A triggering system of thyristor switched capacitor valve set

A thyristor switching, thyristor valve technology, applied in flexible AC transmission systems, reactive power adjustment/elimination/compensation, etc. problem, to achieve the effect of easy circuit startup, easy integration, and simple realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

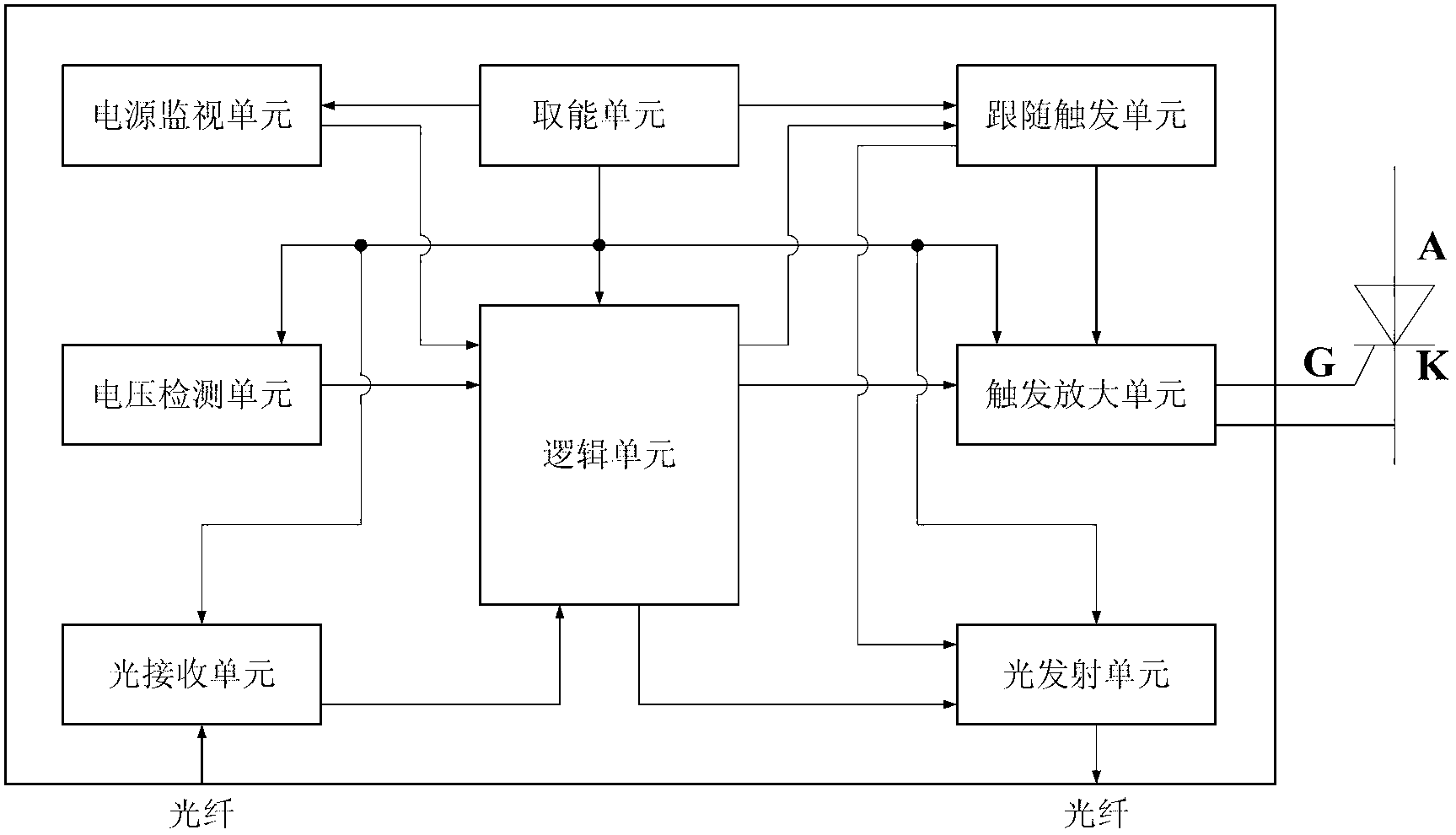

[0037] Such as figure 1 As shown, the present invention provides a thyristor switching capacitor valve group trigger system for switching the thyristor valve group. The thyristor valve group includes several thyristor units connected in series, and each thyristor unit consists of two thyristor units. Thyristors connected in antiparallel to each other; the trigger system includes an energy-taking unit, a logic unit, a power monitoring unit, a voltage detection unit, a light receiving unit, a follow-up trigger unit, a trigger amplification unit and a light emitting unit, wherein:

[0038] The energy-taking unit obtains the energy required to trigger the system to work from the high potential;

[0039] The power monitoring unit is connected to the energy harvesting unit, detects the energy harvesting voltage, and sends a fault signal to the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com