Iron-typed cast ball die

A mold and ball casting technology, applied in the field of iron mold casting ball mold, casting technology and equipment, and casting section production, can solve problems such as inability to suit mechanized operations, low productivity of a single pair of molds, product casting defects, etc., to avoid problems such as The effect of molten metal overflow, improving service life and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

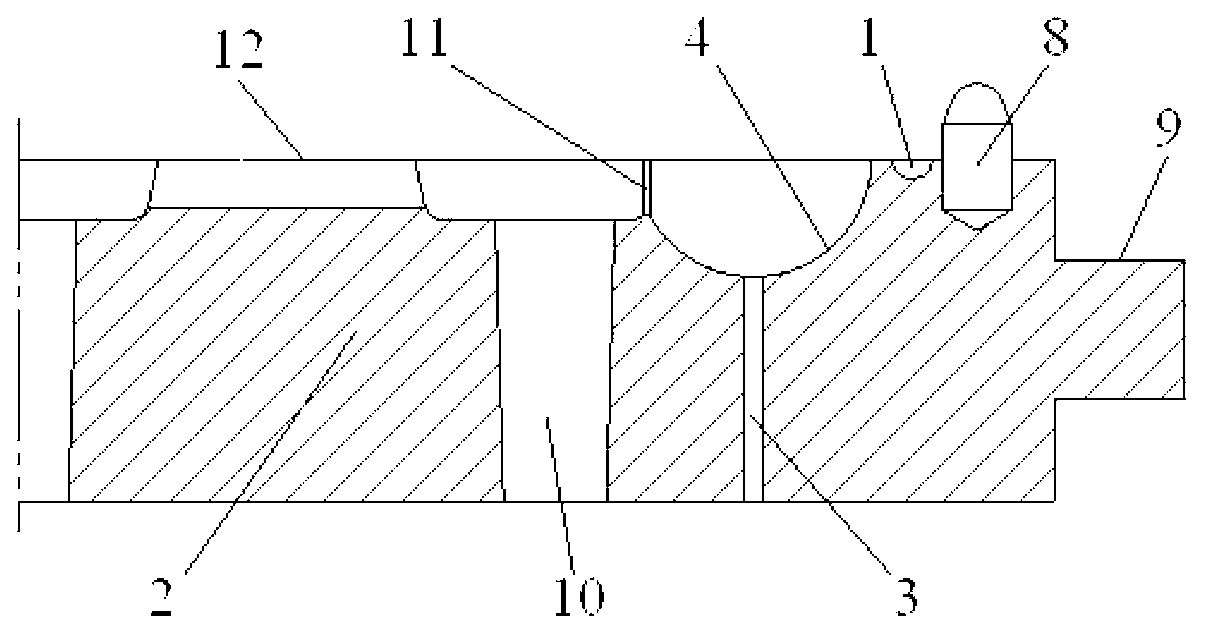

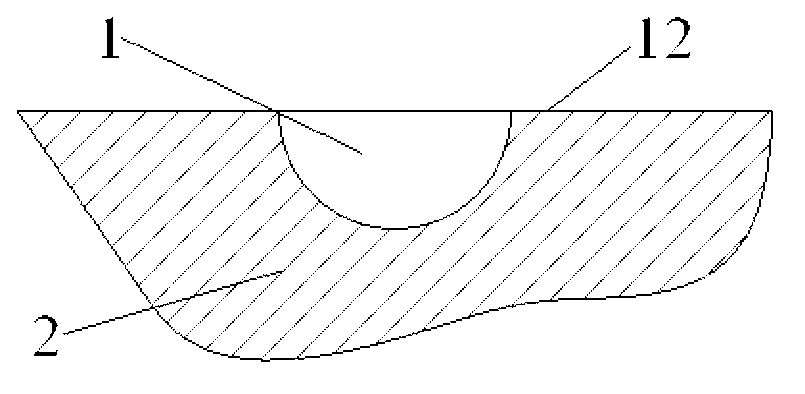

[0027] Such as Figure 1 to Figure 5 The structure of the present invention shown is an iron cast ball mold, which belongs to the technical field of metal material forming and processing, and relates to the technological equipment of casting and forming of wear-resistant material medium, especially related to the casting of wear-resistant cast balls or partial castings Production of metal molds.

[0028] The iron-type cast ball mold consists of an upper box and a lower box, the upper box and the lower box are two mold splits 2, and the joint surface of the two mold splits 2 forms a mold parting surface 12, The mold cavity 4 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com