Horizontal type six-shaft parallel-serial computer numerical control milling machine

A CNC milling machine and hybrid technology, which is used in metal processing machinery parts, metal processing equipment, feeding devices, etc., can solve the problem of small processing space, and achieve the effect of large working space, good rigidity performance and short error transmission chain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

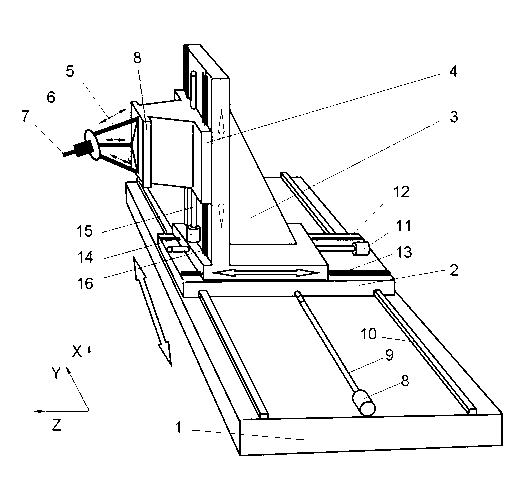

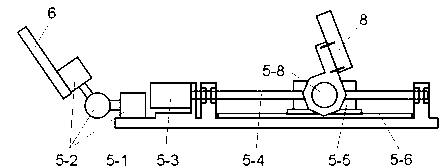

[0012] Below in conjunction with accompanying drawing, the patent of the present invention is described further.

[0013] The horizontal 6-axis hybrid CNC milling machine shown in the figure is characterized in that the tool pose control of the milling machine is driven and controlled by 6 servo motors. The milling machine includes a 3-degree-of-freedom series mechanism and a 3-degree-of-freedom parallel mechanism. The parallel mechanism is fixed The seat is fixedly connected to the execution end of the series mechanism, and the execution end of the parallel mechanism is equipped with a processing tool; the 3-DOF series mechanism includes a base 1, a Y-direction mobile platform 2, a Z-direction mobile platform 3 and an X-direction mobile platform 4 , the base 1 is provided with a Y-direction rail 10 and a Y-direction drive motor 8, the Y-direction rail 10 is provided with a Y-direction mobile platform 2, the Y-direction mobile platform is provided with a Y-direction drive screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com