Pressure sensor dielectric medium isolation packaging structure and packaging method of same

A pressure sensor and medium isolation technology, applied in the field of sensors, can solve the problems of high cost, complex packaging process, complicated installation, etc., and achieve the effect of avoiding the process of filling silicone oil and reducing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

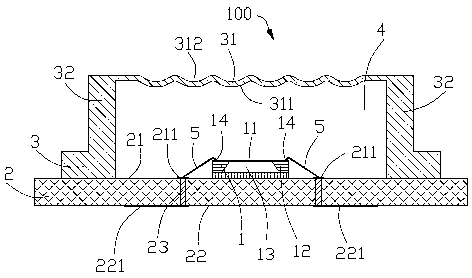

[0050] Please refer to figure 1 As shown, the pressure sensor medium isolation package structure 100 of the present invention includes a pressure sensor chip 1, a substrate 2 for carrying the pressure sensor chip 1, a bonding wire 5, and a pressure sensor chip fixed on the substrate 2 and surrounded by the pressure sensor chip 1. Peripheral cover body 3 . The pressure sensor chip 1 includes a pressure sensitive film 11 , a silicon substrate 12 , a back cavity 13 formed on the silicon substrate 12 , and an electrode 14 located on the silicon substrate 12 . The substrate 2 includes a front side 21 , a back side 22 opposite to the front side 21 , and a metallized hole 23 passing through the front side 21 and the back side 22 . In addition, the substrate 2 further includes inner pins 211 on the front side 21 and outer pins 221 on the back side 22 . The bonding wire 5 is connected to the electrode 14 of the pressure sensor chip 1 and the inner pin 211, and the metallized hole 23 ...

no. 2 approach

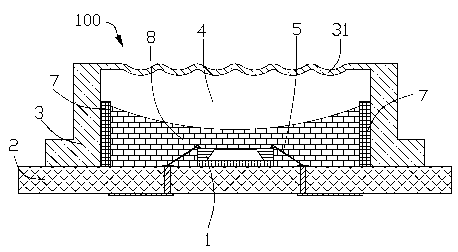

[0056] Please refer to figure 2 As shown, the difference between the pressure sensor medium isolation package structure 100 in the second embodiment of the present invention and the first embodiment is that the pressure sensor medium isolation package structure 100 also has a The cofferdam part 7 on the inner surface of the side wall 32 and the potting glue 8 located within the range of the cofferdam part 7 . The dam component 7 is located on the periphery of the pressure sensor chip 1 to limit the coverage of the encapsulant 8 . The potting glue 8 covers the pressure sensor chip 1 and the bonding wire 5 . The potting compound 8 has characteristics such as low shrinkage and small stress, such as silicon rubber, etc., and is used to protect the pressure sensor chip 1 and the bonding wire 5 . At the same time, the gas pressure in the airtight cavity 4 can be transmitted to the pressure sensitive membrane 11 through the potting glue 8 .

[0057] The cofferdam component 7 not ...

no. 3 approach

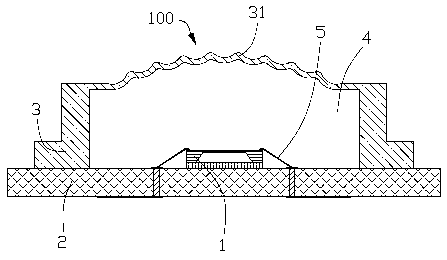

[0059] Please refer to image 3 As shown, the difference between the medium isolation packaging structure 100 of the pressure sensor in the third embodiment of the present invention and the first embodiment is that the top wall 31 of the cover body 3 is convex upward as a whole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com