Novel cutting machine

A technology of cutting machine and cutting mechanism, which is applied in the direction of metal processing machinery parts, clamping, supporting, etc., can solve the problems of sliding knife, aluminum foil quality defect, affecting the production efficiency of aluminum foil, etc., achieve automatic continuous cutting, improve cutting efficiency, The effect of convenient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

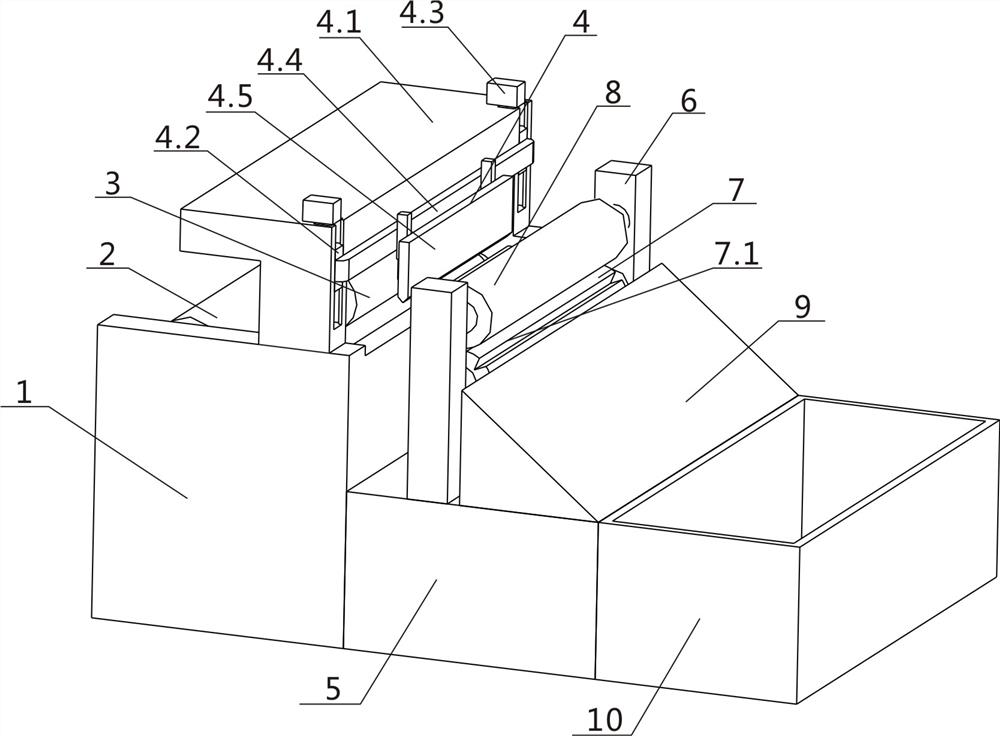

[0023] combined with Figure 1-3 The new type of cutting machine includes a frame 1, a conveying roller 2, a first pressure roller 3, a cutting mechanism 4, a receiving seat 5, a second pressure roller 8, a pick-up roller 7, a slide table 9 and an aluminum foil recovery box 10. A plurality of conveying rollers 2 are evenly distributed on the top surface of the frame 1, and the conveying rollers 2 can transport the aluminum foil to the direction of the cutting mechanism 4, and a first press is arranged above the conveying roller 2 at the cutting end of the frame 1. Roller 3, through the cooperation of the first pressure roller 3 and the lower conveying roller 2, can smoothly send the aluminum foil out of the cutting end of the frame 1, and can prevent the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com