Process for selecting marmatite from high ferric sulphide ore

A technology for sulfide ore and sphalerite, which is applied in flotation, solid separation and other directions, can solve the problems of increasing the production cost and environmental protection cost of the concentrator, unfavorable long-term development of the concentrator, and increasing the cost of tailings water treatment, etc. Achieve the effect of reducing heavy metal ion content, saving non-ferrous metal resources and reducing treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

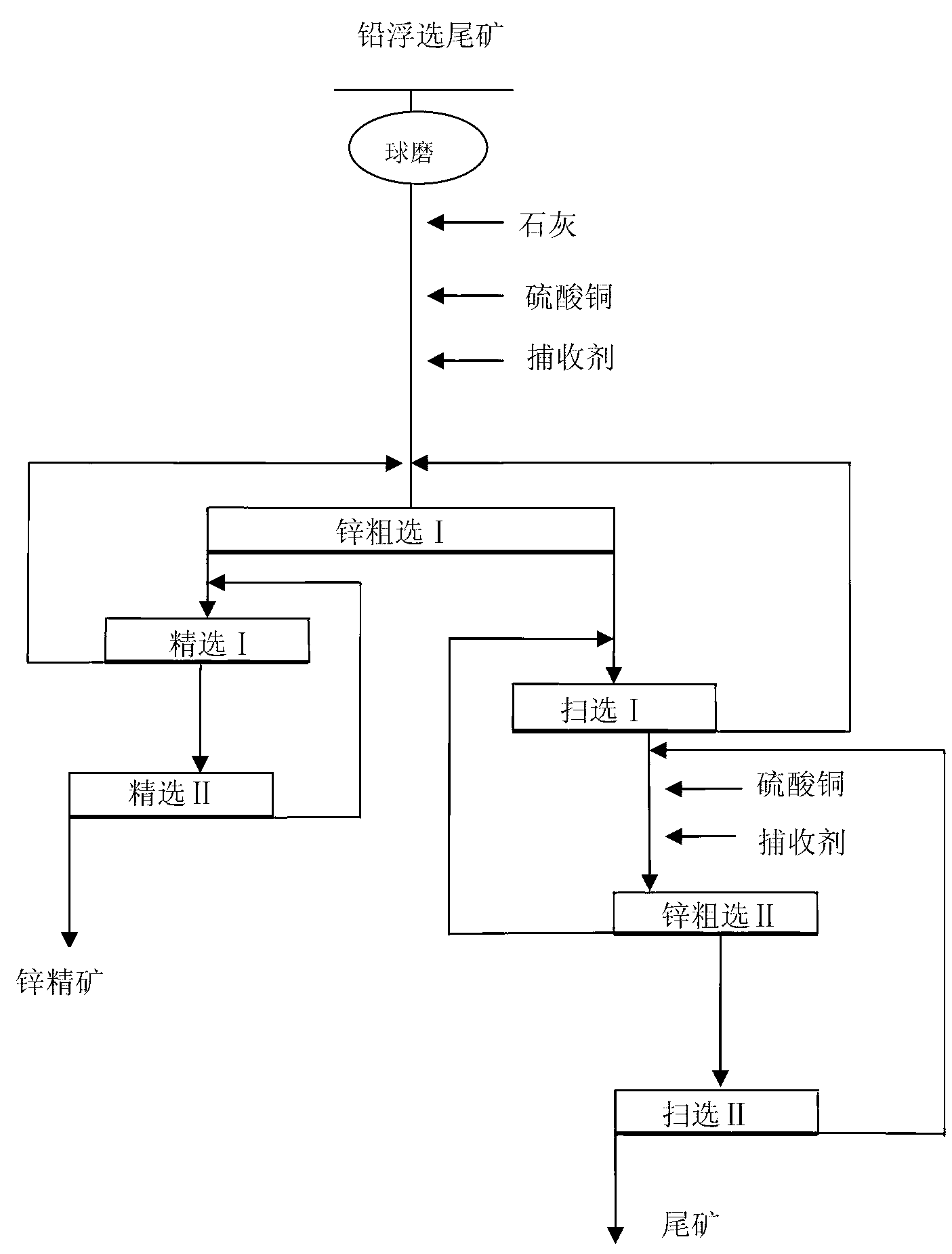

[0023] Such as figure 1 Shown, a kind of process that selects sphalerite from high-iron sulfide ore:

[0024] ① Grinding: after ball milling the lead flotation tailings, enter the mixing tank;

[0025] ②Zinc roughing Ⅰ: add 1kg / t of lime, 600g / t of copper sulfate, and 76g / t of collector into the mixing tank according to each ton of raw ore, and select zinc rough concentrate and primary tailings; the collector It is Z-200 collector;

[0026] ③Concentration: The above-mentioned rough zinc ore is subjected to concentration I, and then concentration II is carried out after concentration I to obtain zinc concentrate. Ⅰ Reelection;

[0027] ④Primary tailings treatment:

[0028] a. The primary tailings from zinc roughing are carried out to sweeping I; the foam product produced after sweeping I is returned to roughing I for re-election.

[0029] b. After sweeping, add copper sulfate 200g / t and collector 28g / t to carry out zinc roughing II; the collector is Z-200 collector.

[00...

Embodiment 2

[0032] A kind of process of selecting iron sphalerite from high-iron sulfide ore:

[0033] ① Grinding: after ball milling the lead flotation tailings, enter the mixing tank;

[0034] Raw ore properties: The main metal minerals are pyrite, sphalerite, galena, lead carbonate, lead vanadium, smithsonite and so on. Gangue minerals are mainly iron hydroxide, manganese hydroxide, calcite, clay minerals, weathered silicate, quartz, mica, etc. Lead and zinc mainly exist as sulfides.

[0035] ② Zinc roughing Ⅰ: add 0.8kg / t of lime, 690g / t of copper sulfate, and 63g / t of collector into the mixing tank for each ton of raw ore, and select zinc rough concentrate and primary tailings;

[0036] ③Concentration: the above-mentioned rough zinc ore is subjected to concentration I, and after concentration I, then concentration II is carried out to obtain zinc concentrate;

[0037] ④Primary tailings treatment:

[0038] a. The primary tailings from zinc roughing are carried out to sweeping I; ...

Embodiment 3

[0042] A kind of process of selecting iron sphalerite from high-iron sulfide ore:

[0043] ① Grinding: after ball milling the lead flotation tailings, enter the mixing tank;

[0044] Raw ore properties: The main metal minerals are pyrite, sphalerite, galena, lead carbonate, lead vanadium, smithsonite and so on. Gangue minerals are mainly iron hydroxide, manganese hydroxide, calcite, clay minerals, weathered silicate, quartz, mica, etc. Lead and zinc mainly exist as sulfides.

[0045] ② Zinc roughing Ⅰ: add 1.2kg / t of lime, 560g / t of copper sulfate, and 68g / t of collector into the mixing tank for each ton of raw ore, and select zinc rough concentrate and primary tailings;

[0046] ③Concentration: the above-mentioned rough zinc ore is subjected to concentration I, and after concentration I, then concentration II is carried out to obtain zinc concentrate;

[0047] ④Primary tailings treatment:

[0048] a. The primary tailings from zinc roughing are carried out to sweeping I; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com