Pipe laser cutting machine with continuous cutting function

A laser cutting machine, laser cutting technology, applied in laser welding equipment, welding/cutting auxiliary equipment, auxiliary devices, etc., can solve the problems of low cutting efficiency, waste of time, etc., and achieve the effect of improving efficiency and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

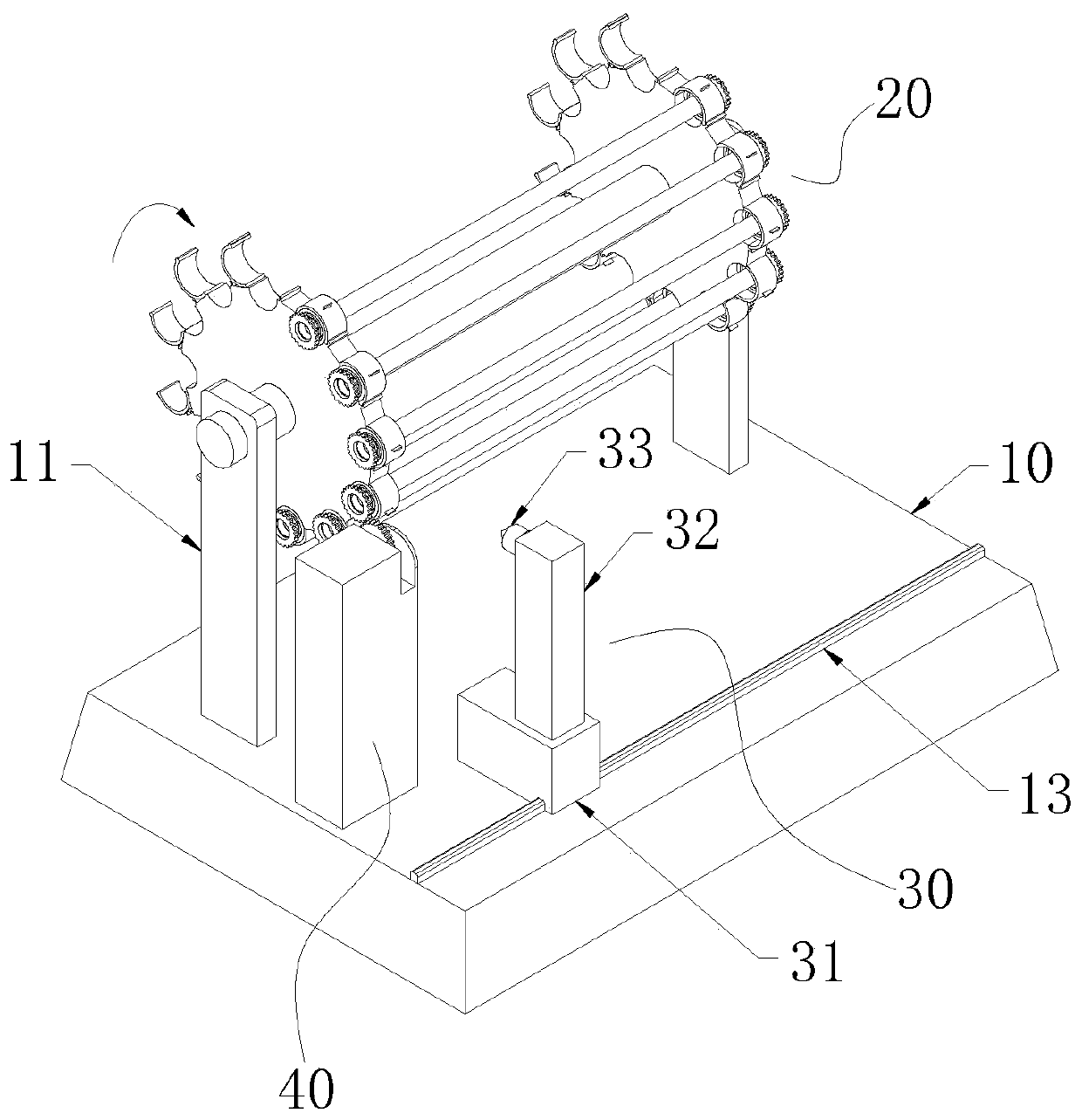

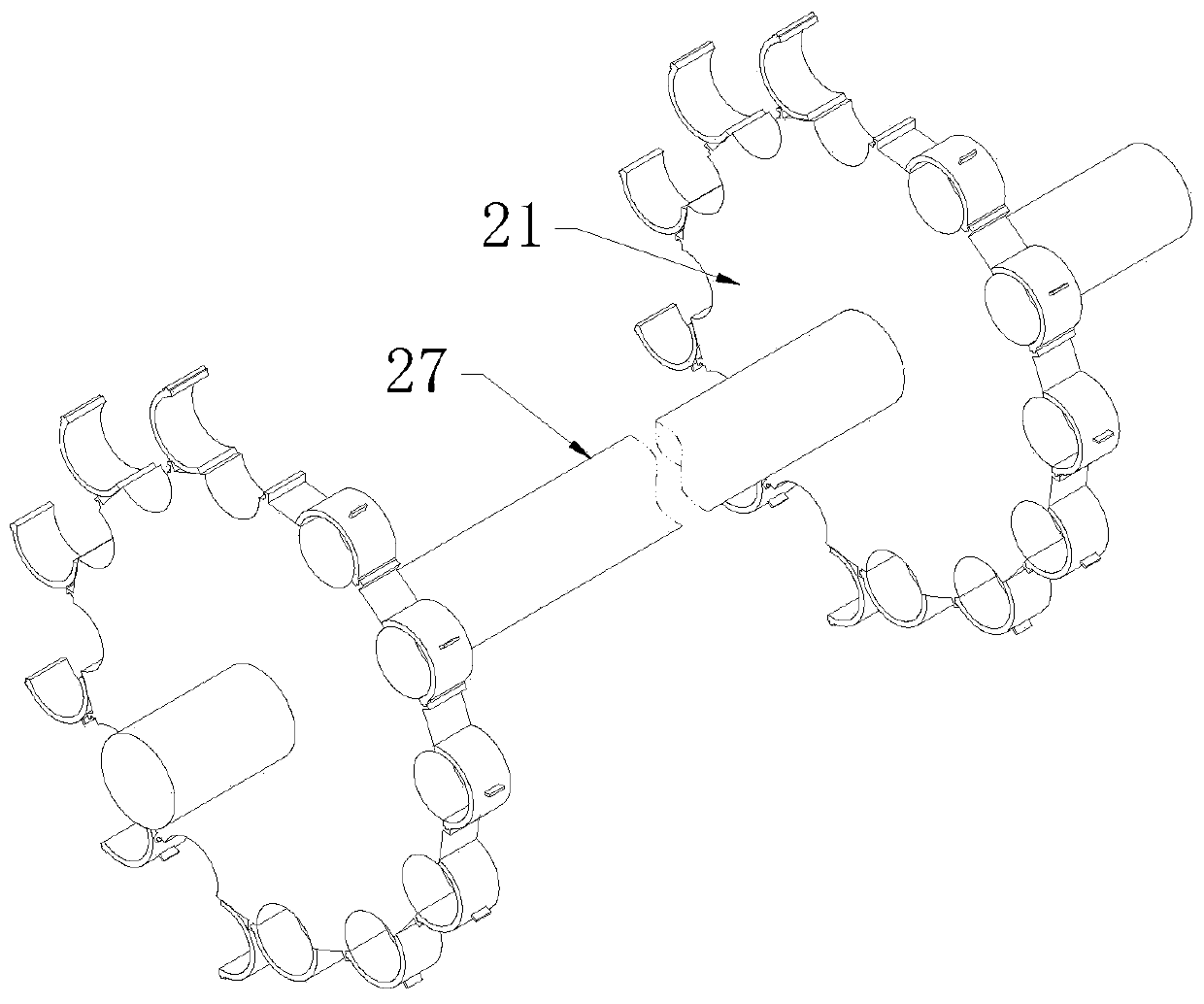

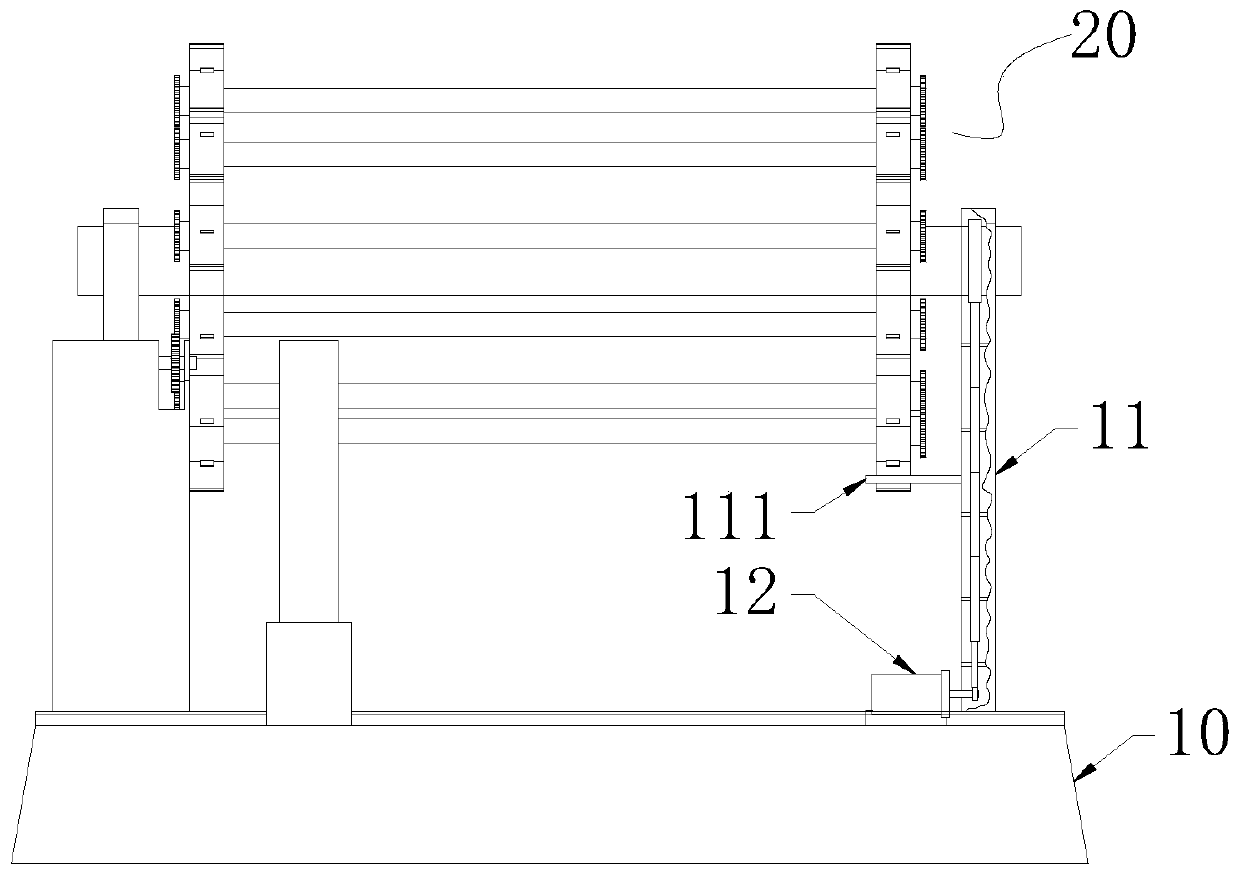

[0026] Such as figure 1 and 2 As shown, a continuous cutting pipe laser cutting machine includes a base 10, a self-rotating pipe fixing device 20 arranged on the top surface of the base 10, a laser cutting device 30 arranged on the side of the pipe fixing device 20, and a set Between the pipe fixing device 20 and the laser cutting device 30, there is a drive system 40 for driving the pipe to rotate. The pipe fixing device 20 includes a shaft 27 that rotates around the central axis and a shaft that is coaxially arranged with the shaft 27 for fixing the pipe. Chucks 21 , the chucks 21 are fixed on the shaft 27 and evenly distributed along the length direction of the shaft 27 .

[0027] The pipe falls on the chuck 21 through the feeding device, and is fixed on the chuck 21 by the fixing device. The shaft 27 is driven to rotate, which drives the pipe on the chuck 21 to rotate. When the pipe moves to the drive system 40, The shaft 27 loses its drive, the chuck 21 stops rotating, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com