Body attitude adaptive adjustment active suspension actuator, system and control method

An adaptive adjustment, active suspension technology, applied in suspension, elastic suspension, vehicle components, etc., can solve problems such as pressure loss, high risk of oil leakage, long oil pipelines, etc., to attenuate shock and vibration , to avoid the effect of excessive temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0038] In order to clearly and completely describe the technical solution of the present invention and its specific working process, with reference to the accompanying drawings, the specific embodiments of the present invention are as follows:

[0039] In the present invention, unless otherwise expressly specified and limited, the terms "installed", "connected", "connected", "fixed" and other terms should be understood in a broad sense, for example, it may be a fixed connection or a detachable connection , or integrated; it can be a mechanical connection or an electrical connection; it can be directly connected or indirectly connected through an intermediate medium, it can be the internal connection of two elements or the interaction relationship between the two elements, unless otherwise specified limit. For those of ordinary skill in the art, the specific meanings of the above terms in the present invention can be understood according to specific situations.

[0040] In the...

Embodiment 1

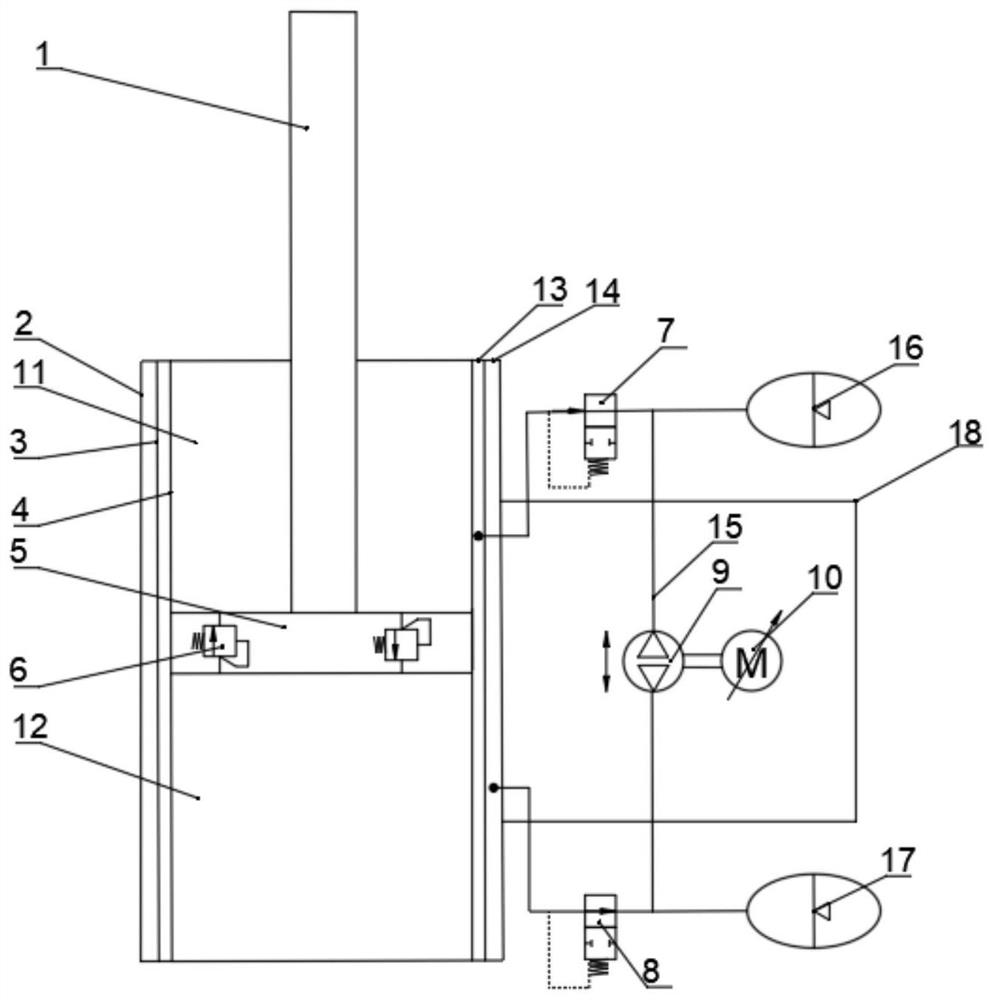

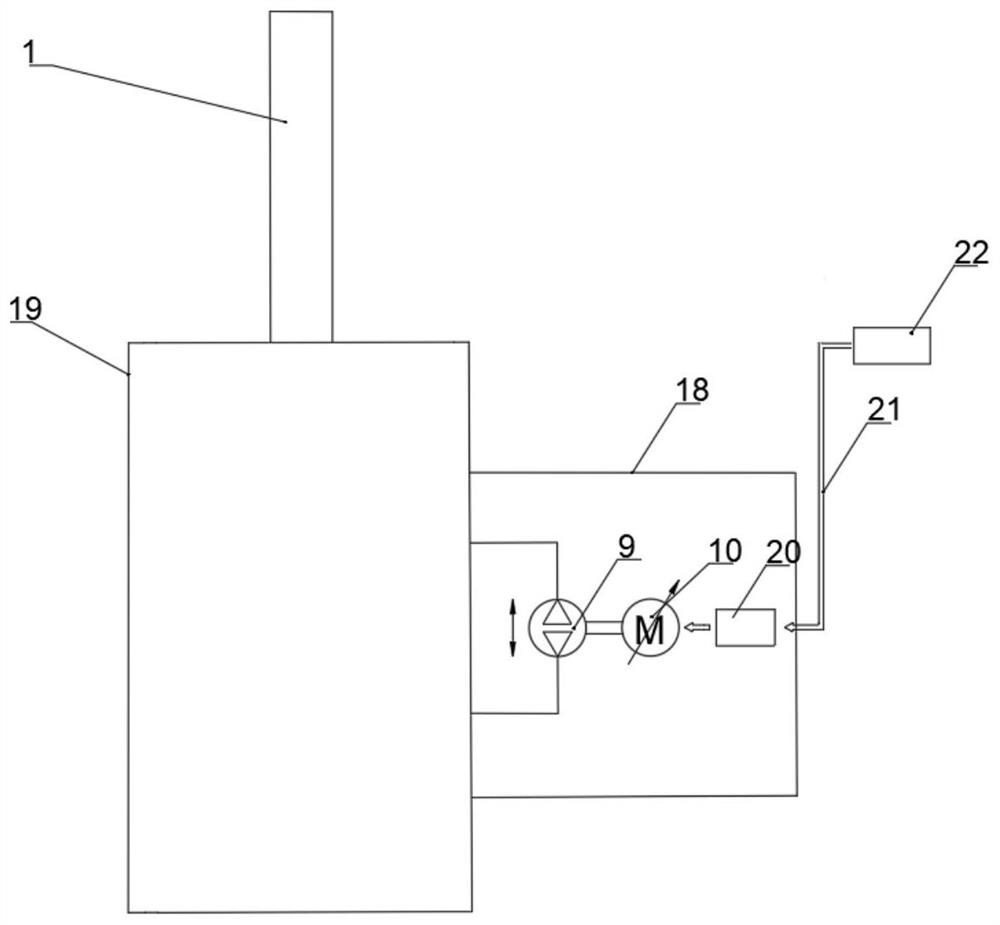

[0043] The first embodiment discloses an active suspension actuator for self-adaptive adjustment of body posture, such as figure 1 As shown, the active suspension actuator includes: motor 10, hydraulic pump 9, oil storage cylinder 2, intermediate cylinder 3, working cylinder 4, piston head 5, piston rod 1, unloading valve 6, inner throttle valve 7 , the outer throttle valve 8, the inner accumulator 16 and the outer accumulator 17; wherein:

[0044]The piston head 5 is installed in the working cylinder 4, the outer circumference of the piston head 5 is sealingly connected with the inner side wall of the working cylinder 4, the piston rod 1 is vertically installed at the middle position of the outer end face of the piston head 5, and the working cylinder 4 Among them, the rod cavity where the piston rod 1 is located, that is, the cavity formed between the outer end face of the piston head 5 and the working cylinder 4 is the recovery cavity 11, and the rodless cavity of the worki...

Embodiment 2

[0051] The second embodiment discloses a control method for adaptively adjusting the body posture of an active suspension actuator, where the active suspension actuator is the active suspension actuator described in the first embodiment, and the specific control process is as follows:

[0052] When it is detected that the wheel is about to travel to the bump on the road, the control motor 10 rotates clockwise to drive the hydraulic pump 9 to rotate clockwise, and the hydraulic pump 9 pushes the oil through the intermediate oil circuit 15 into the inner oil circuit 13, and then measures the oil from the inside. The passage 13 passes through the inner throttle valve 7 and the oil storage cavity in turn, and finally flows into the recovery cavity 11. The oil pressure in the recovery cavity 11 increases, pushing the piston head 5 to the side of the compression cavity 12, which in turn drives the The piston rod 1 is retracted inward to reduce the height of the vehicle body, so as to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com