Hexagonal ferrite material with high magnetic loss in L wave band and preparation method thereof

A hexagonal ferrite, L-band technology, applied in the field of materials, can solve the problems of mismatch between wave-absorbing coating and free space impedance, inability to absorb electromagnetic waves well, poor magnetic loss performance, etc., and achieve excellent high-frequency soft magnetic properties high performance, easy mass production, and high magnetic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method comprises the following steps:

[0029] 1. Mixed raw materials: the main components and content (mass percentage) of the present invention are calculated as: BaCO 3 : 0.00~23.55wt%, SrCO 3 :0.00~18.75wt%, CoO: 6.68~7.09wt%, Fe 2 o 3 : 69.76~74.15wt%.

[0030] Weigh the raw materials as required, and put them into a ball mill for ball milling. The mass ratio of the ball milled material, zirconia balls, and deionized water is 1:3:1.2, and the mass ratio of large-sized balls (radius about 4.4mm) and small-sized balls (radius about 2.5mm) is 1: 2. The ball milling time is 3 hours, and the rotation speed is set at 300 revolutions per minute. The main purpose of ball milling is to mix raw materials evenly.

[0031] 2. Pre-burning: Dry the ball-milled raw materials, put the dried raw materials into a high-temperature furnace under air or oxygen atmosphere for pre-burning, the pre-burning temperature is 1120-1220 °C, and the heating rate is 3 °C per...

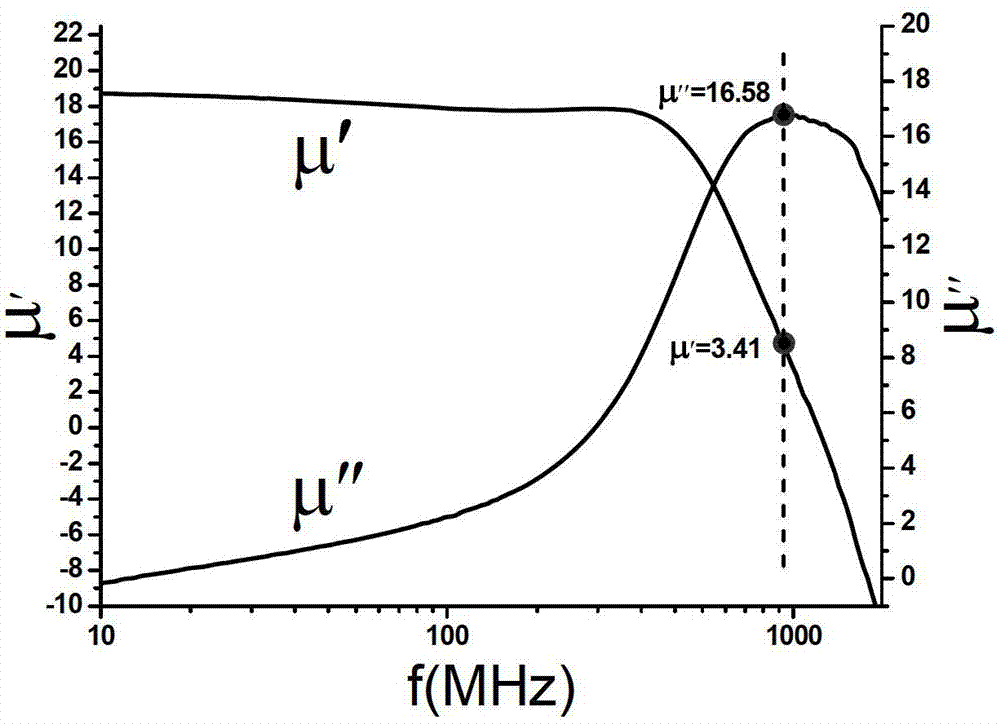

Embodiment 1

[0034] 1. The main components and content (mass percentage) are calculated as oxides:

[0035] Formulation: BaCO 3 : 23.56wt%, SrCO 3 : 0.00wt%, CoO: 6.67wt%, Fe 2 o 3 : 69.76wt%, that is, the chemical composition is: (Ba 1-x Sr x ) 3 co 2 Fe 24 o 41 , where x=0.0.

[0036]2. Mixing and ball milling raw materials: weigh the raw materials according to the requirements, and put them into a ball mill for ball milling. The mass ratio of the ball milled material, zirconia balls, and deionized water is 1:3:1.2, and the mass ratio of large-sized balls (radius about 4.4mm) and small-sized balls (radius about 2.5mm) is 1: 2. The ball milling time is 3 hours, and the rotation speed is set at 300 revolutions per minute. The main purpose of ball milling is to mix raw materials evenly.

[0037] 3. Pre-burning: After drying the ball-milled raw materials, put them into a high-temperature furnace under air atmosphere for pre-burning. The pre-burning temperature is 1170°C, the heat...

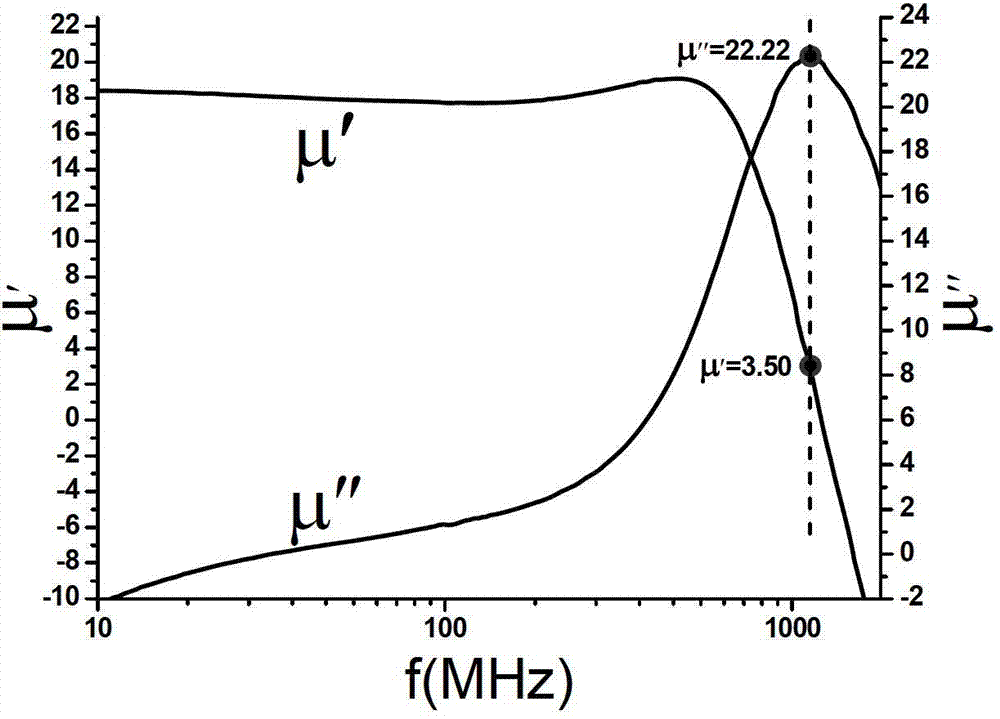

Embodiment 2

[0041] 1. The main components and content (mass percentage) are calculated as oxides:

[0042] Formulation: BaCO 3 : 19.08wt%, SrCO 3 : 3.57wt%, CoO: 6.76wt%, Fe 2 o 3 : 70.59wt%, that is, the chemical composition is: (Ba 1-x Sr x ) 3 co 2 Fe 24 o 41 , where x=0.2.

[0043] 2. Mixing and ball milling raw materials: weigh the raw materials according to the requirements, and put them into a ball mill for ball milling. The mass ratio of the ball milled material, zirconia balls, and deionized water is 1:3:1.2, and the mass ratio of large-sized balls (radius about 4.4mm) and small-sized balls (radius about 2.5mm) is 1: 2. The ball milling time is 3 hours, and the rotation speed is set at 300 revolutions per minute. The main purpose of ball milling is to mix raw materials evenly.

[0044] 3. Pre-burning: Dry the ball-milled raw materials, put the dried raw materials into a high-temperature furnace under an air atmosphere for pre-burning, the pre-burning temperature is 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com