Joint arrangement for an articulated shaft

A joint device and journal technology, which is applied in the field of joint devices, can solve problems such as high load and bearing failure, and achieve the effect of reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

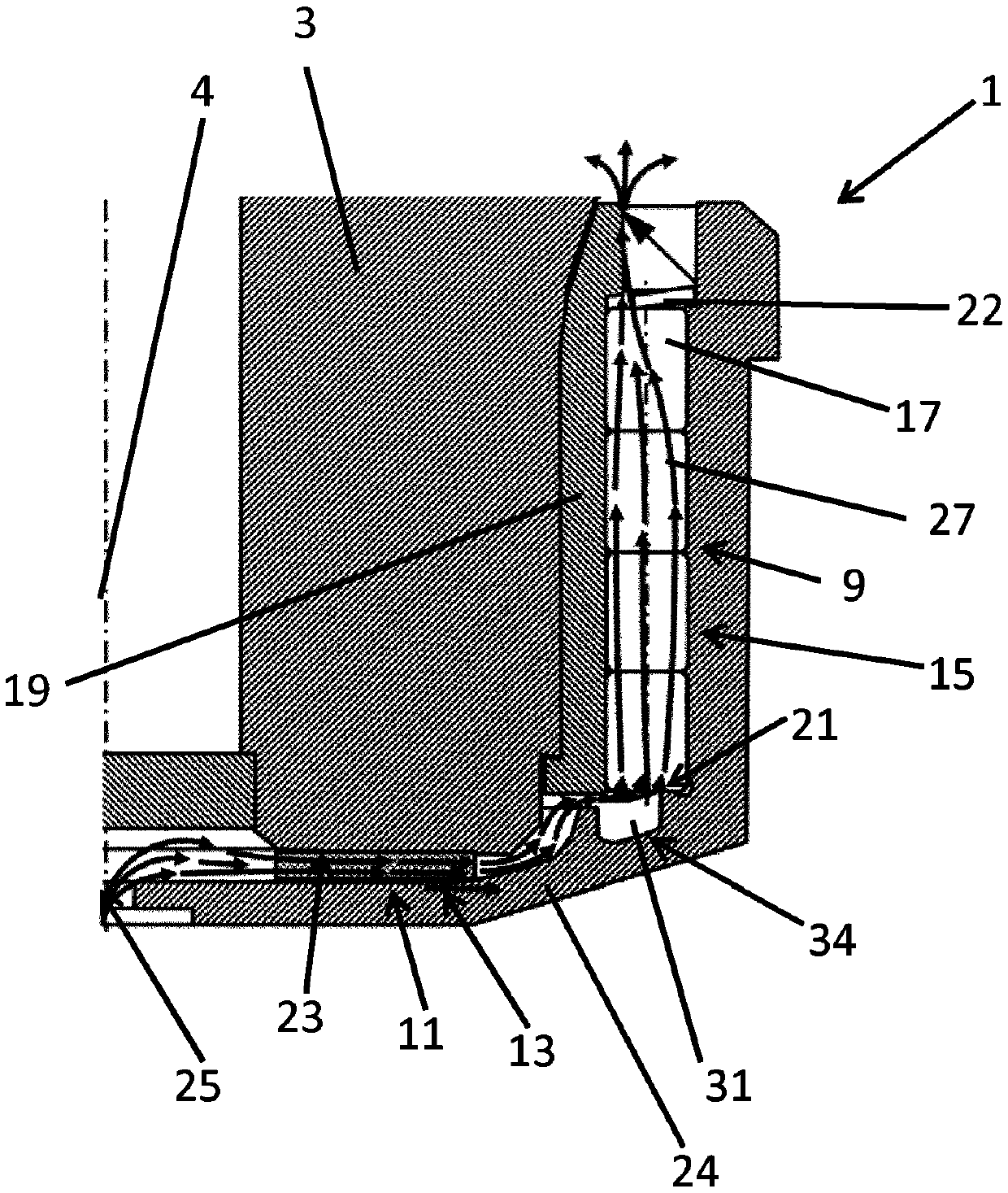

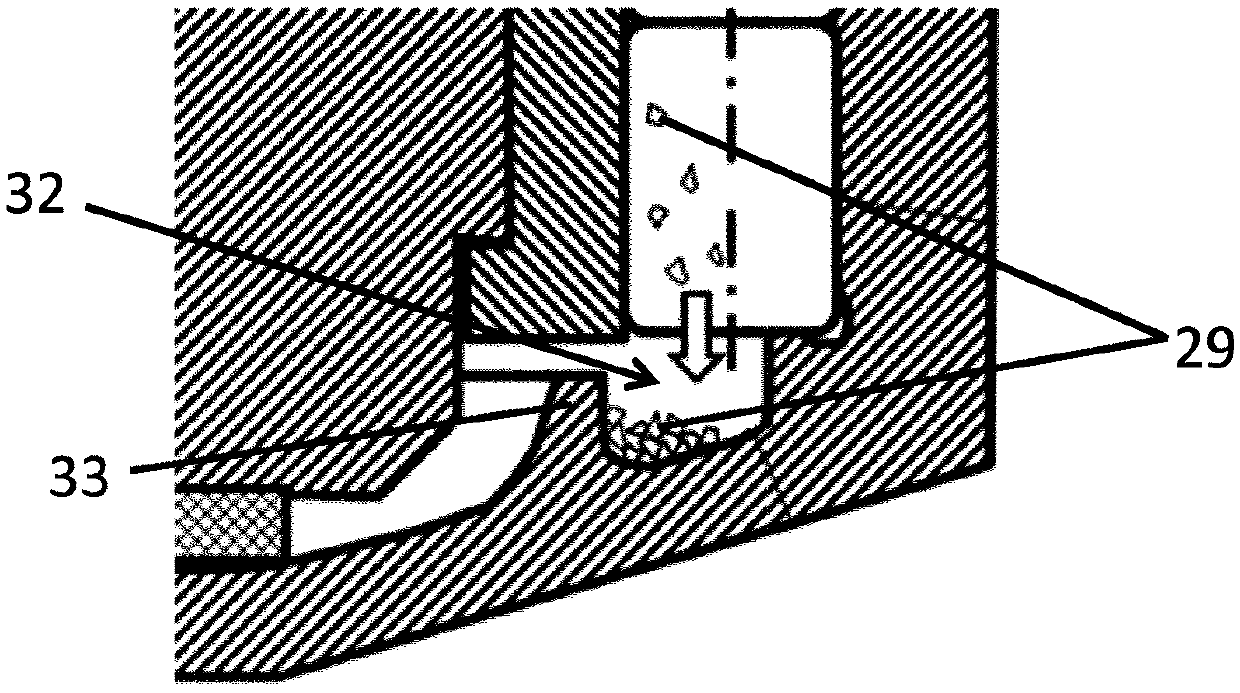

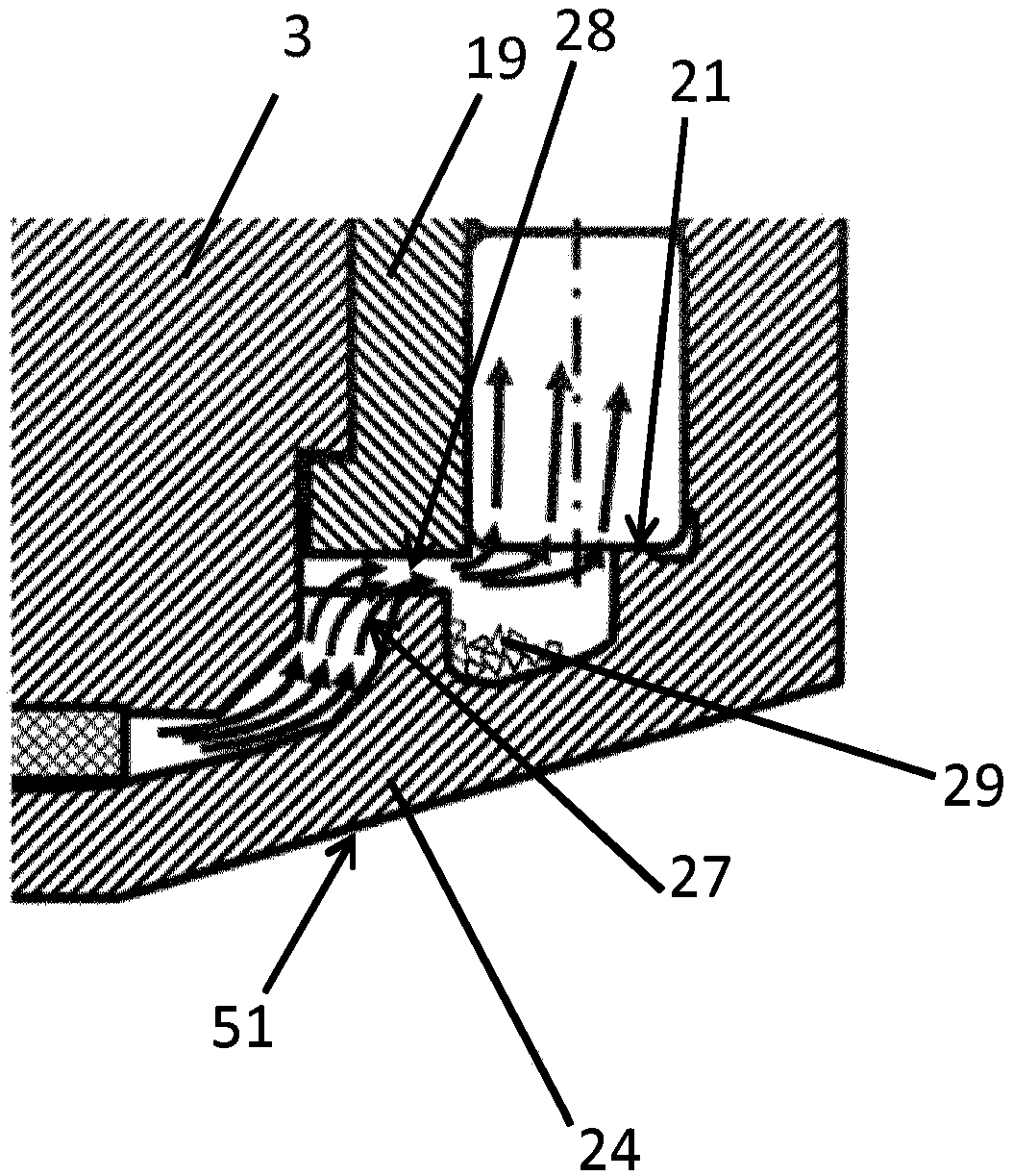

[0041] exist figure 1 The joint device 1 is shown in . The joint arrangement has a journal 3 with an axial axis 4 . Such as Figure 11 As shown in , a radial bearing 9 and an axial bearing 11 are provided for supporting the journal 3 in the joint fork 5 . In the exemplary embodiment shown, a rolling bearing 15 with rolling elements 17 is provided as radial bearing 9 . The rolling bodies 17 are supported by means of a bearing shell 19 in a cover 24 coaxially surrounding the journal 3 . The rolling element 17 is supported by a stop 21 formed on the cover 24 and cooperating with the spring element 22 . The journal 3 has a free end 23 . A slide bearing 13 is arranged as axial bearing 11 between the cover 24 and the free end of the journal 23 .

[0042] To lubricate the bearings 9 and 11 , lubricant is introduced through the lubricant opening 25 . The lubricant openings are generally formed in the cover 24 . Due to the movement of the joint arrangement 1 , the lubricant is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com