Air-flowing type dynamic liquid-phase micro-extracting method for online derivatization

A gas-flow, derivatization technology, applied in the preparation of test samples, etc., can solve the problems of adding derivatization steps of extracts, adverse effects of chromatographic columns, and unsatisfactory analysis results, and achieves the effect of simple operation and easy combination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

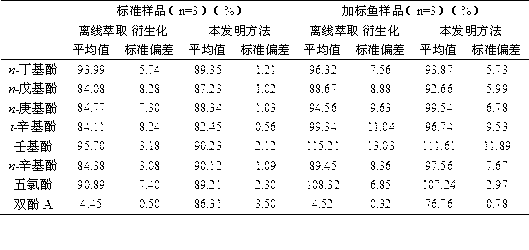

Examples

Embodiment Construction

[0019] The specific implementation process is as follows: ① Inert gas 2 is introduced into the sample cell 1 at a certain airflow rate; ② Under the condition of a certain sample cell temperature of 150-300oC, the substance 3 to be measured in the sample matrix is quickly desorbed into the gas phase to form a gaseous The substance to be tested is 4; ③ at the same time, the derivatization reagent 5 is continuously introduced into the sample pool 1, and the derivatization reagent 5 can be selected from silylating reagents, alkylating reagents or acetylating reagents that can react under high temperature and solvent-free conditions , such as trimethylsilane reagent, and vaporize at the sample phase temperature to become the gasified derivatization reagent 6; ④ Under the sample phase temperature condition, the gaseous analyte 4 and the gasified derivatization reagent 6 rapidly The reaction generates the derivatization product 7 of the gaseous substance to be tested; ⑤ driven by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com