 2 hours, and then dry at 120°C for 24 hours.

[0039] ⑤Put the dried powder in step ④ into the muffle furnace and bake at 500-600°C for 3-4 hours to obtain 3% V 2 ...

Embodiment 3

[0042] 3%V 2 o 5 -8%CeO 2 / TiO 2 -SiO 2 -WO 3 Catalyst preparation

[0043] ① Dissolve 13.03g of oxalic acid in 80g of deionized water, add 7.712g of ammonium metavanadate after the oxalic acid is completely dissolved, heat and stir in a water bath at 40-50°C for 1-2 hours, and form a blue solution.

[0044] ②Dissolve 29.22g of cerium nitrate in 71.264g of deionized water to form a 41% cerium nitrate solution, then add it to the solution prepared in step ①, heat and stir in a water bath at 40-50°C for 1-2 hours.

[0045] ③Adjust the volume of the solution in ②to make the total volume 160.2ml, then add 178g of titanium silicon tungsten powder to the solution obtained in step ②, stir for 1-3 hours to obtain dark blue fine powder.

[0046] ④Put the powder obtained in step ③ into an oven, stay at 60-80°C for 2 hours, and then dry at 120°C for 24 hours.

[0047] ⑤Put the dried powder in step ④ into the muffle furnace and bake at 500-600°C for 3-4 hours to obtain 3% V 2 o 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com