Method for controlling diffusion and migration of underground gasification residual pollutants

A technology for underground gasification and pollutants, applied in coal gasification, underground mining, filling, etc., can solve problems such as difficult hydrolysis acidification operations, low price of hydrogen peroxide, and increased cost of underground gasification wastewater, and achieve good interception and adsorption capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

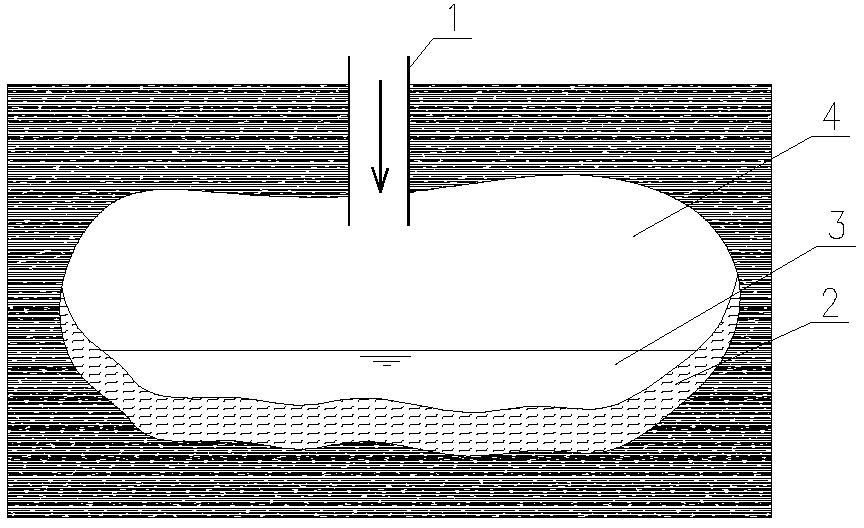

[0038] An embodiment of a method for controlling the diffusion and migration of residual pollutants from underground gasification. In this embodiment, three functional layers are set up to prevent harmful substances in underground gasification pollution areas from further migrating to underground water systems and expanding re-pollution. function, and can prevent external clean water from flowing into the polluted area and then being polluted.

[0039] These three functional layers include an anti-seepage layer made of bentonite at the bottom, a waterproof layer made of waterproof material at the top, and a supporting layer in the middle.

[0040] The bottom layer is composed of bentonite, which can trap pollutants in wastewater and prevent them from migrating to groundwater. The waterproof layer set on the top layer can isolate the external clean water source from contact with the gasification wastewater pollution area, preventing the clean water source from moving in and bei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com