Shuttle valve having two drives

A driver and shuttle valve technology, applied in the field of shuttle valves, can solve the problems that the isolation valve is not suitable for adjusting the flow, cannot accurately perform and adjust the rotational motion, and cannot accurately perform and adjust the translational motion, etc. Simple design, precise adjustment of the effect of the task

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

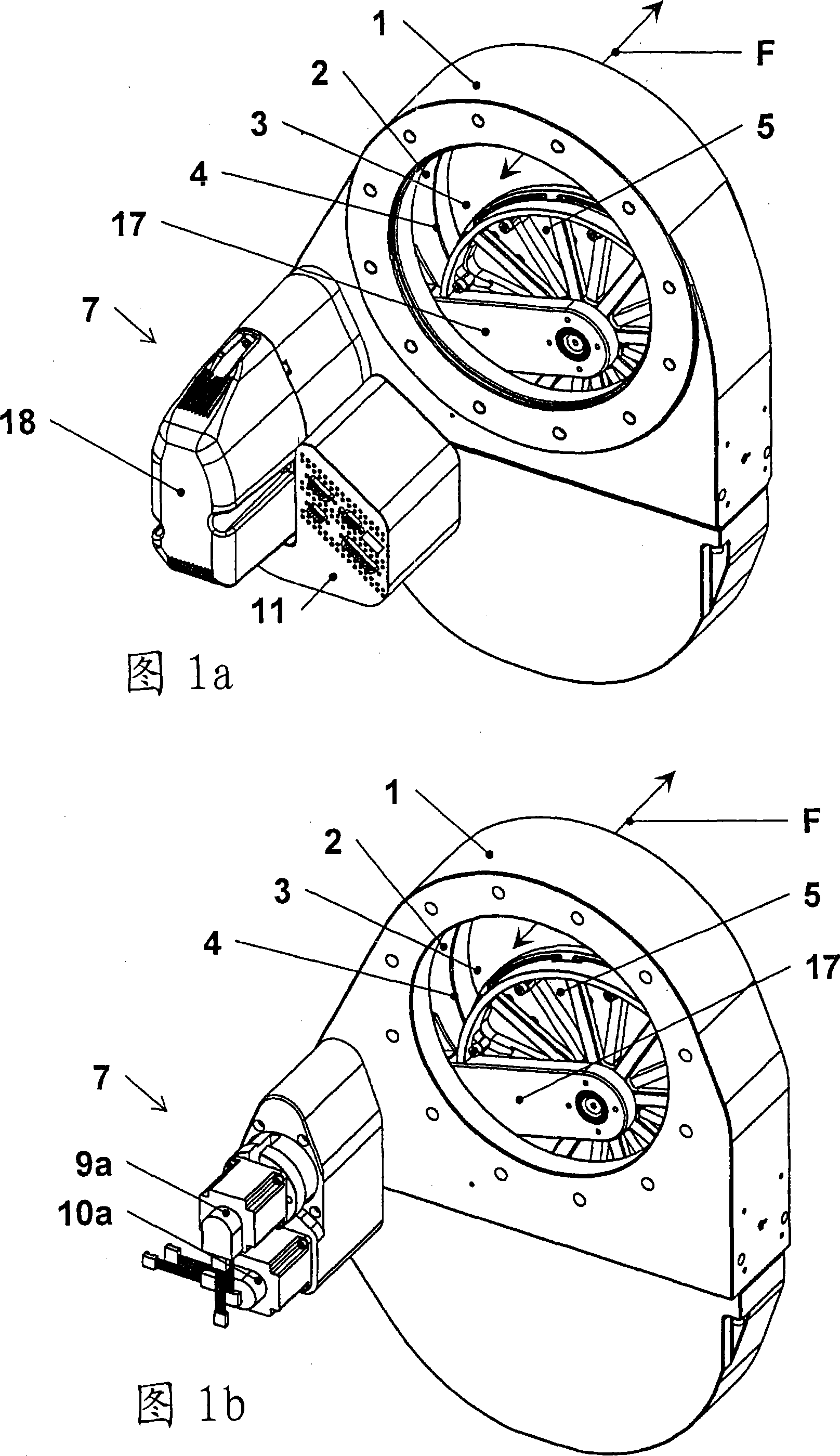

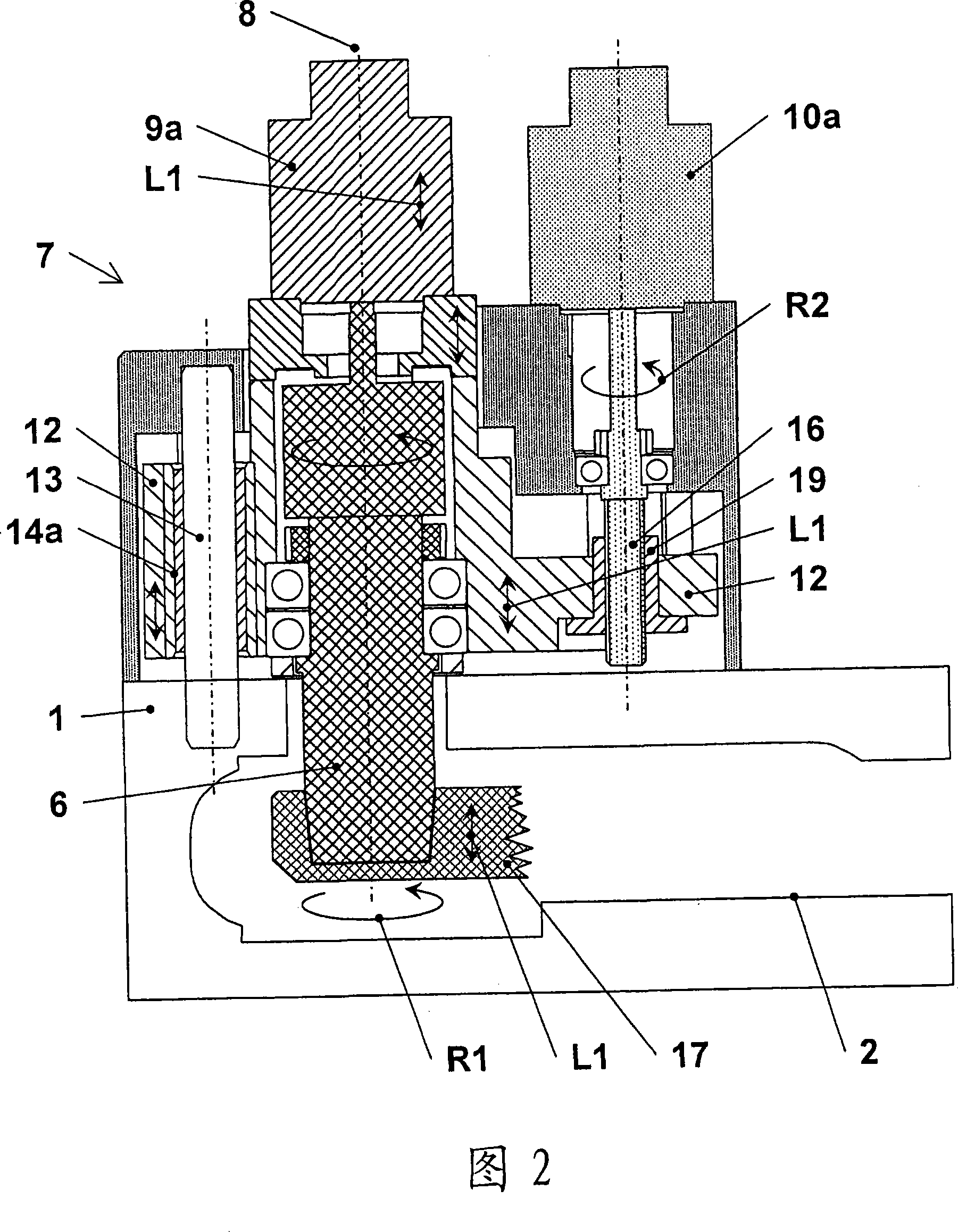

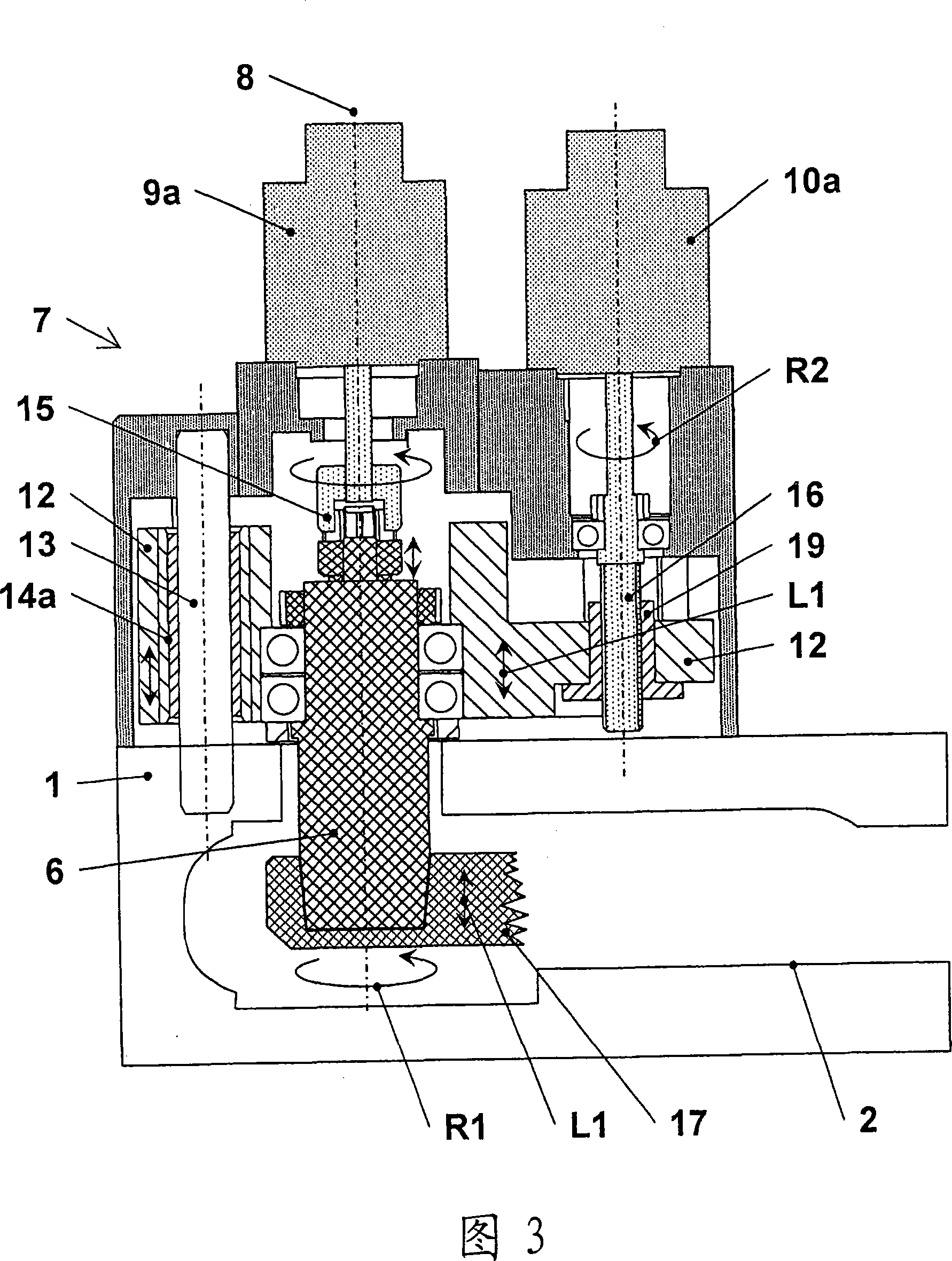

[0032] Figures 1a, 1b and 2 generally show an embodiment of the invention in different views, states and levels of detail, and these figures are therefore in some cases described together. Figures 2 to 6 each show an alternative embodiment of the drive unit. Since the figures in some cases use common reference numerals and the embodiments described in some cases have common features, reference numerals already explained above will partly be omitted.

[0033] Figures 1a and 1b show a shuttle valve comprising a valve housing 1 having a circular opening 3 in a wall 2 for a flow path F for a gas indicated by an arrow. The opening 3 is surrounded by a valve seat 4 formed by the edge portion of the wall 2 directed towards the interior of the valve housing 1 . Inside the valve housing 1 , a flat multi-part valve disc 5 is arranged pivotable on said opening 3 by means of an arm 17 . The shuttle valve has a drive unit 7 by means of which the valve disk 5 can be rotated on the opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com