Brick making system device

A technology of system equipment and brick making machine, which is applied in auxiliary molding equipment, manufacturing tools, ceramic molding workshops, etc., can solve the problems of high fuel consumption, high labor intensity, low work efficiency, etc., to reduce the size of material particles, reduce Labor intensity, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

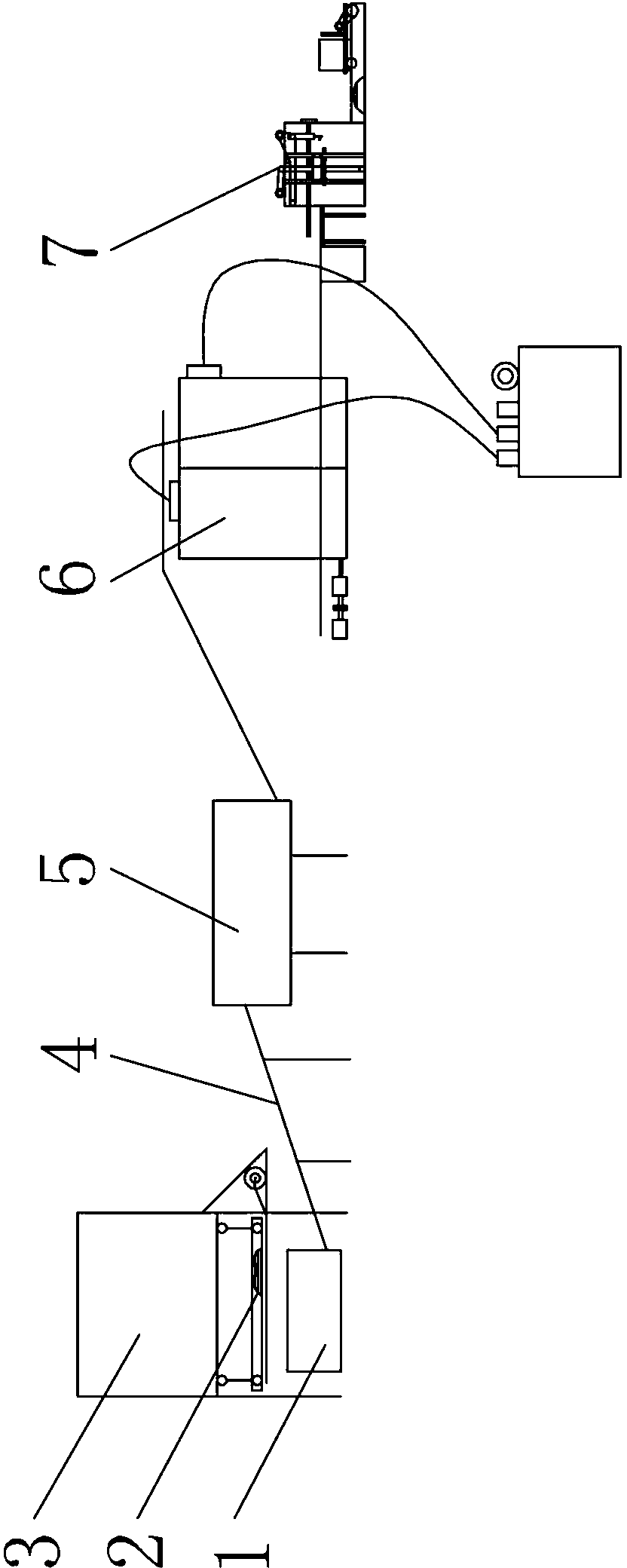

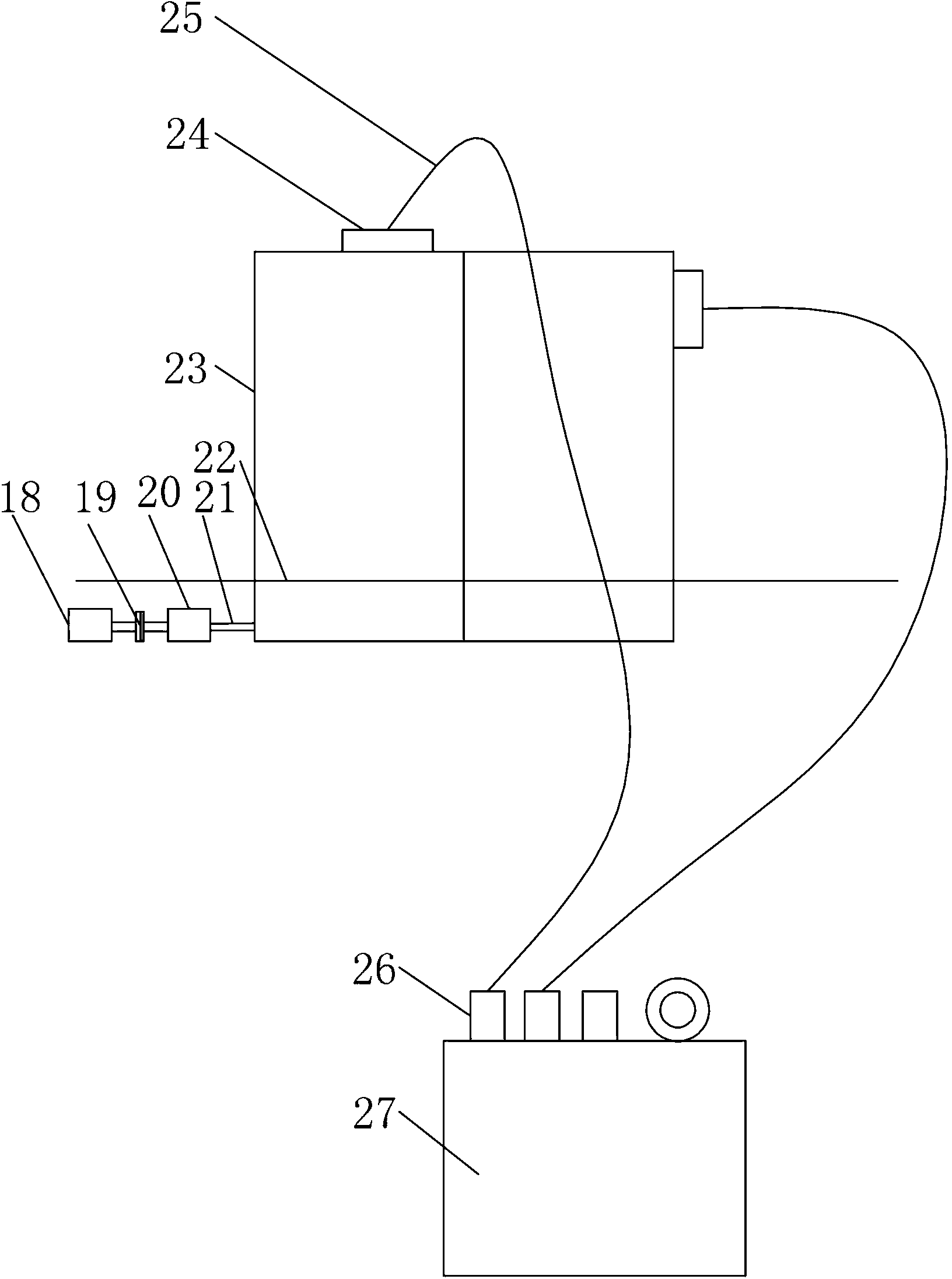

[0022] As shown in the figure: the three-box batching machine vibration device is installed between the three-box batching machine and the weighing device, the pipeline of the brick making machine is changed and the automatic plate loading machine matched with the brick making machine is added; the outlet of the weighing device passes through the conveyor The belt is connected to the feed port of the mixer, and the discharge port of the mixer is connected to the feed box of the brick making machine through a conveyor belt.

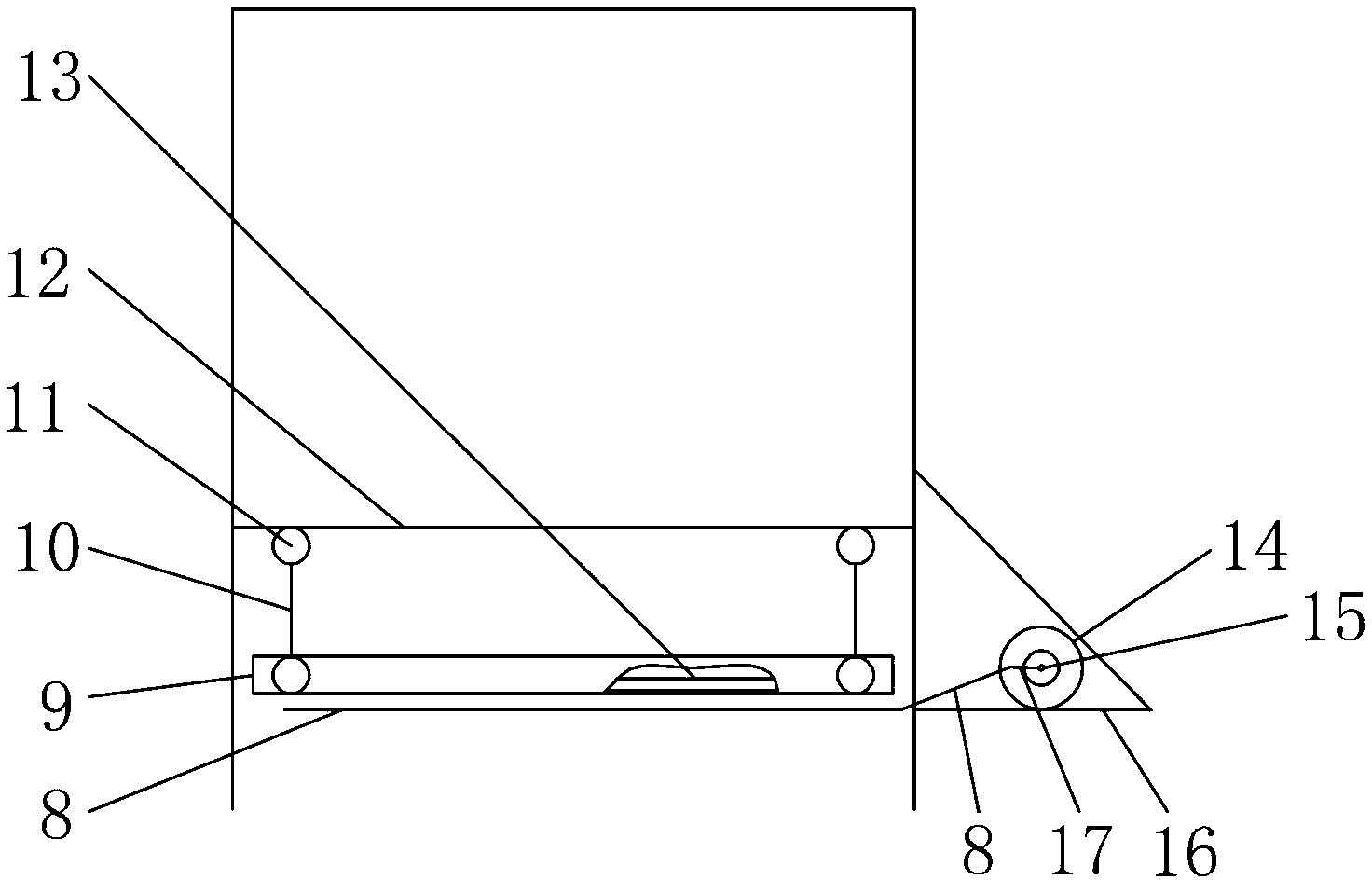

[0023] In the vibration device of the three-box batching machine, the bottom of the batching machine frame is connected to the screen frame through bearings and swing rods, the screen is arranged on the screen frame, and the vibration connecting rod is arranged below the screen frame. The vibration connecting rod is a Y-shaped structure, and the vibration The converging end of the connecting rod is connected with the movable rod, and the movable rod is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com