Porous silicon-carbide carrier surface gradient pore molecular sieve coating and preparation method thereof

A technology of porous silicon carbide and silicon carbide carrier, applied in molecular sieve catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as reducing catalyst utilization, catalyst deactivation, and reducing target product selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

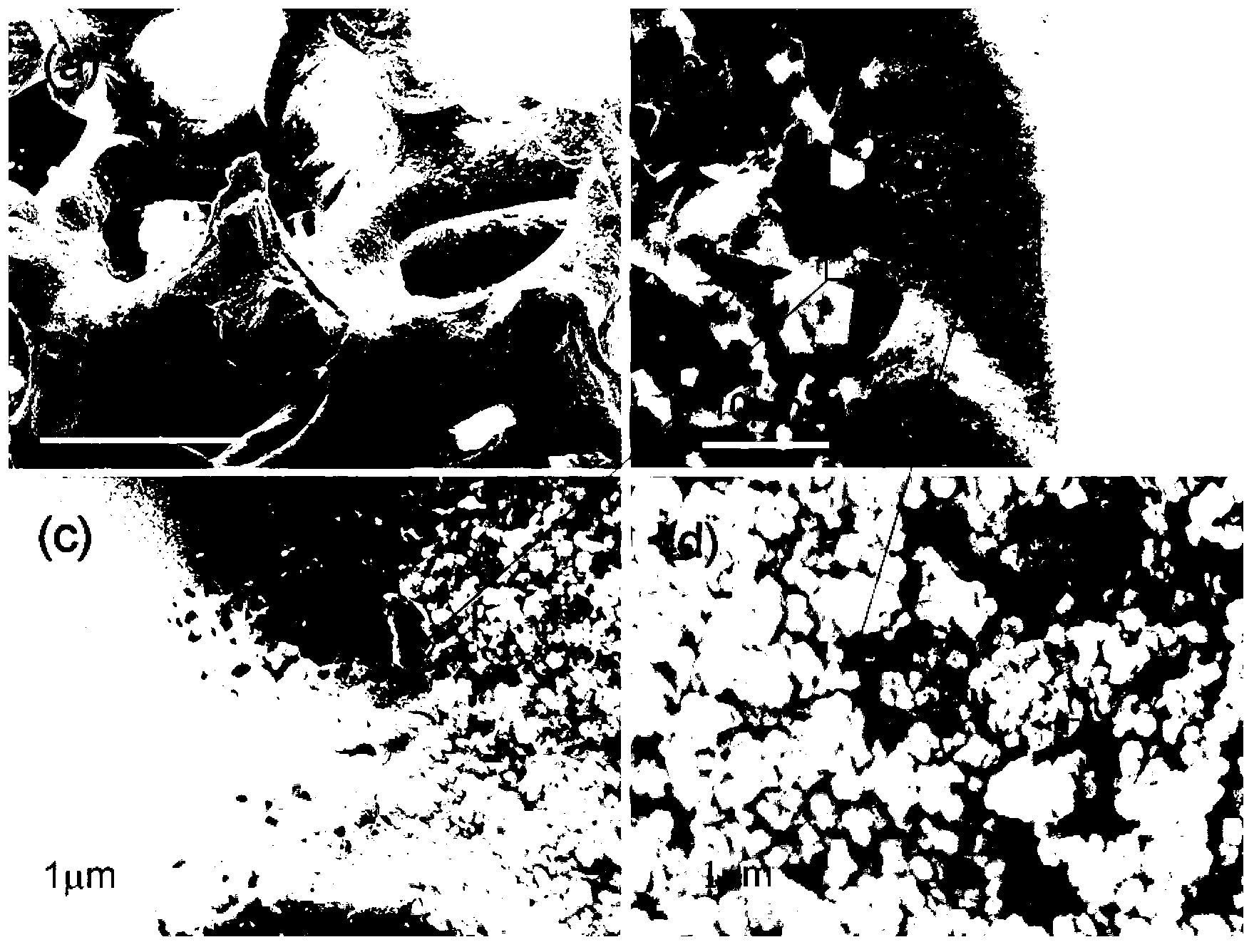

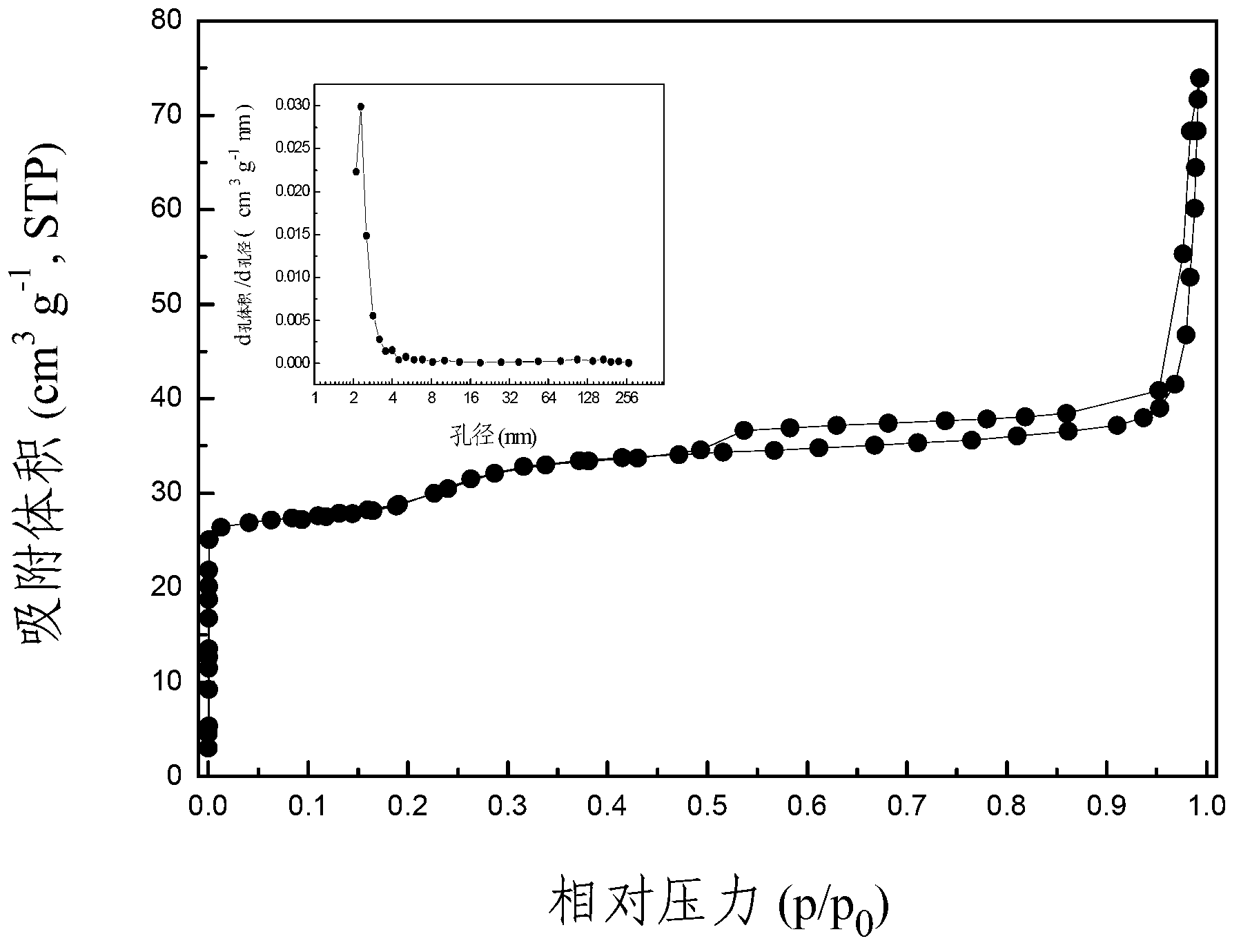

[0050] The preparation method of the gradient pore molecular sieve coating on the surface of the porous silicon carbide carrier of the present invention, the structural coating is realized by two-step coating combined with steam treatment; first, the colloidal molecular sieve precursor is coated on the surface of the foamed silicon carbide carrier; after that, the coating A mixture of colloidal molecular sieve precursors, molecular sieve crystals and pore-forming agents; finally, through steam treatment, the molecular sieve precursors are converted into molecular sieve crystals and achieve a firm bond between the coating and the carrier; by controlling the colloidal molecular sieve precursors and molecular sieves The ratio of crystals and the addition of pore-forming agents can adjust the porosity of the coating. Specific steps are as follows:

[0051] Step (1), coating the colloidal molecular sieve precursor on the surface of the foamed silicon carbide carrier;

[0052] Imme...

Embodiment 1

[0060] In this example, the preparation method of the gradient pore ZSM-5 molecular sieve coating on the surface of the foamed silicon carbide carrier:

[0061] First, prepare the colloidal ZSM-5 molecular sieve precursor: mix silica sol, aluminum isopropoxide, tetrapropylammonium hydroxide, and deionized water in a molar ratio of 1:0.01:0.10:19, and wait for the silica sol to be completely hydrolyzed , put the above solution in a reaction kettle for hydrothermal synthesis, and hydrothermally synthesize at 130° C. for 6 hours to obtain a colloidal molecular sieve precursor. Immerse the foamed silicon carbide carrier in the molecular sieve precursor sol prepared by the above method for 1 minute, shake off the excess sol with a centrifuge, and dry at room temperature for 12 hours. This process was repeated 3 times.

[0062] Disperse 10 grams of molecular sieve crystals with a silicon-aluminum ratio of 100 and a particle size of 200 nanometers in 100 milliliters of the above-ment...

Embodiment 2

[0067] In this example, the preparation method of the gradient pore β-type molecular sieve coating on the surface of the foamed silicon carbide carrier:

[0068] First, the colloidal β-type molecular sieve precursor is prepared. Mix ethyl orthosilicate, sodium metaaluminate, tetraethylammonium hydroxide, and deionized water in a molar ratio of 1:0.5:0.5:20. After the tetraethyl orthosilicate was completely hydrolyzed, the above solution was placed in a reaction kettle, and hydrothermally synthesized at 140° C. for 48 hours to prepare the precursor of β ultrafine molecular sieve. Immerse the foamed silicon carbide carrier in the colloidal molecular sieve precursor for 20 minutes, blow off excess slurry, and dry at 65°C for 2 hours. This process is repeated twice.

[0069] Disperse 20 grams of β-type molecular sieve crystals with a silicon-aluminum ratio of 20 and a particle size of 100 nanometers in 100 milliliters of the above-mentioned colloidal molecular sieve precursor, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com