Slotting machine

A grooving machine and grooving technology, which is applied in the direction of metal processing machinery parts, clamping, support, etc., can solve the problems of not being able to meet the standards, difficult to ensure the processing depth of dovetail grooves, and affecting the pass rate of 220 products, so as to achieve low manufacturing cost , guaranteed depth and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

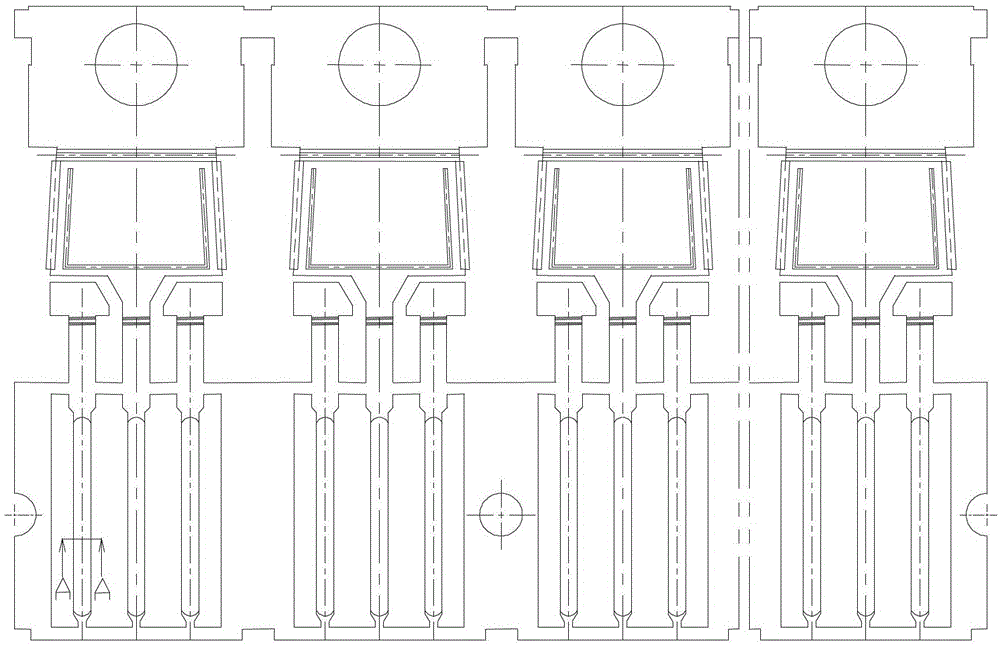

[0041] In order to provide a high-efficiency equipment that can guarantee the processing depth of the dovetail groove to a great extent and has low cost. This embodiment discloses a slotting machine, the main structure includes: a feeding mechanism, a guiding mechanism and a slotting mechanism. Specifically, the feeding mechanism is used to clamp the material belt and provide conveying power for the material belt; the guiding mechanism is used to guide the material belt conveyed by the feeding mechanism; the slotting mechanism is arranged at one end of the guiding mechanism for Groove the strip.

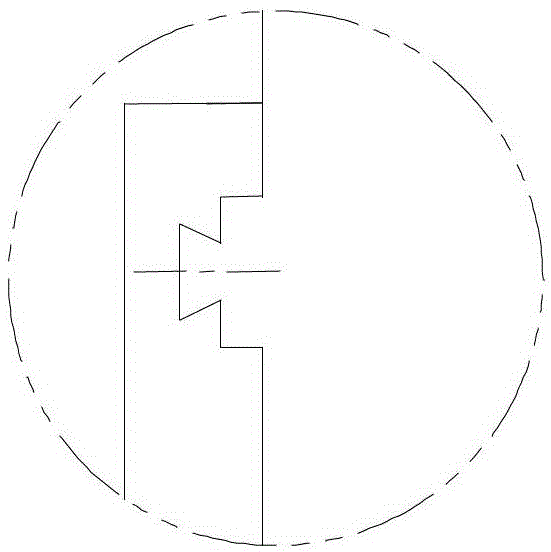

[0042] Figure 2a A schematic diagram of the front structure of a feeding mechanism according to an embodiment of the present invention is shown. Figure 2b A top structural schematic view of a feeding mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com