A Correction Method for Angle Tilt of Line Scan Camera

A technology of line array camera and angle tilt, which is applied in the direction of measuring inclination, measuring devices, instruments, etc. It can solve the problems of difficulty in achieving complete consistency and the influence of correction results, and achieve the effect of good stability, high precision and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

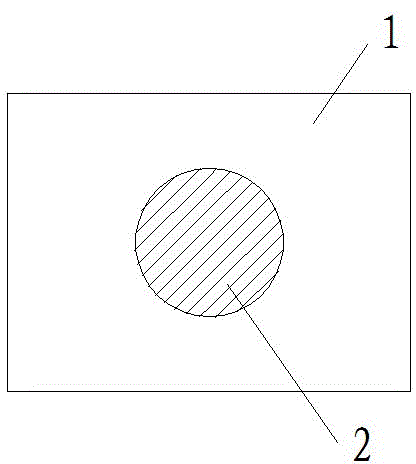

[0021] like figure 1 As shown, for the calibration plate used for calibration in the present invention, the target area of the calibration plate is circular, and there is no requirement for the placement angle of the calibration plate, and it is still circular when rotated at any angle. The diameter of the target area is equal to three-quarters of the scanning width of the line scan camera, and the accuracy of the target area is required to be equal to 1 micron, effectively ensuring the accuracy of the scanning results. The color of the target area is black, and the color of the background area of the calibration plate is white. Since the color of the circular target area of the calibration plate has a high contrast with the background area, it can facilitate fast and convenient scanning.

[0022] The specific steps of the correction method of the present invention are: (1) scan a correction plate with a line array camera to obtain the image of the correction plate; (2) ...

Embodiment 2

[0024] The rest is the same as that of Embodiment 1, except that the diameter of the target area is greater than three quarters of the scan width of the line scan camera, effectively ensuring the accuracy of the scan result.

Embodiment 3

[0026] The rest are the same as in Embodiment 1, except that the color of the target area is white, and the color of the background area is black. The color of the target area and the background area have a high contrast, which can help to scan quickly and conveniently.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com