Manufacturing device and manufacturing method for light guide film

A technology for manufacturing devices and manufacturing methods, which is applied in the field of light-guiding film manufacturing devices, can solve problems such as limiting the thinning of light-guiding films, poor light transmittance, and poor light-guiding effects of light-guiding films, and achieves the improvement of thinness The effect of reducing the degree of thickness and reducing the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

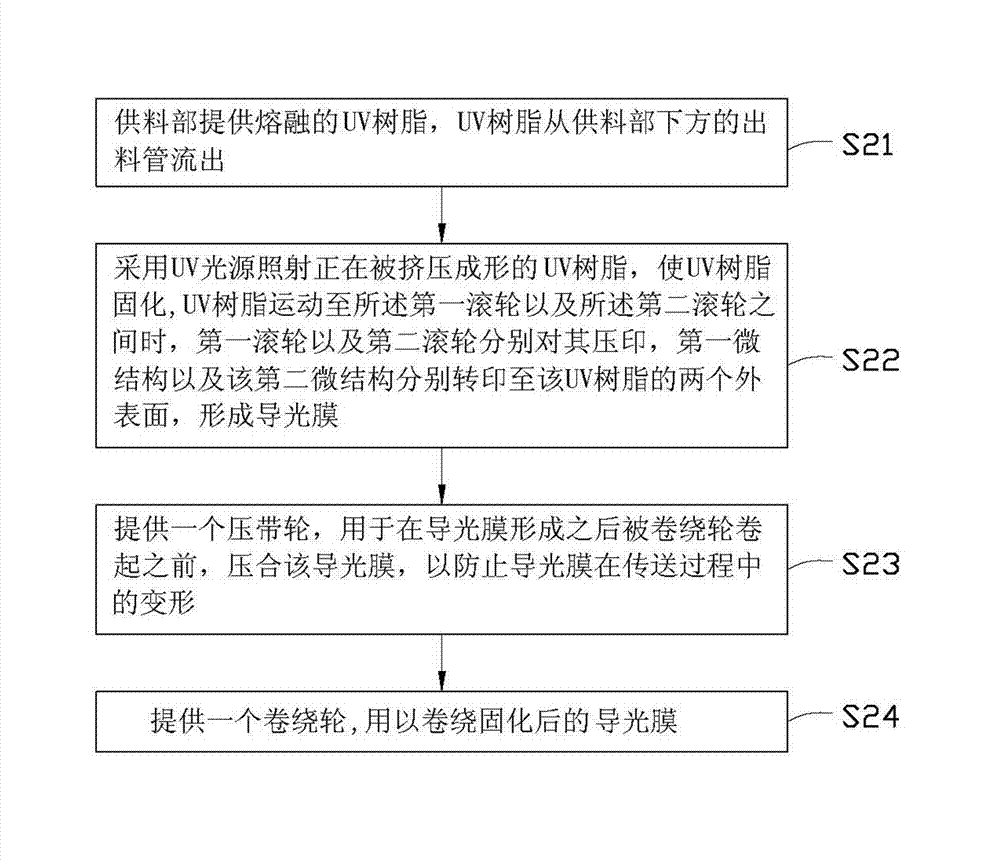

[0017] The present invention will be described in detail below in conjunction with the drawings.

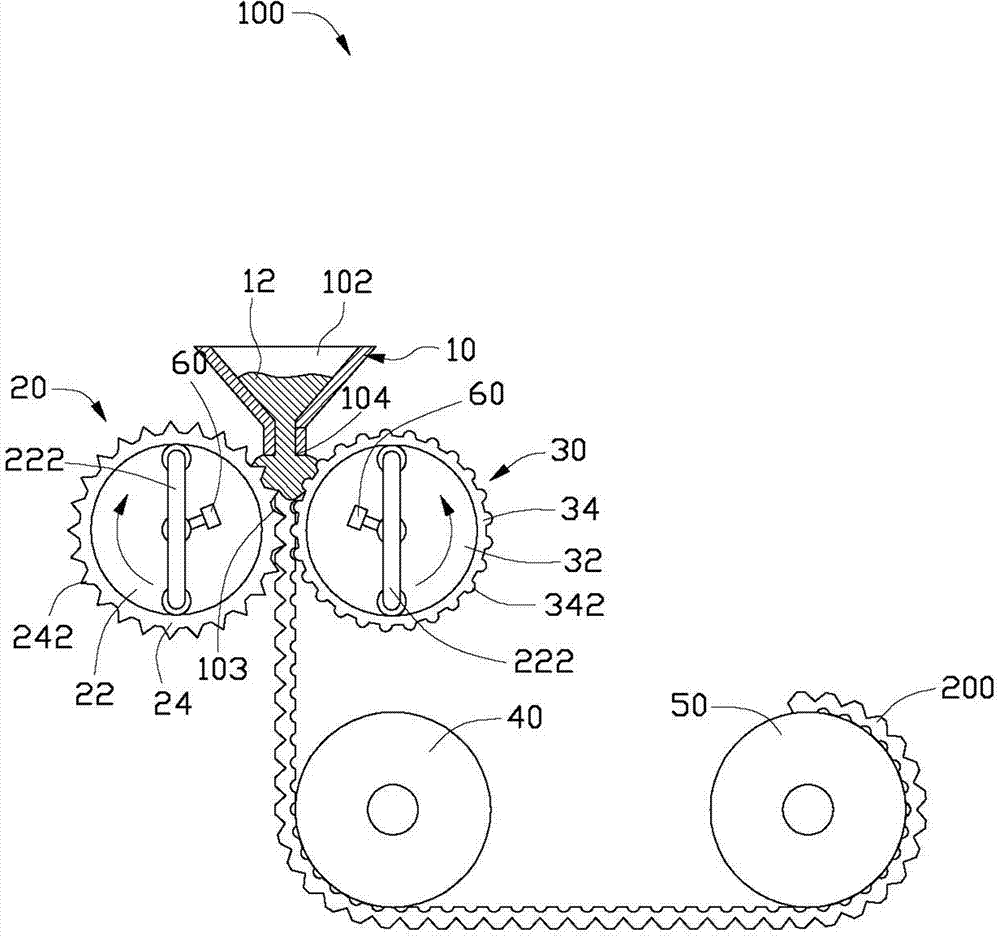

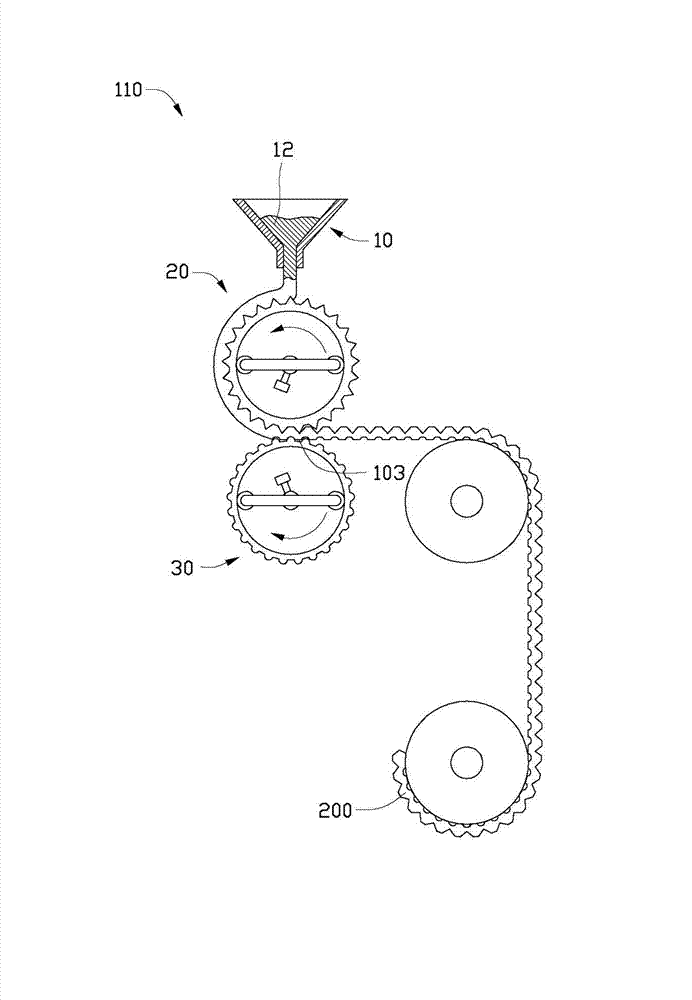

[0018] See figure 1 , Shown is a schematic diagram of the light guide film manufacturing apparatus 100 according to the first embodiment of the present invention. The light guide film manufacturing apparatus 100 includes a feeder 10 (here is a reciprocating coating head, in other embodiments it can be Scraper), a first roller 20, a second roller 30, a pinch roller 40 and a winding wheel 50.

[0019] The feeding part 10 is used to supply the raw material for manufacturing the light guide film 200. In this embodiment, the raw material of the light guide film 200 is the UV resin 12 in a molten state. The feeding part 10 is roughly in the shape of a funnel, which includes a feeding port 102 and a corresponding discharging tube 104. The UV resin 12 enters the feeding part 10 from the feeding port 102 and flows out along the discharging tube 104.

[0020] The first roller 20 and the second r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com