Parallel-central-valve type automobile brake master cylinder

A technology of automobile brake and master cylinder, which is applied in the direction of hydraulic brake transmission device, etc., can solve the problems of shortening the axial distance of the brake master cylinder, not being able to fully realize independent work, and easy damage, etc., to shorten the stroke of the brake push rod , Shorten the braking reaction time, the effect of quick response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The invention will be described in detail below in conjunction with the accompanying drawings.

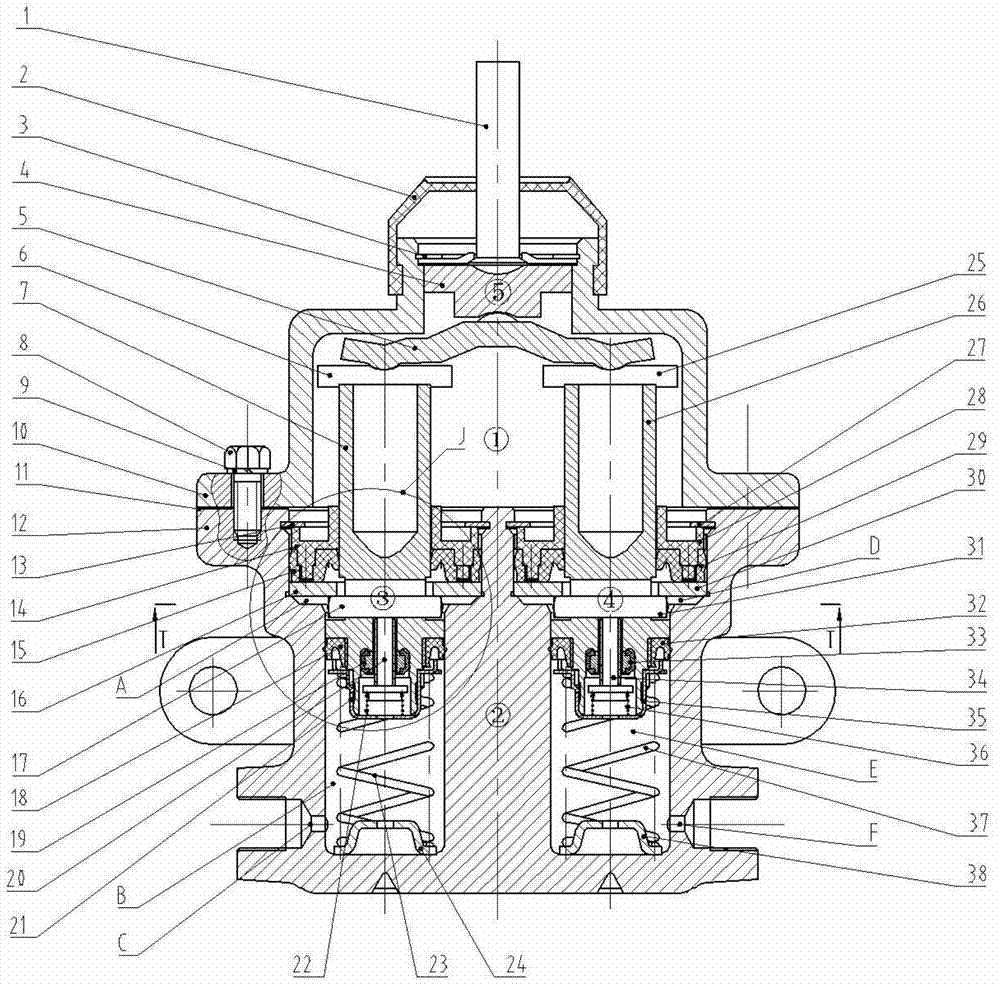

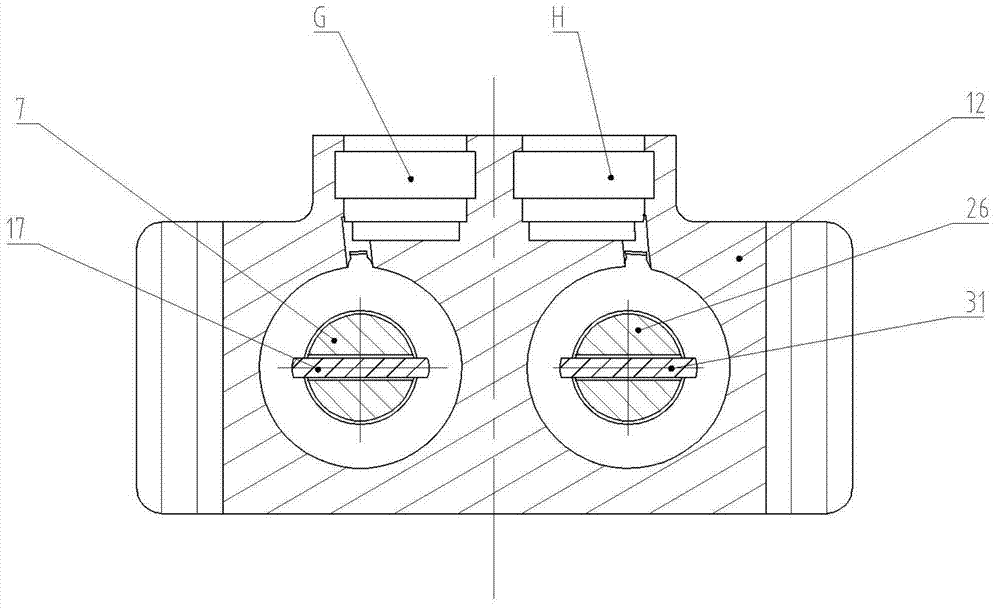

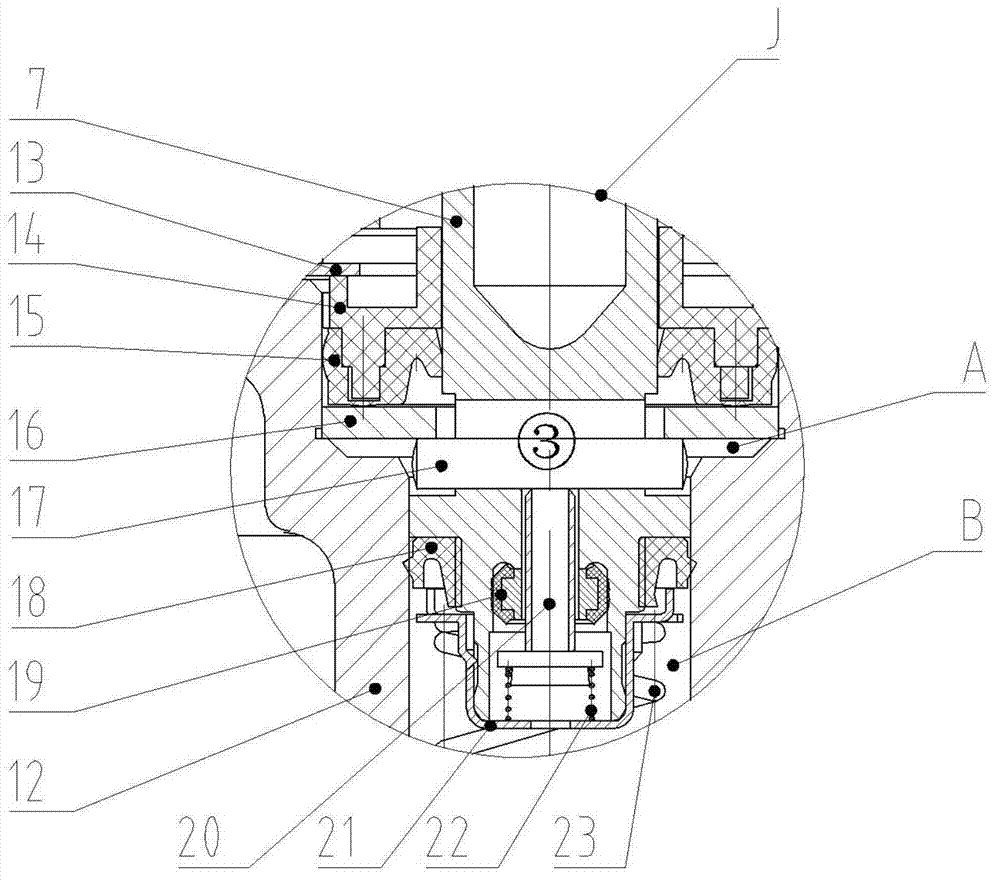

[0056] figure 1 It is the main cross-sectional view of the present invention, and it can be seen that a parallel central valve type automobile brake master cylinder of the present invention comprises cylinder upper part ①, cylinder body bottom ②, left master cylinder ③, right master cylinder ④ and force transmission mechanism ⑤, wherein , the force transmission mechanism ⑤ is located in the upper part of the cylinder body ①, and the thrust from the push rod and vacuum booster is transmitted to the left and right master cylinders ③ and ④ paralleled by the push rod 1 through the push rod 1; the left master cylinder ③ and the right master cylinder ④Located in the lower part of the cylinder body ②, it converts and amplifies the mechanical thrust transmitted by the push rod 1 into hydraulic pressure, and then transmits it to each wheel cylinder and wheel brake through the oil out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com