Dust suppressant and preparation method and dust suppression method thereof

A dust suppressant and sodium humate technology, applied in the field of environmental pollution control, can solve problems such as boiler aging, affecting coal combustion characteristics, and insufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] Therefore, the embodiment of the present invention discloses a kind of preparation method of dust suppressant, comprises the following steps:

[0025] Sodium humate is mixed with water to obtain a mixed solution;

[0026] The mixed solution is mixed with the acid solution to obtain the dust suppressant.

[0027] According to the present invention, the sodium humate can be directly purchased from the market, or can be obtained by reacting humic acid and sodium hydroxide, specifically:

[0028] Mix humic acid and water, stir evenly, heat and add sodium hydroxide, then raise the temperature to 90-100°C and keep it warm for 100-140min to obtain sodium humate.

[0029] The above-mentioned humic acid itself is insoluble in water, so it needs to be sodiumized first to make it into a water-soluble sodium salt, sodium humate. Well known to those skilled in the art, the humic acid is derived from lignite, so the sodium humate can also be obtained by reacting lignite with sodium...

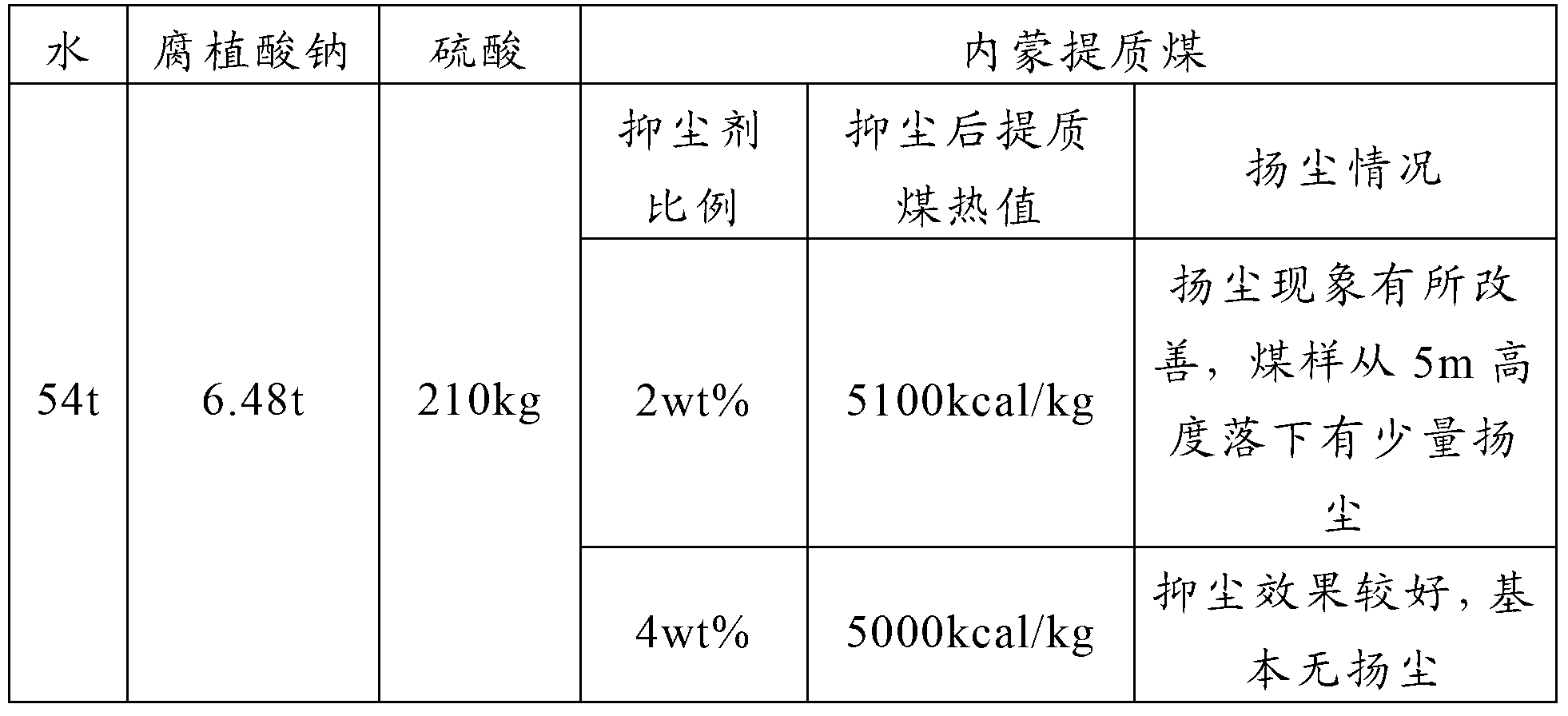

Embodiment 1

[0039] Prepare sodium humate solution with 54t of water and 6.48t of sodium humate;

[0040] Add sulfuric acid with a concentration of 98wt% to the above sodium humate solution until the pH value is neutral to obtain a dust suppressant.

Embodiment 2

[0042] Weigh 540kg of water and 64.8kg of humic acid (this is the dry weight of humic acid, the weight of humic acid is 89.8kg, of which the water content is 27.84wt%), and 8kg of sodium hydroxide;

[0043] Put the above-mentioned humic acid and water into the reaction kettle, stir evenly to obtain a mixed solution, heat the mixed solution and slowly add 8kg of sodium hydroxide;

[0044] When the temperature of the reaction kettle rose to 95°C, it was kept warm for 120 minutes, then the heating was stopped, and then hydrochloric acid with a concentration of 36wt% was slowly added dropwise until the pH value was neutral to obtain a dust suppressant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com