Step pitch changing mechanism

A technology of step distance and material shaft, which is applied in the field of mechanical processing, can solve the problems of low step distance change accuracy, affect product quality, machine wear and other problems, and achieve the effect of high step change precision, good continuity and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

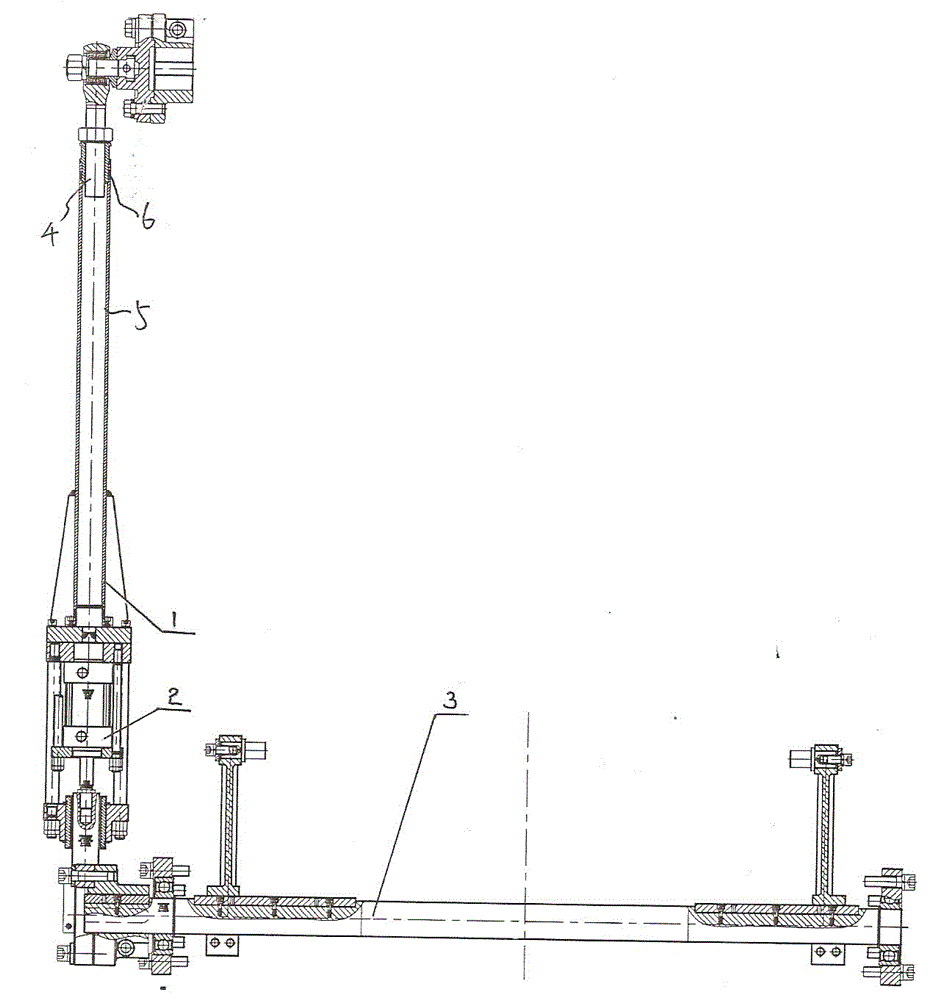

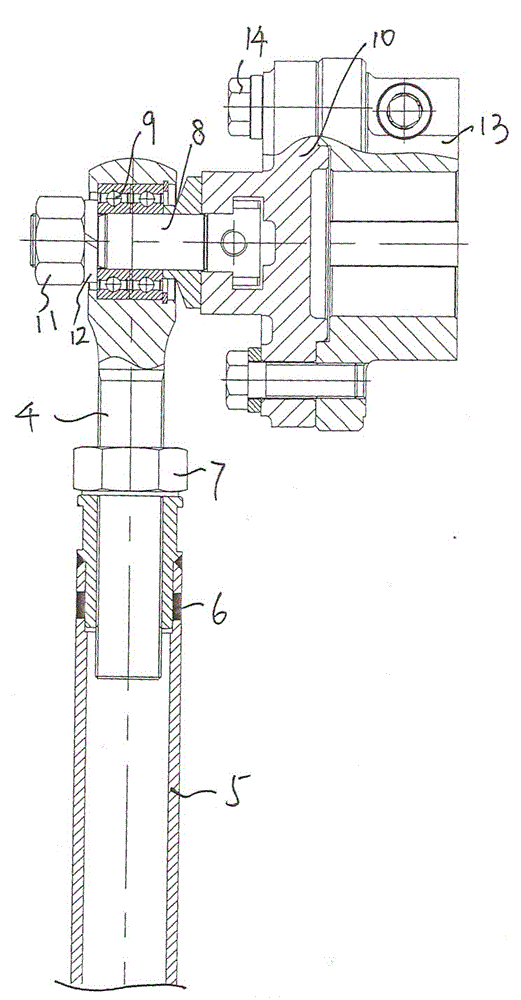

[0020] A material pulling step conversion mechanism, including an eccentric device 1, a single-double step conversion part 2 and a material pulling shaft part 3, wherein the eccentric device includes a connecting rod, the upper end of the connecting rod is connected to the eccentric part through a bearing, and the lower end of the connecting rod is connected to the eccentric part. Single and double-step conversion parts are connected. The connecting rod is divided into upper and lower sections 4 and 5 that are connected to each other, and is sealed with a sealing ring 6. The nut 7 plays a pressing role, and the shaft 8 is matched with the bearing 9, and then connected with the eccentric part. The nut 11 plays the role of fastening; the spring washer 12 plays the role of anti-loosening;

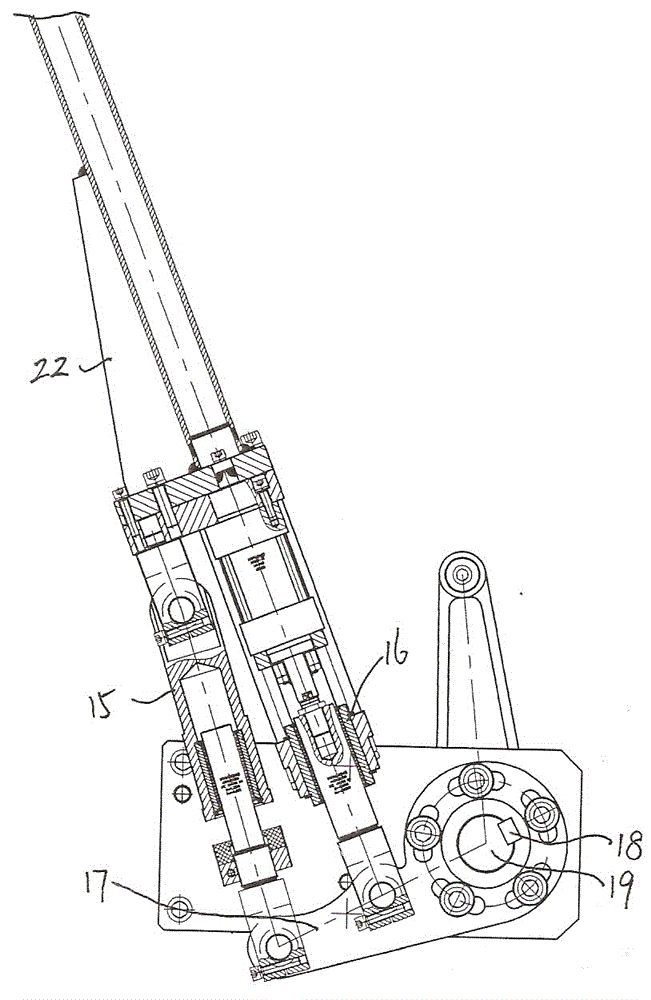

[0021] Said single and double-step conversion components include first and second cylinders 15 and 16, the upper ends of the first and second cylinders are connected with the connecting rod 5 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com