Photocatalyst water wax and preparation method thereof

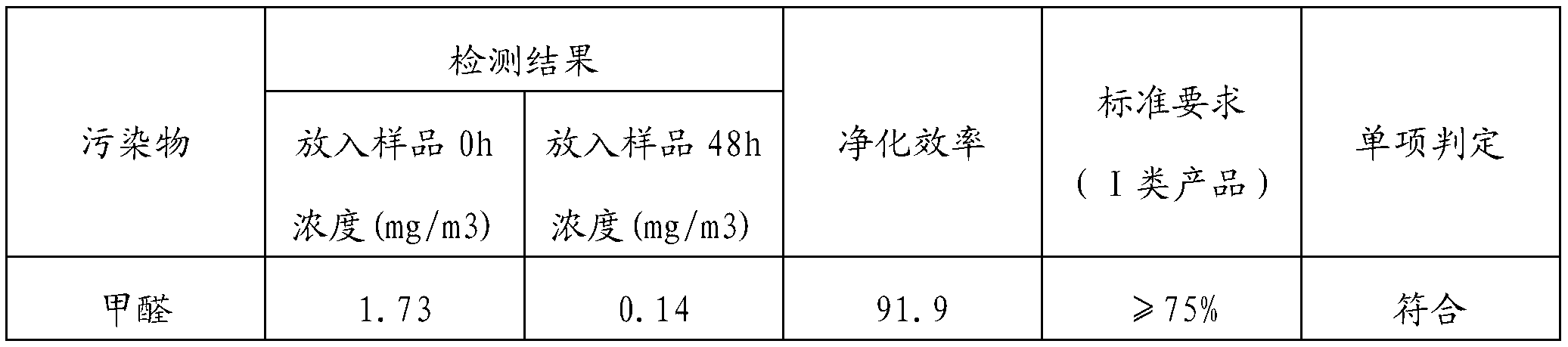

A photocatalyst and water wax technology, applied in wax coatings, antifouling/underwater coatings, and biocide-containing paints, etc., can solve problems such as reducing the function of functional coatings to remove formaldehyde, to protect furniture, protect long-term health, The effect of smooth and bright colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

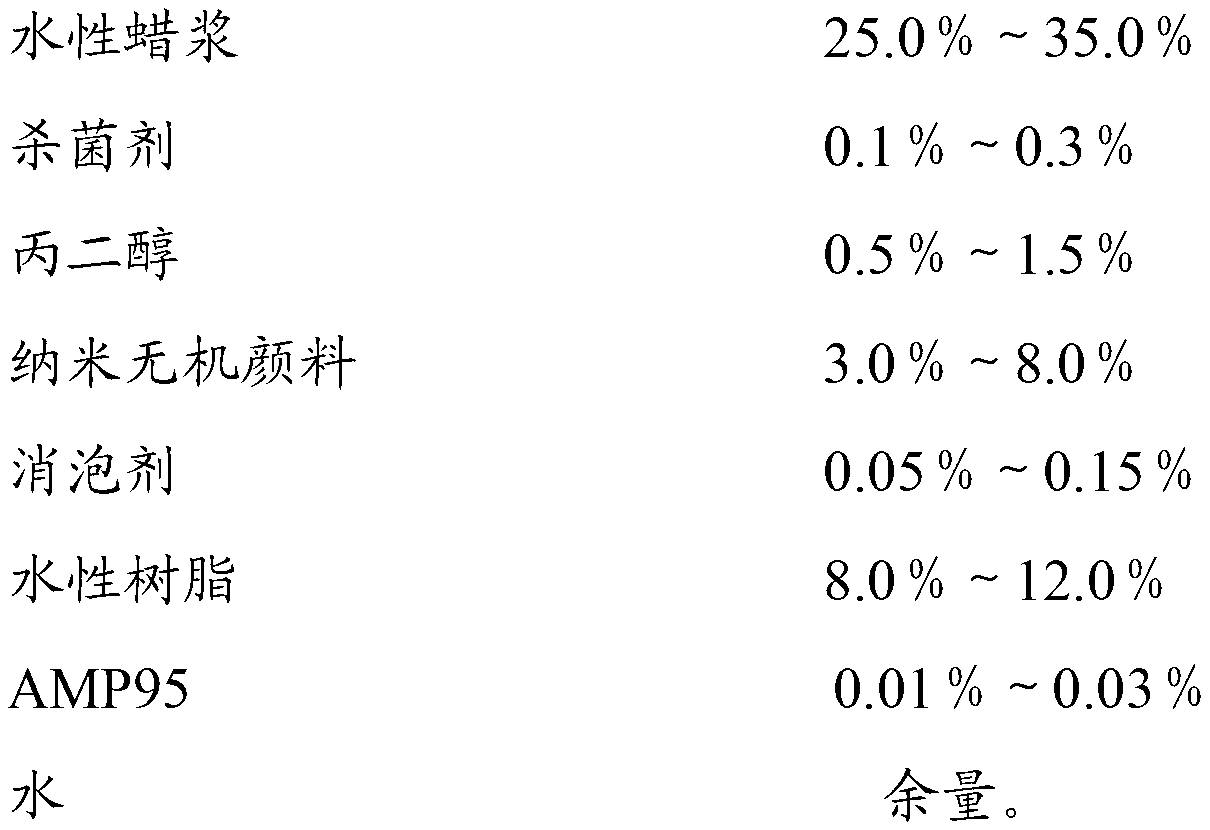

[0034] A photocatalyst water wax, comprising the following substances calculated by weight percentage: 25.0% water-based PP wax, 0.3% bactericide, 1.5% propylene glycol, 3.0% nano-scale silicon dioxide, 0.15% defoamer, 12.0% water-based resin, AMP950 .01% and water.

[0035] The method for preparing described photocatalyst water wax, comprises following preparation steps:

[0036] First, stir the above amount of photocatalyst, water-based wax slurry, bactericide, propylene glycol, nano-inorganic pigments, and water at 700rpm for 15min; then add the defoamer and stir for 15min at 700rpm; then add water-based The resin was stirred for 5 minutes; finally, the AMP95 was added and stirred for 15 minutes at 700 rpm to obtain the photocatalyst water wax.

Embodiment 2

[0038] A photocatalyst water wax, comprising the following substances calculated by weight percentage: 30.0% water-based paraffin, 0.2% bactericide, 1.0% propylene glycol, 5.0% nano inorganic pigment, 0.1% defoamer, 10.0% water-based resin, AMP950.02% and water.

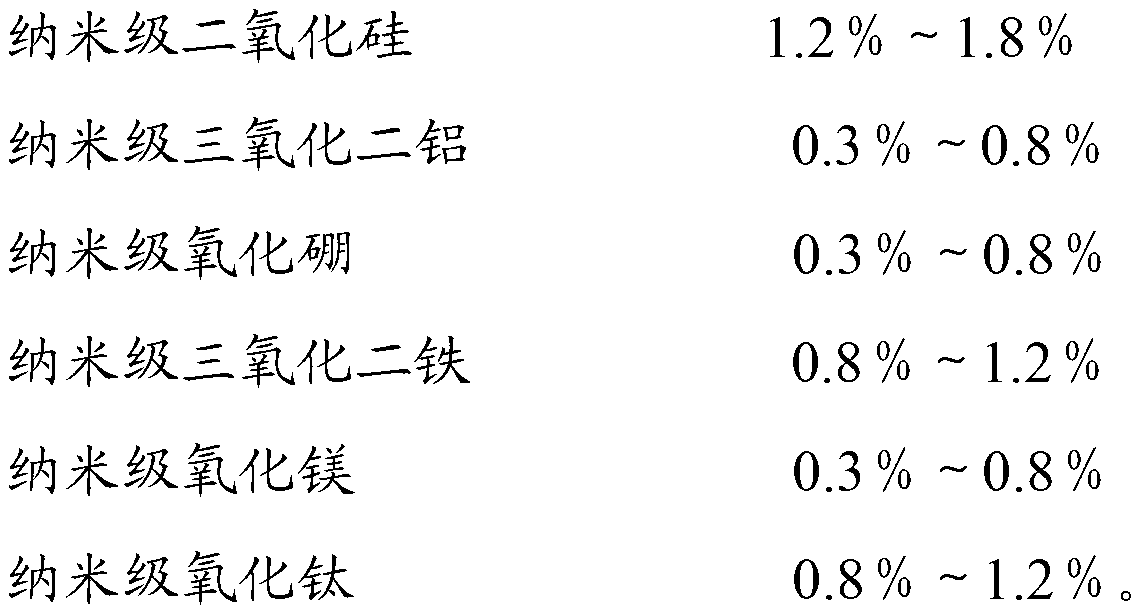

[0039] Wherein, the nano-inorganic pigment is obtained by mixing the following substances calculated by weight percentage: 1.5% of nano-scale silicon dioxide, 0.5% of nano-scale aluminum oxide, 0.5% of nano-scale boron oxide, and 0.5% of nano-scale It is prepared by stirring 1.0% iron, 0.5% nano-sized magnesium oxide and 1.0% nano-sized titanium oxide by stirring at 1000 rpm for 30 minutes.

[0040] The method for preparing described photocatalyst water wax, comprises following preparation steps:

[0041] First, stir the above amount of photocatalyst, water-based wax slurry, bactericide, propylene glycol, nano-inorganic pigments, and water at 800rpm for 10min; then add the defoamer and stir at 900rpm for 10min; then...

Embodiment 3

[0043] A photocatalyst water wax, including the following substances calculated by weight percentage: 30.0% water-based PE wax, 0.2% bactericide, 1.0% propylene glycol, 5.0% nano inorganic pigment, 0.1% defoamer, 10.0% water-based resin, AMP950.02 % and water.

[0044]Wherein, the nano-inorganic pigment is obtained by mixing the following substances calculated by weight percentage: 1.2% of nano-scale silicon dioxide, 0.8% of nano-scale aluminum oxide, 0.3% of nano-scale boron oxide, and 0.3% of nano-scale It is prepared by stirring 0.8% iron, 0.8% nano-sized magnesium oxide and 1.1% nano-sized titanium oxide at 900 rpm for 35 minutes.

[0045] The method for preparing described photocatalyst water wax, comprises following preparation steps:

[0046] First, stir the above amount of photocatalyst, water-based wax slurry, bactericide, propylene glycol, nano-inorganic pigments, and water at 800rpm for 10min; then add the defoamer and stir at 800rpm for 10min; then add water-based...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com