Method for preparing vinyl-functionalized white carbon black for reinforcing methyl vinyl silicone rubber

A technology of methyl vinyl silicon and vinyl functions, which is applied in the field of preparation of vinyl functionalized silica for reinforcement of methyl vinyl silicone rubber, which can solve the problem of poor stability of the adsorption transition layer, affecting product performance, and stress relaxation To improve the reinforcement effect, reduce the number of hydroxyl groups, and improve the hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A preparation method of vinyl functionalized white carbon black for methyl vinyl silicone rubber reinforcement, the preparation steps are: tetraethyl orthosilicate: catalyst ammonia water: solvent absolute ethanol: modifier undecenyl alcohol is 6 : The volume ratio of 3:1:1, mixed ethyl orthosilicate, catalyst ammonia water (0.75mol / L), solvent absolute ethanol and modifier undecenyl alcohol, reacted at 65°C for 1.5h, and then Filtration, the solid obtained after filtration is washed with absolute ethanol as a solvent for 3 times, and then dried to obtain a vinyl functionalized white carbon black product.

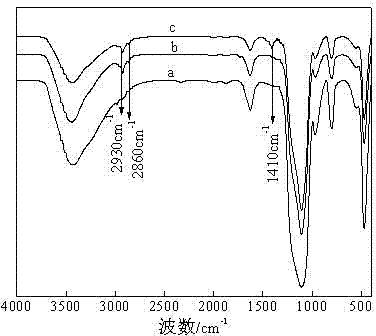

[0020] attached figure 1 It is the infrared spectrogram of the vinyl-functionalized silica prepared in this example; in the figure, -CH2 and -CH2 and - The characteristic peak of CH3, the characteristic peak of ethylene end group = CH2 appeared at the wave number of 1410cm-1; the infrared results confirmed that the vinyl group of undecylenol was successfully grafted...

Embodiment 2

[0022] Adopt torque rheometer to prepare mixed rubber, the preparation process is as follows: add methyl vinyl silicone rubber, the vinyl functionalized white carbon black that embodiment 1 makes and hydroxyl silicone oil and mix by the mass ratio of 100:40:8 Mixed uniformly in a container to prepare the mixed rubber I, the mixing temperature was 105°C, the rotational speed was 90 r / min, and the time was 30 min; Mix uniformly in the mill to prepare mixed rubber II, and test the vulcanized storage modulus; use a flat vulcanizer to prepare vulcanized rubber. The preparation process is as follows: the mixed rubber II is vulcanized on a plate at 120°C to obtain a vulcanized rubber sheet, which is then cut. sample test.

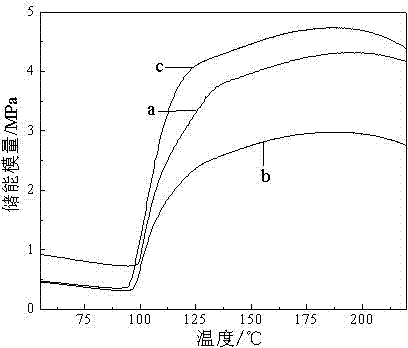

[0023] attached figure 2 It is the vulcanization temperature scanning storage modulus test chart of the mixed rubber II of Example 2; in the figure, compared with the unmodified silica and the undecyl alcohol modified silica, the vinyl functionalized silica It ...

Embodiment 3

[0028] A preparation method of vinyl functionalized white carbon black for methyl vinyl silicone rubber reinforcement, the preparation steps are: tetraethyl orthosilicate: catalyst ammonia water: solvent absolute ethanol: modifier undecenyl alcohol is 6 : 3:1:1 volume ratio, mix ethyl orthosilicate, catalyst ammonia water, solvent absolute ethanol and modifier undecylenol evenly, react at 50°C for 2h, and then filter, the solid obtained after filtration The product was washed twice with absolute ethanol as a solvent, and then dried to obtain a vinyl-functionalized white carbon black product.

[0029] Others are the same as embodiment 1 and embodiment 2, omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com