A surface treatment method for preventing rubber products from blooming

A rubber product and surface treatment technology, which is applied in the field of rubber product production, can solve problems such as uncoating, tarnishing of the product surface, and additional process steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Natural rubber gloves cured from the natural rubber gloves, intercepted 4 fingers on this glove, and 4 fingertips surfaces were rinsed with 95% ethanol scrubbing and purge. The A171 (vinyltrimethoxysilane) solution having a concentration of 1 wt% (the solvent is alcohol: water volume = 5: 5), the formulation concentration is 0.01% by weight, 0.05 wt%, 0.1% by weight of three different specifications of oxidation The graphene suspension is 150 ml. The oxide oxide in the three specification of the oxide inkylene suspension is produced from the same batch of Hummer's Method.

[0049] Four fingers were impregnated with tweezers to 4-5 s in the A171 solution, and were dried in an oven at 60 ° C. After drying, then three finger sleeve clamping and turned to the concentration of 0.01% by weight, 0.05 wt%, 0.1 wt% three specification, and completely impregnated 4- After 5S, it was taken out, and the observation was taken in an oven at 100 ° C.

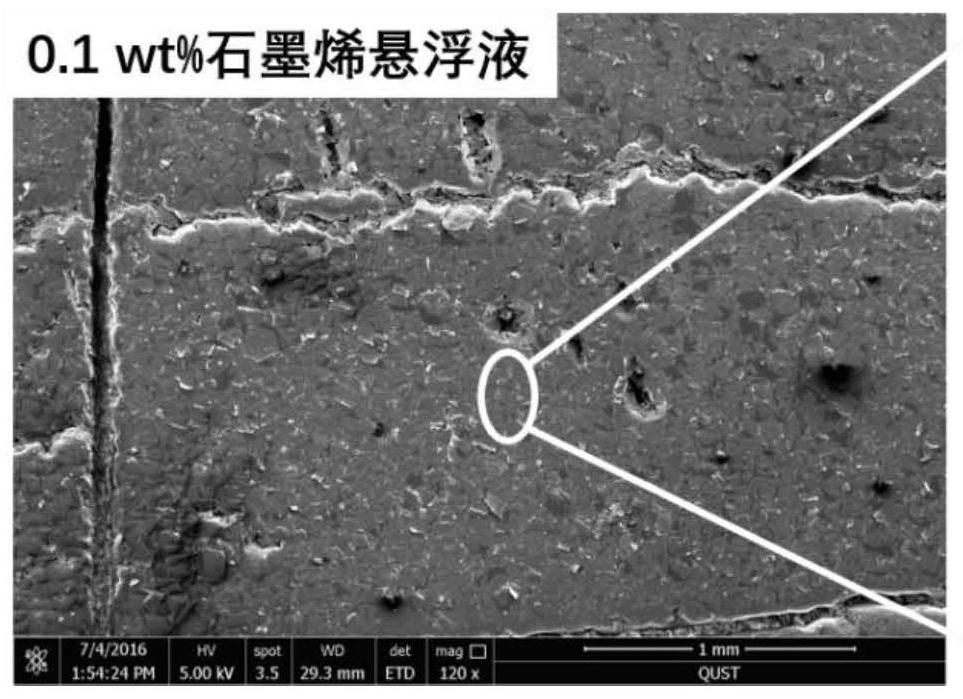

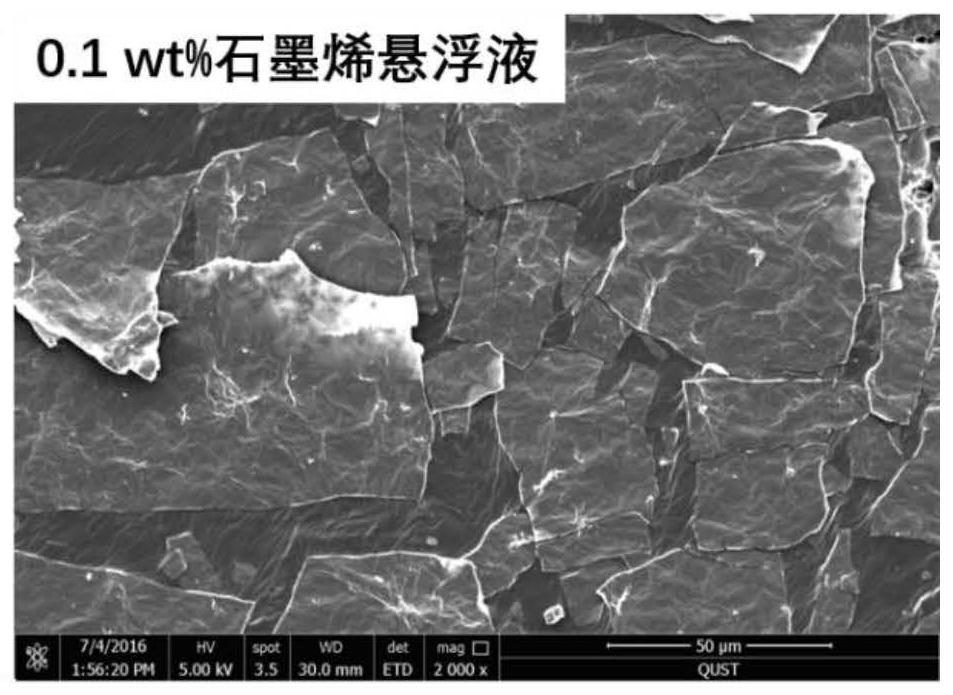

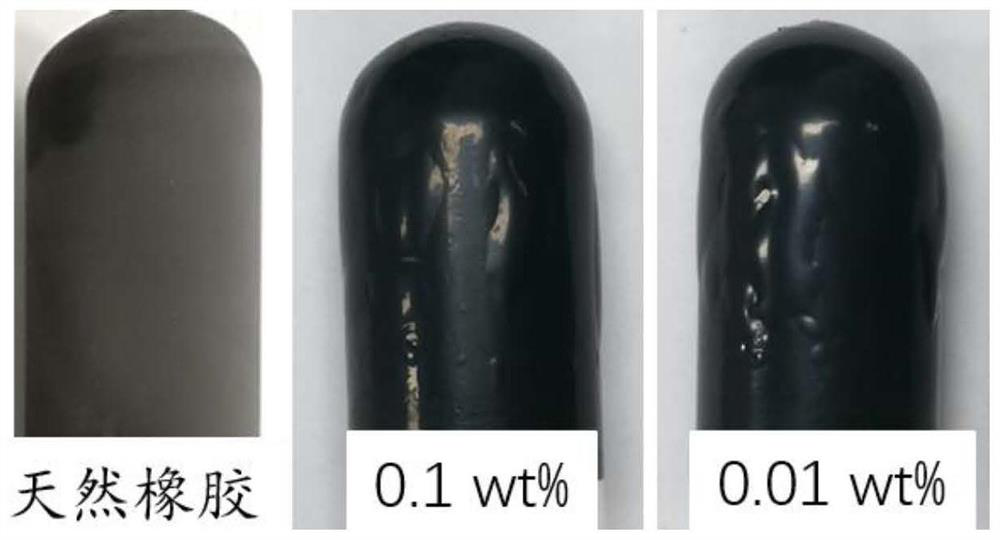

[0050] Such as figure 1 As shown, th...

Embodiment 2

[0054] A natural rubber glove of a rubber glove was taken from the natural rubber gloves, and one finger sleeve was intercepted on the glove, and the surface of 1 finger sleeve was washed with 95% ethanol and washed.

[0055] The A151 (vinyl triethoxysilane) solution having a concentration of 1.5 wt% was formulated (the solvent was alcohol: water volume = 5: 5), and the concentration of 0.1% by weight of the oxide in graphene suspension was formulated 150 ml. Among them, oxidized graphene is from the Hummer's method.

[0056] The intercepted finger sleeve was immersed in a 151 solution to the A151 solution, and then dried in an oven at 60 ° C. After drying, remove the finger sleeve and turn the fingertips to the oxide oxide in the concentration of 0.1% by weight, and then removed from the oxide of 120 ° C and dried in an oven at 120 ° C. ,take out. After stirring in 200 ml of deionized water, it was repeated 3 times, and then dried at 100 ° C.

[0057] Place this finger in electro...

Embodiment 3

[0059] A natural rubber glove of the natural rubber gloves is taken from the natural rubber gloves (adding black color paste, making color for pure black gloves), intercepted three fingers on this glove, 3 finger sets 95% ethanol washed and rinsed after the surface was flushed.

[0060] The A171 (vinyltrimethoxysilane) solution having a concentration of 2 wt% (the solvent is alcohol: water volume = 5: 5), the formulated concentration of 0.01% by weight, 0.1% by weight of two specifications of the oxide inkylene suspension 200ml. The oxide oxide in the oxide insertioned oxide in the oxide inkylene is prepared from the same batch of Hummer's method.

[0061] Three fingers were extracted from 4-5 s of the A171 solution to the A171 solution, and then dried in an oven at 60 ° C. After drying, then two fingers were removed by nickerel, and then impregnated into the concentration of 0.01 wt%, 0.1% by weight, and then removed 4-5 s, place it together. Drying in an oven at 110 ° C and take...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com