Device for recycling vent natural gas by hydrate method

A technology for venting natural gas and hydrate, applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of long investment recovery period, complicated operation and maintenance, and can only be vented for a long time, and achieves simple transportation process, simple and easy process flow. effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

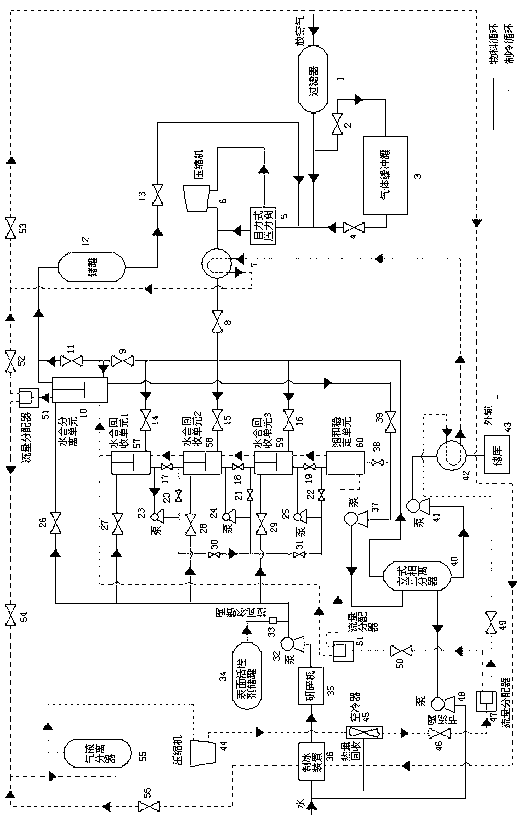

[0026] The implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0027] As shown in the accompanying drawings, the recovery method is: the device of the present invention consists of a filter 1, a one-way valve, a gas buffer tank 3, a self-operated pressure valve 5, a compressor, an evaporator, a hydration separation unit 10, a gas storage Tank 12, two-way air valve, stop valve, slurry pump, screw pump 32, Laval spray valve 33, surfactant storage tank 34, grinder 35; ice making device 36, vertical three-phase separator 40; storage 43. Air cooler 45, throttle valve 46, flow distributor, water pump 48, one-way valve; two-way valve 52; gas-liquid separator 55, hydration recovery unit and saturation stabilization unit composition 60.

[0028] It includes two processes of material circulation and refrigeration cycle; material circulation: the emptied natural gas enters the pipeline, and passes through the filter 1 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com