Automatic processing equipment for squids

An automatic processing and squid technology, which is applied in the processing of cephalopods, fish processing, metal processing, etc., can solve the problems of non-uniform processing of squid, decline in product quality, and reduction in operating efficiency, and reduce the failure rate. The effect of improving uniformity and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

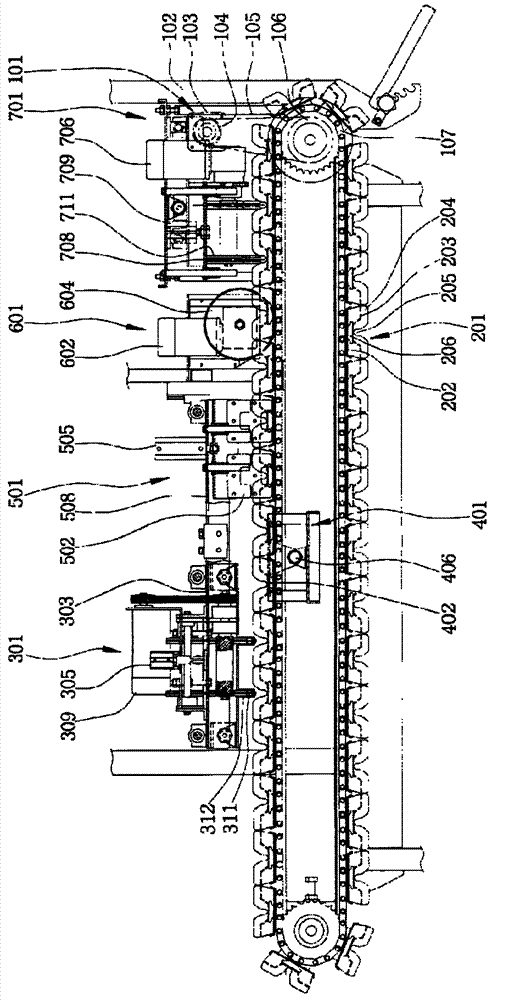

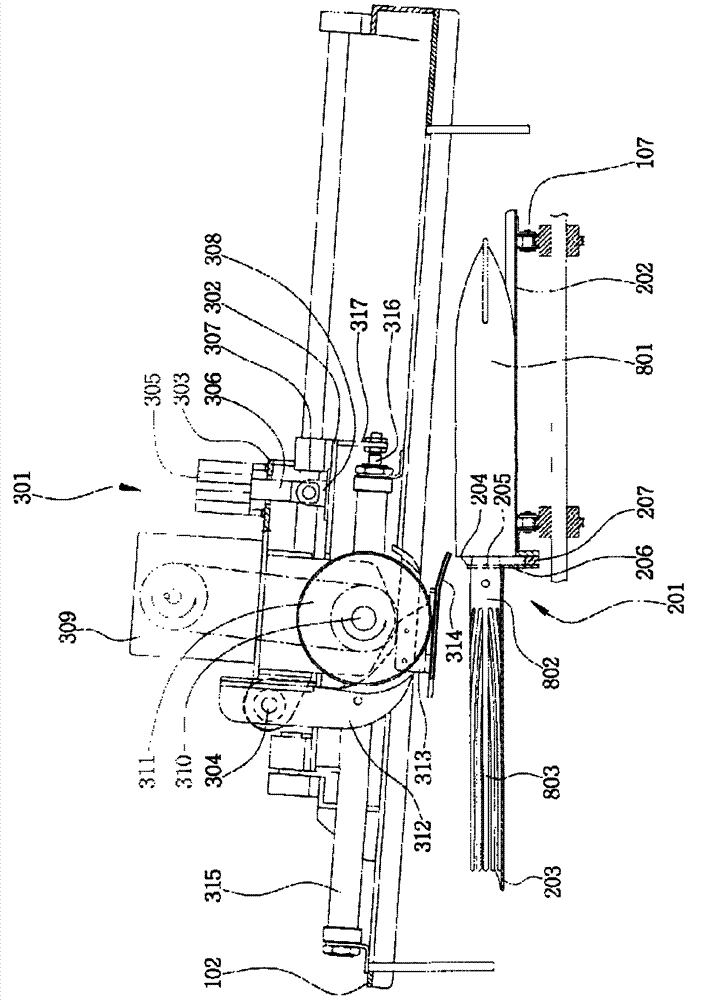

[0057] Hereinafter, the present invention will be described in detail in conjunction with the accompanying drawings.

[0058]The present invention has the following structure: a drive part 101, the drive part 101 includes a drive sprocket 104 that is driven by a drive motor 103 mounted on one side of the fuselage 102 to rotate, and the drive sprocket 104 is connected to the drive sprocket 104 through a drive tooth chain 105 The interlocking sprocket 106 (commonly known as coaxial double sprocket) on one side of the lower part of the fuselage 102 is used to drive the interlocking tooth chain 107 positioned at the lower side of the fuselage 102 to rotate through the interlocking sprocket 106 to form a horizontal conveying movement;

[0059] Squid transport part 201, this squid transport part 201 is combined on the linkage tooth chain 107 of drive part 101, thereby can carry squid through the drive of described drive part 101;

[0060] Trunk cutting part 301, this trunk cutting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com