A paper tube cutting device

A cutting device and paper tube technology, applied in metal processing and other directions, can solve the problem of manual loading and unloading, and achieve the effect of reducing manual labor, reducing operation difficulty, and reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

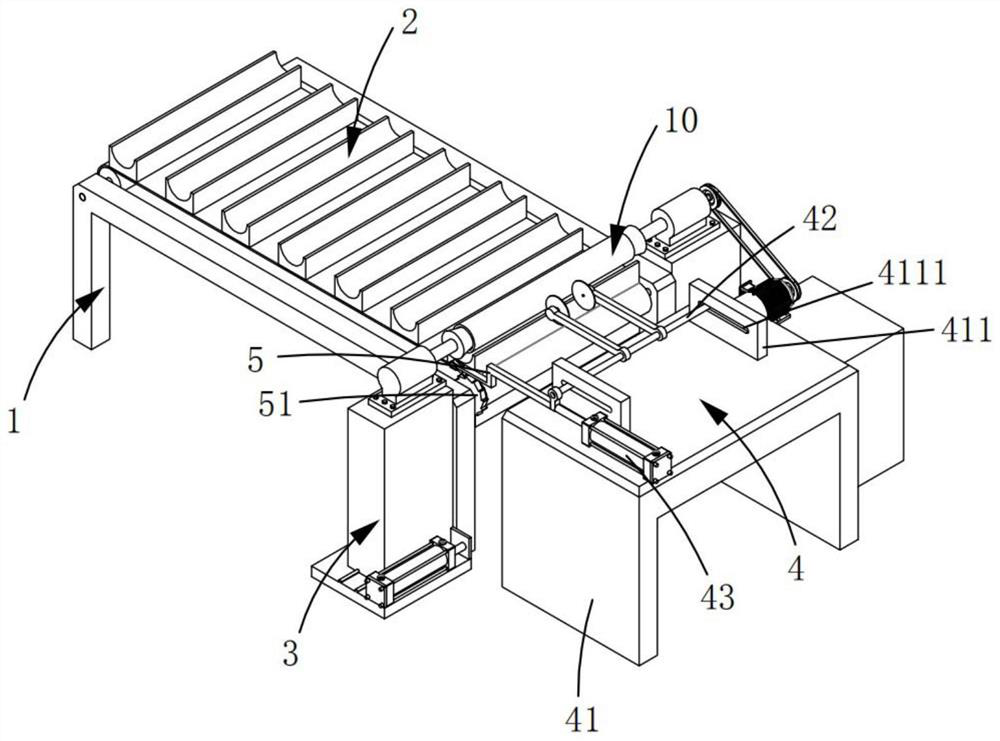

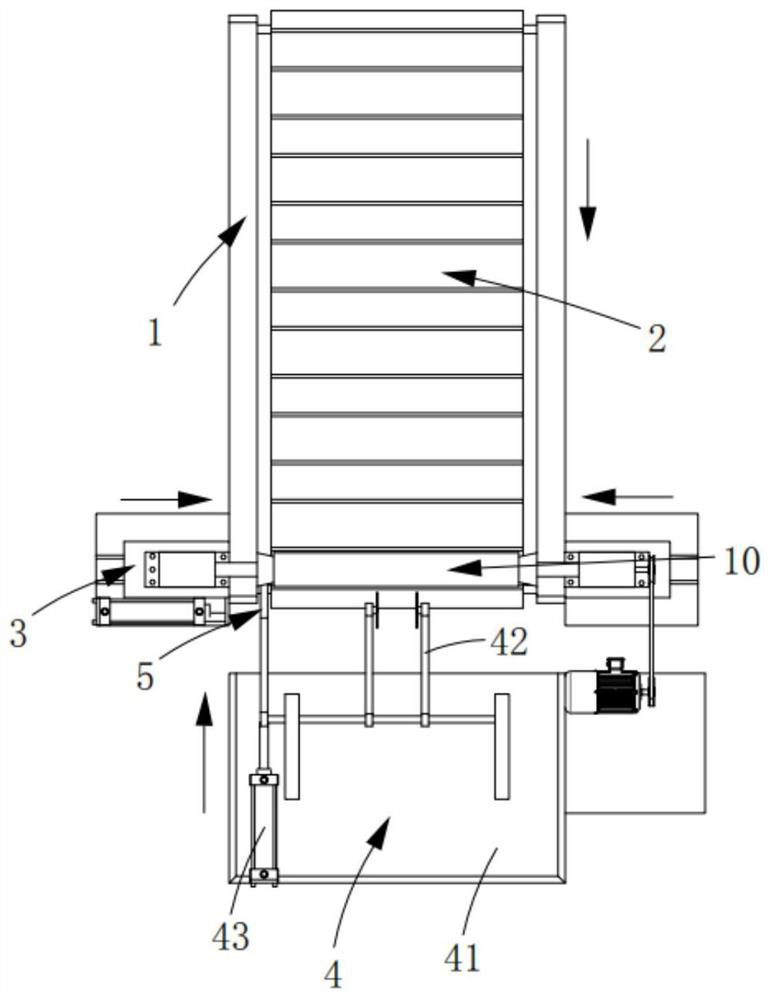

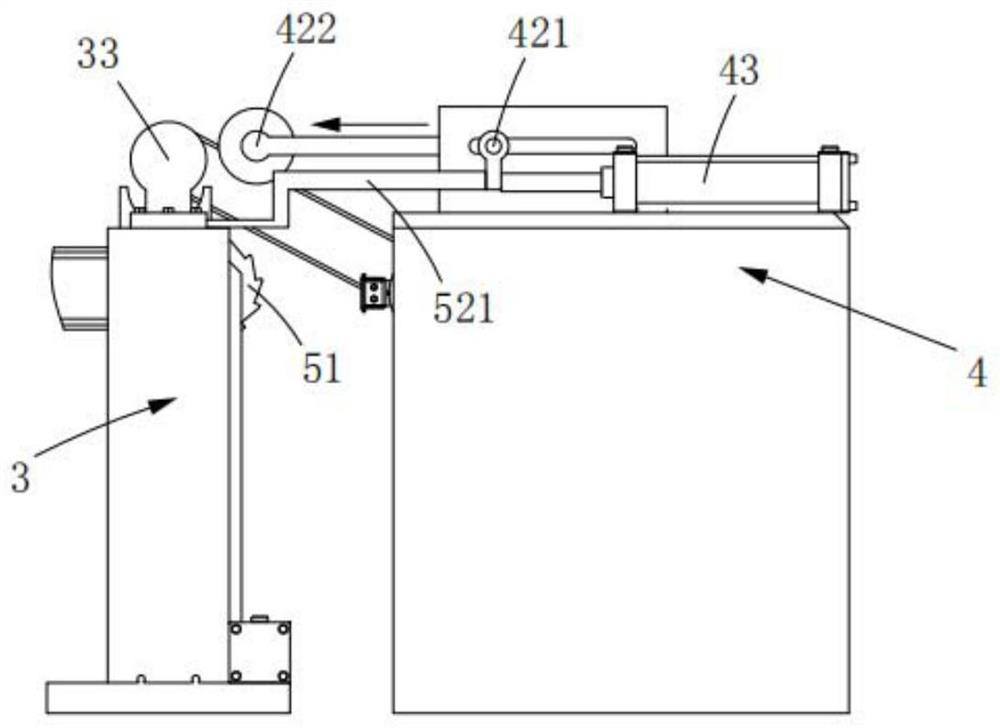

[0049] Such as figure 1 , 2 , 3 and 4, a paper tube cutting device comprising:

[0050] Rack 1;

[0051] Conveying mechanism 2, described conveying mechanism 2 is arranged on described frame 1, and it conveys workpiece 10 along the length direction of described frame 1, and this conveying mechanism 2 comprises first transmission roller 21, second transmission roller 22 and conveyor belt 23. The first transmission roller 21 and the second transmission roller 22 are rotatably arranged on the frame 1, and the conveyor belt 23 is set outside the first transmission roller 21 and the second transmission roller 22;

[0052] The two tightening mechanisms 3 are arranged symmetrically on both sides of the conveying mechanism 2, and they can tighten the two ends of the workpiece 10, and drive the workpiece 10 to rotate. The position of the tightening mechanism 3 corresponding to the conveying mechanism 2 is a cutting station;

[0053] Cutting mechanism 4, described cutting mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com