Mechanical-solid phase composite connection device and connection method thereof

A solid-phase composite and connecting device technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low friction spot welding efficiency, reduce feed resistance, and speed up the process, so as to improve the connection efficiency, reduce The effect of riveting force and improving joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

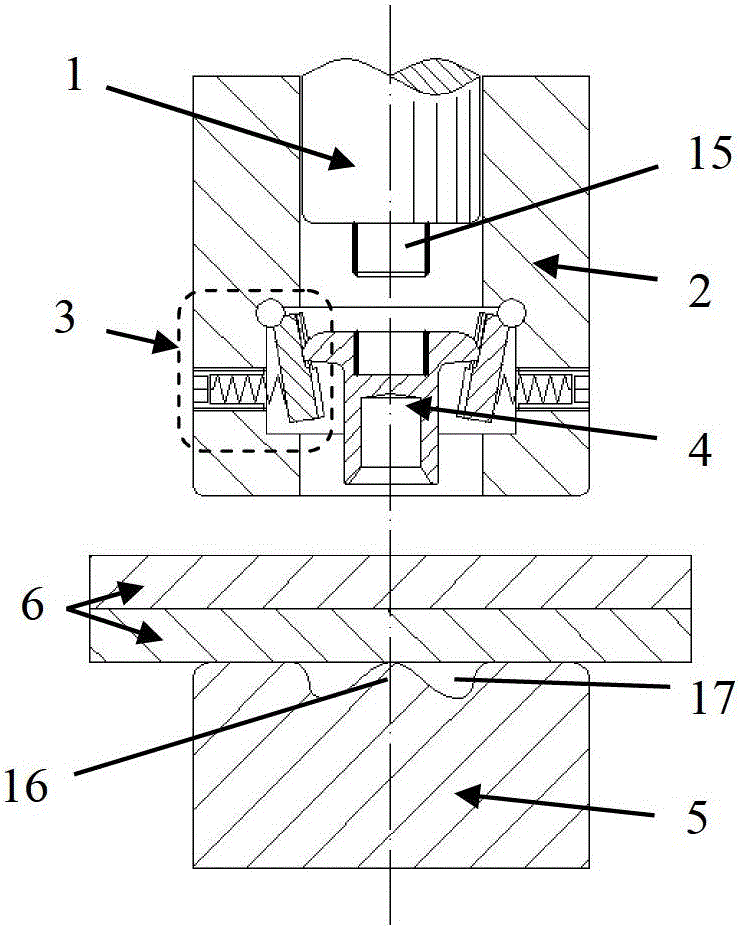

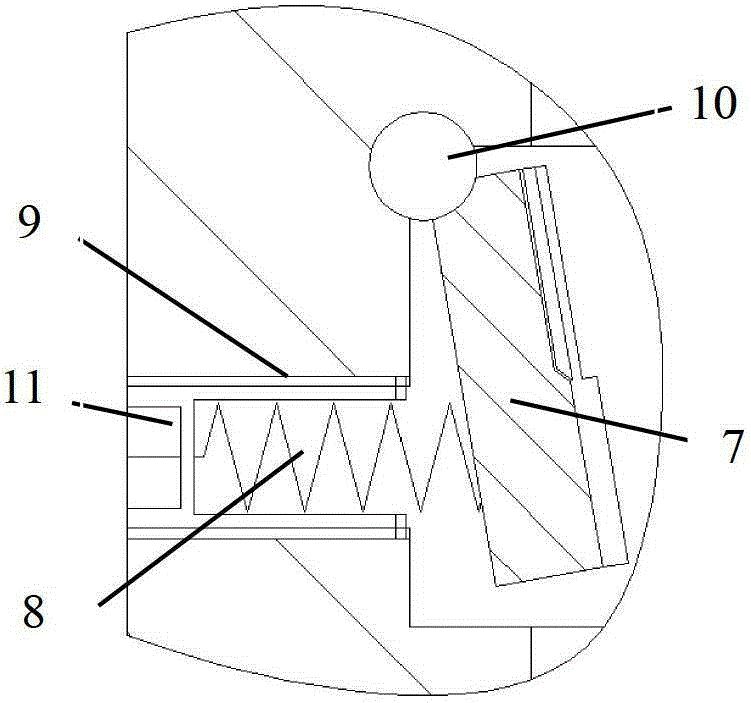

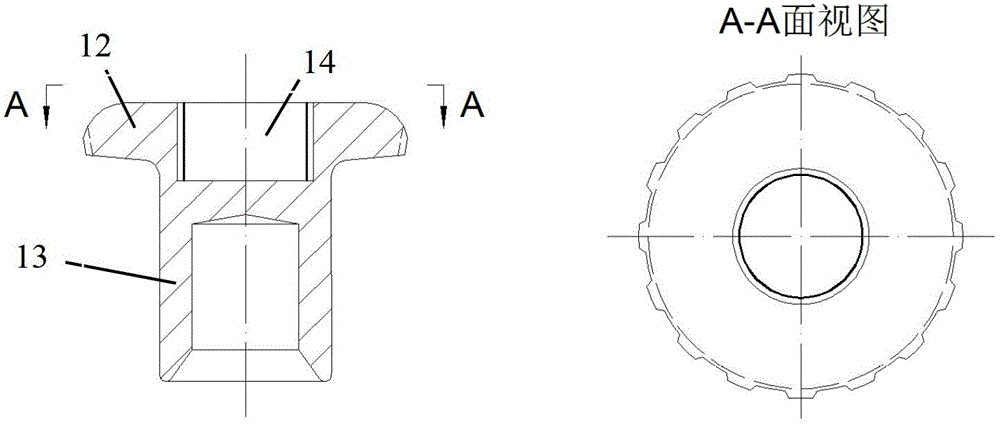

[0036] Such as figure 1As shown, this embodiment provides a mechanical-solid phase composite connection device, including: a driving pin 1, a blank holder ring 2, a number of spring disc positioning mechanisms 3, a semi-tubular rivet 4 and a die 5, wherein: a blank holder The ring 2 and the die 5 are arranged from top to bottom, and the plate 6 is arranged between the blank holder ring 2 and the die 5 . The driving needle 1 is sleeved in the blank holder 2, several spring disc positioning mechanisms 3 are radially and horizontally distributed in the blank holder 2, and the semi-hollow rivets 4 are vertically placed in the blank holder 2 and connected with the spring disc positioning mechanism 3-phase contact, driving pin 1, blank holder 2, semi-tubular rivet 4 and die 5 are arranged coaxially.

[0037] The inner diameter of the blank holder 2 is 10.4 mm, the outer diameter is 22.4 mm, and an annular groove with a width of 7.1 mm and a depth of 1.8 mm is provided inside it fro...

Embodiment 2

[0063] The plate 6 in this embodiment is: magnesium alloy AZ31+magnesium alloy AZ31; plate thickness matching: 2mm+2mm;

[0064] The process parameters of this embodiment: in the meshing stage, the rotation speed of the driving needle 1 is 60r / min, and the feed speed is 10mm / s; In the lock forming stage, the rotation speed of the driving needle 1 is 1600r / min, and the feed speed is 5mm / s; in the in-situ stirring stage, the rotation speed is maintained at 1600r / min for 60ms.

[0065] Other implementation modes of this embodiment are the same as Embodiment 1.

Embodiment 3

[0067] The plate 6 in this embodiment is: aluminum alloy AA6061-T6+carbon fiber composite material; plate thickness matching: 2mm+2mm;

[0068] The process parameters of this embodiment: in the meshing stage, the rotation speed of the driving needle 1 is 60r / min, and the feed speed is 10mm / s; In the lock forming stage, the rotation speed of the driving needle 1 is 1200r / min, and the feed speed is 5mm / s; there is no in-situ stirring stage.

[0069] Other implementation modes of this embodiment are the same as Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com