Self-warming type thermochemical heat accumulating device and application

A heat storage device and thermochemical technology, applied in the direction of heat storage equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problems such as the improvement of heat temperature grade without considering the time difference between heat supply and demand, the contradiction between space difference, etc. The effect of storing heat temperature grade, small heat loss and reducing equipment volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

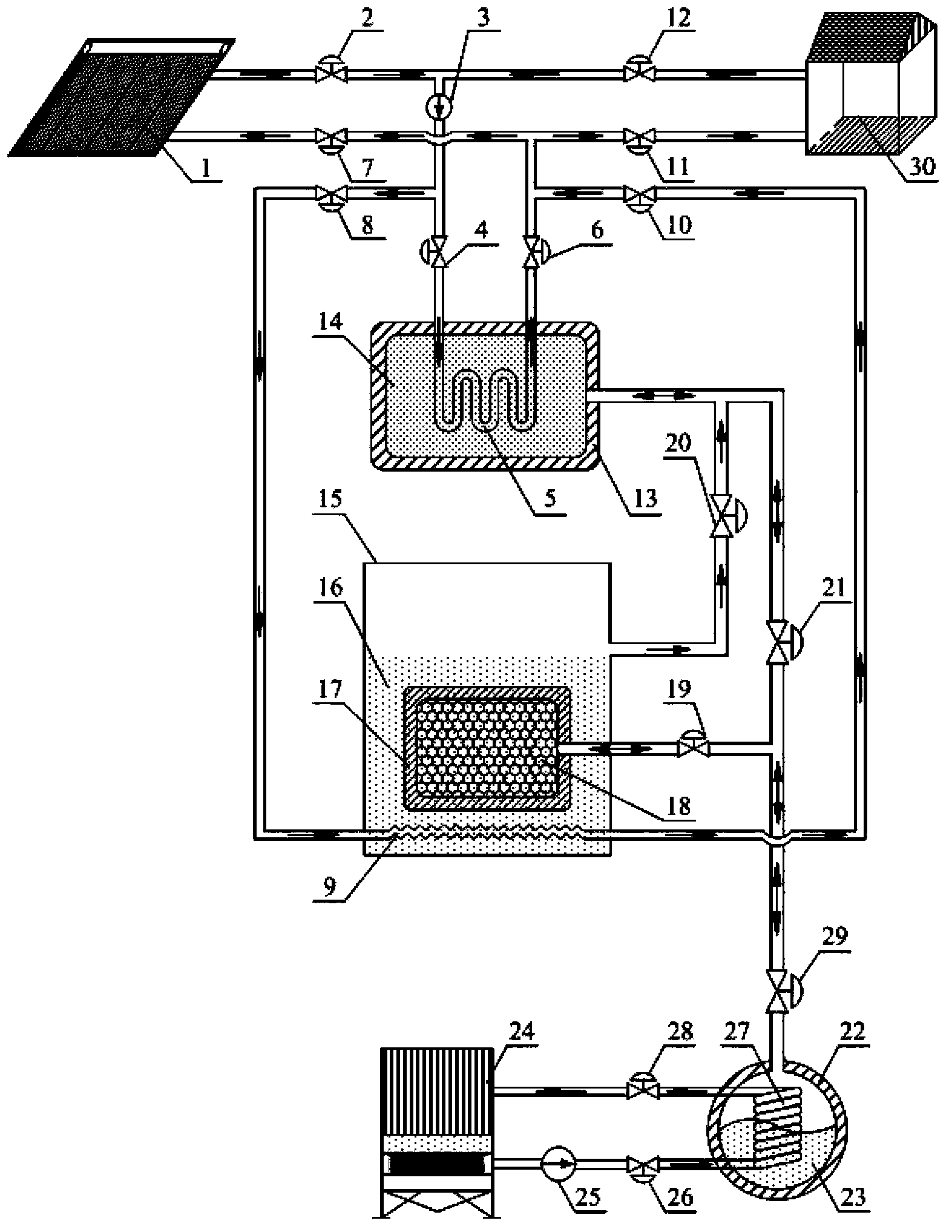

[0037] The structure of the self-heating thermochemical heat storage device is as follows: figure 1 As shown, including: low-grade heat energy collector 1, heating switching valve 2, heating heating circulation pump 3, control regulating valve 4, main reactor heat exchange tube bundle 5, control regulating valve 6, heating switching valve 7, heating switching valve 8. Auxiliary reservoir heating coil 9, heating switching valve 10, heating control valve 11, heating control valve 12, main reactor 13, main chemical adsorption reaction salt filled in the main reactor 14, auxiliary liquid storage Refrigerant 16, auxiliary reactor 17, auxiliary chemical adsorption reaction salt 18 filled in auxiliary reactor, control regulating valve 19, control regulating valve 20, control regulating valve 21, main storage Liquid container 22, main liquid storage filled with refrigerant 23, cooling tower 24, circulation pump 25, control regulating valve 26, main liquid storage heat exchange coil 27...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com