Fish killer

A fish killing machine and fish belly technology, which is applied in fish processing, slaughtering, food science, etc., can solve problems such as unrealizable, unstable, and non-adjustable transmission mechanisms, so as to reduce labor intensity, improve production efficiency, and achieve good quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

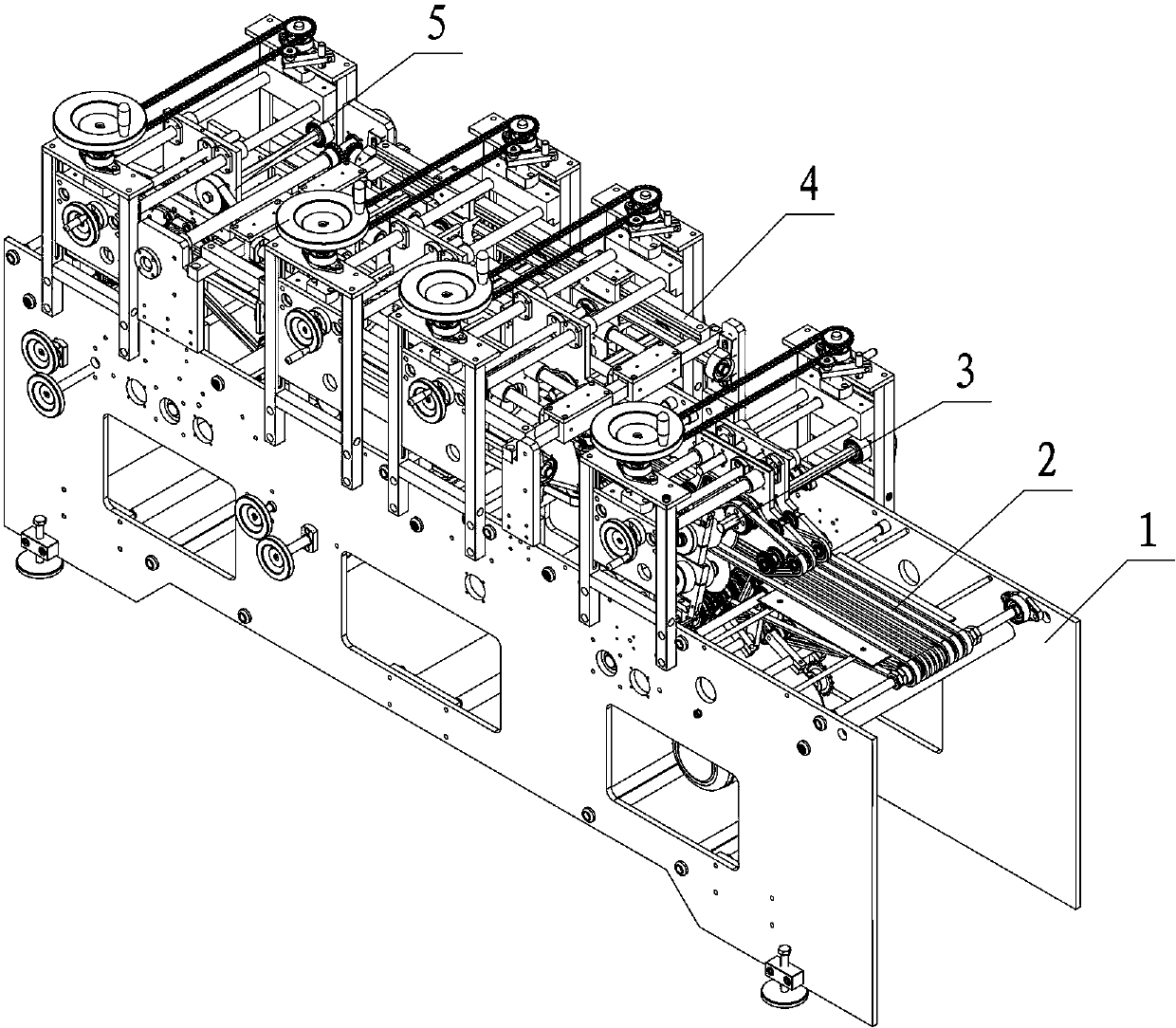

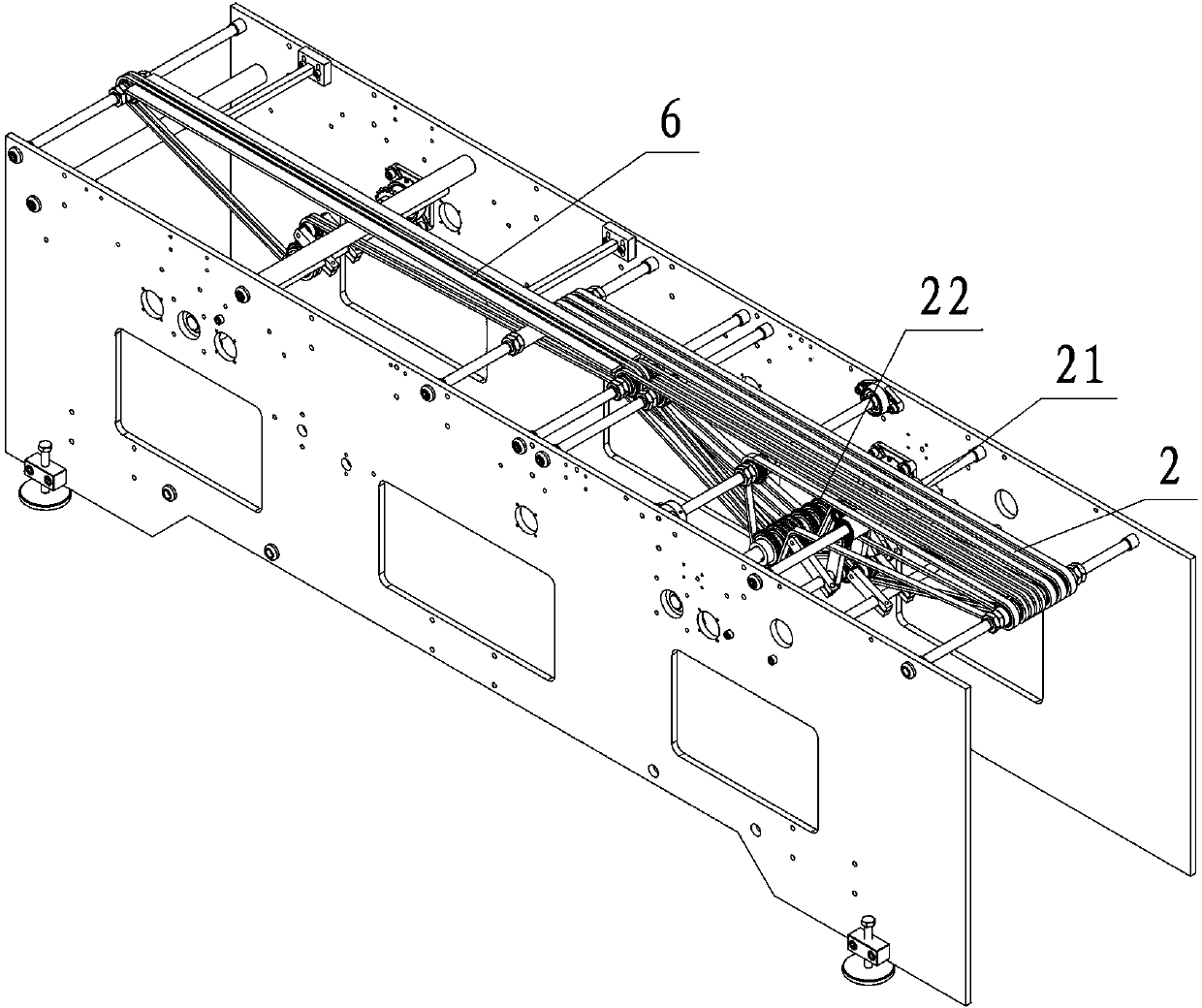

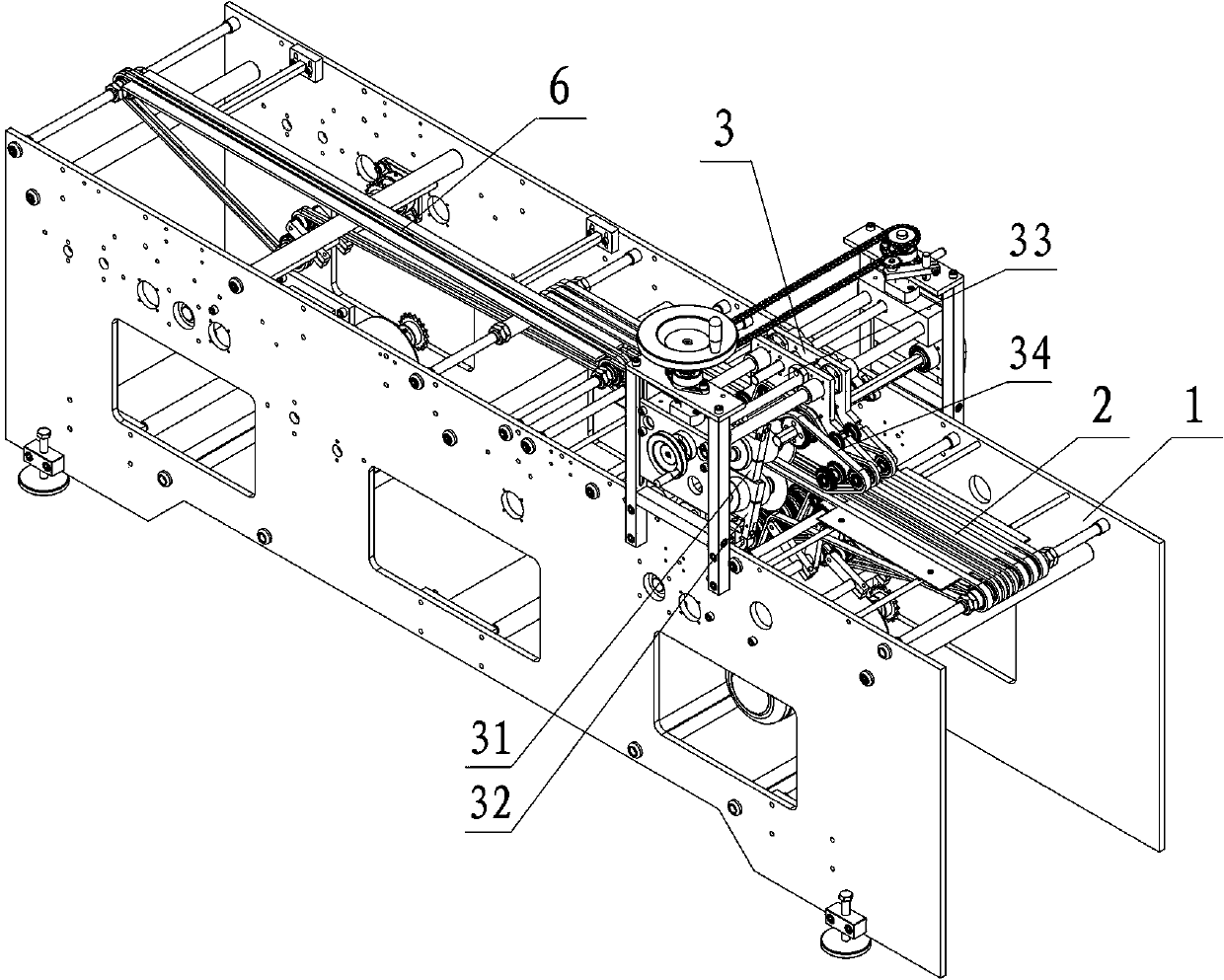

[0022] like figure 1 , 2 , 3, 4, 5, 6, 7, and 8 are shown as a specific embodiment of the fish killing machine of the present invention. This embodiment includes a frame 1, a speed differential transmission device 2, a fish head cutting device 3, a first fish belly cutting device 4 and a second fish belly cutting device 5, a speed differential transmission device 2, a fish head cutting device 3, a first fish belly cutting device The fish belly cutting device 4 and the second fish belly cutting device 5 are sequentially arranged on the frame 1, and the speed difference transmission device 2 includes a transmission chain group 21. The speed difference of 21 makes the fish body rotate, cut off the fish head through the fish head cutting device 3, enter the first fish belly cutting device 4 for sorting and can choose to cut the fish belly from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com