Preparation method of denitration catalyst with nanoscale ordered honeycomb structure

一种脱硝催化剂、蜂窝结构的技术,应用在化学仪器和方法、物理/化学过程催化剂、分离方法等方向,能够解决孔易阻塞、内表面不能充分利用、传质效率不高等问题,达到提高抗硫性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

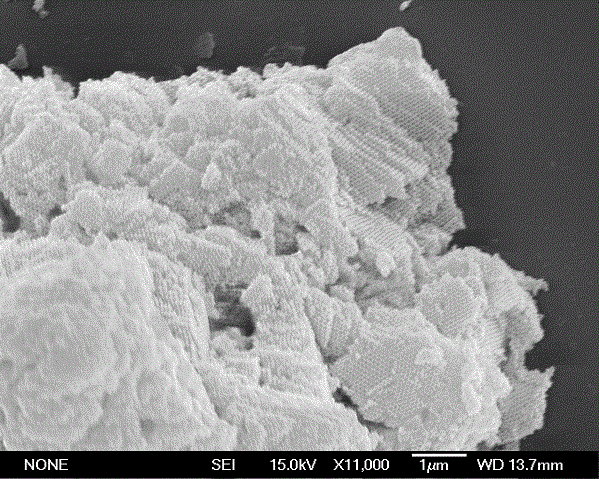

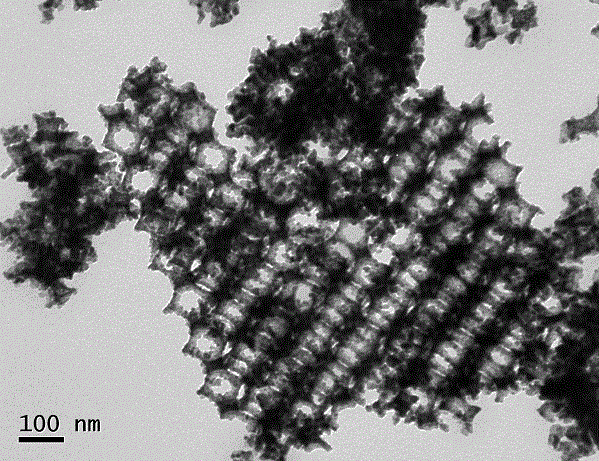

Embodiment 1

[0026] The preparation of catalyst: get styrene monomer and methacrylic acid, sodium bicarbonate and deionized water, after mixing with the mass ratio of 9:0.5:0.24:85, add the ammonium persulfate that massfraction is 0.3% in mixture as Initiator, under nitrogen protection, 85 o C, reacted under stirring conditions for 12h. The reaction products were subjected to evaporative self-assembly after centrifugal washing to prepare polystyrene templates. Cerium oxalate and zirconium silicate with a molar ratio of 8:2 are fully dissolved in a mixed solution of water, citric acid, and ethylene glycol with a mass ratio of 10:5:3, and then adsorbed by a polystyrene template and dried. The product was subsequently treated with 6 o C / min rate heating up to 350 o C, calcined for 2 h, then heated to 750 o C, calcination for 5 h to obtain an ordered honeycomb framework of cerium-zirconium oxide. Disperse it with sodium tungstate at a mass ratio of 20:1 in deionized water, and evaporate t...

Embodiment 2

[0029] The preparation of catalyst: get styrene monomer and methacrylic acid, after sodium bicarbonate and deionized water are mixed by the mass ratio of 10:1:0.24:85, add the ammonium persulfate that massfraction is 0.4% in the mixture as triggering agent, under nitrogen protection, 80 o C, reacted under stirring conditions for 10h. The reaction products were subjected to evaporative self-assembly after centrifugal washing to prepare polystyrene templates. Cerium carbonate and zirconium nitrate with a molar ratio of 7:3 were fully dissolved in a mixed solution of water, citric acid, and ethylene glycol with a mass ratio of 10:5:3, and then adsorbed by a polystyrene template and dried. The product was subsequently treated with 4 o C / min rate of heating up to 350 o C, calcined for 1.5 h, then heated to 650 o C, calcination for 4 h to obtain nanoscale ordered honeycomb framework of cerium-zirconium oxide. Disperse it and tungsten chloride in deionized water at a mass ratio ...

Embodiment 3

[0032] The preparation of catalyst: get styrene monomer and methacrylic acid, sodium bicarbonate and deionized water, after mixing by the mass ratio of 11:2:0.24:85, add the benzyl peroxide that massfraction is 0.5% in mixture Acyl as initiator, under nitrogen protection, 75 o C, reacted for 8h under stirring conditions. The reaction products were subjected to evaporative self-assembly after centrifugal washing to prepare polystyrene templates. After cerium nitrate and zirconium oxychloride with a molar ratio of 6:4 are fully dissolved in a mixed solution of water, citric acid, and ethylene glycol with a mass ratio of 10:5:3, they are adsorbed by a polystyrene template and dried. The product was subsequently treated with 2 o C / min rate of heating up to 350 o C, calcined for 2 h, then heated to 550 o C, performing a calcination treatment for 3 hours to obtain an ordered honeycomb framework of cerium-zirconium oxide. Disperse it and phosphotungstic acid in deionized water a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com