New non-destructive detection method for morphology and distribution of pores in welding seam

A technology of non-destructive testing and new method, applied in the direction of using radiation for material analysis, etc., to achieve the effect of wide detection range and reduced sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

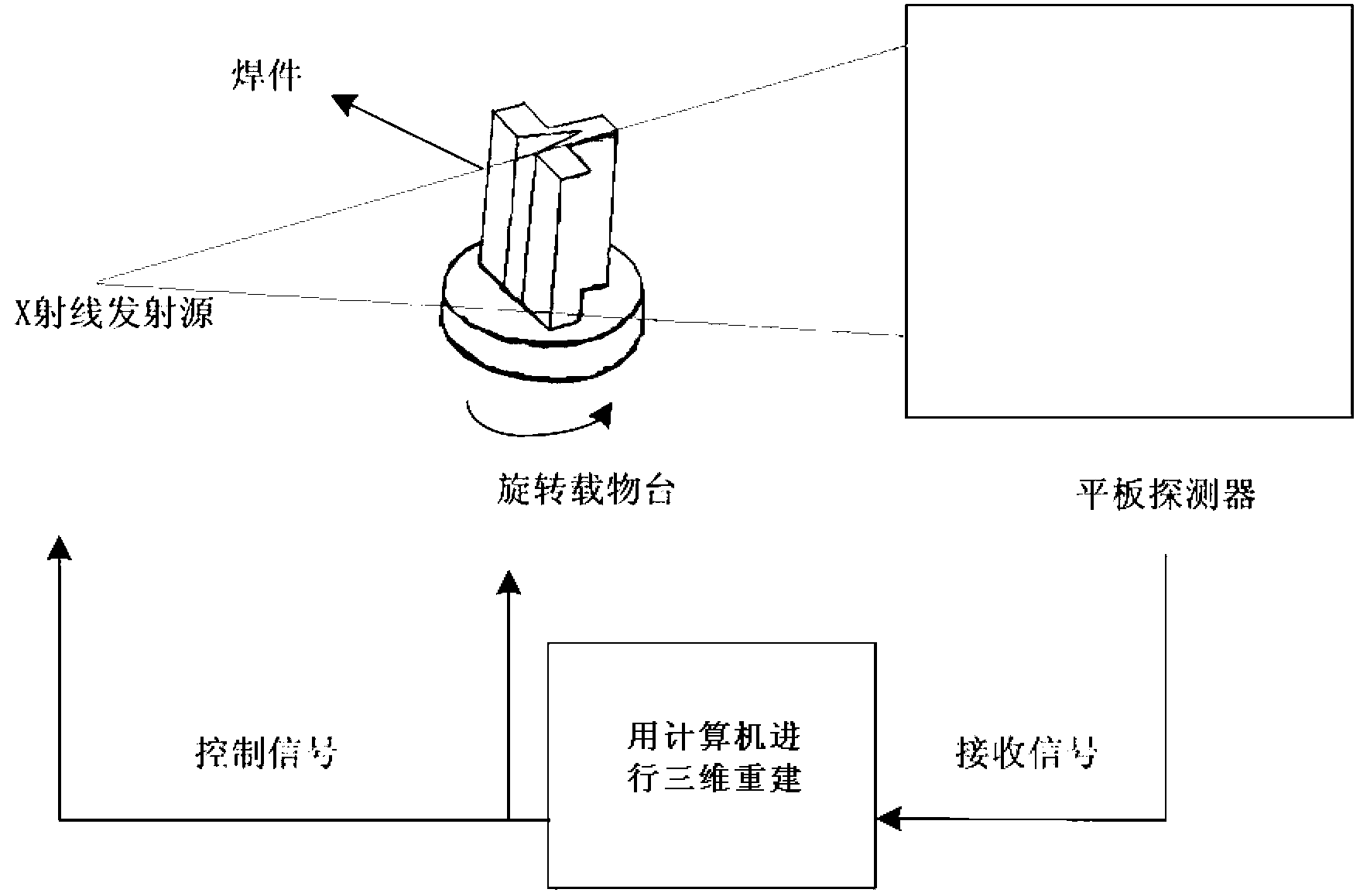

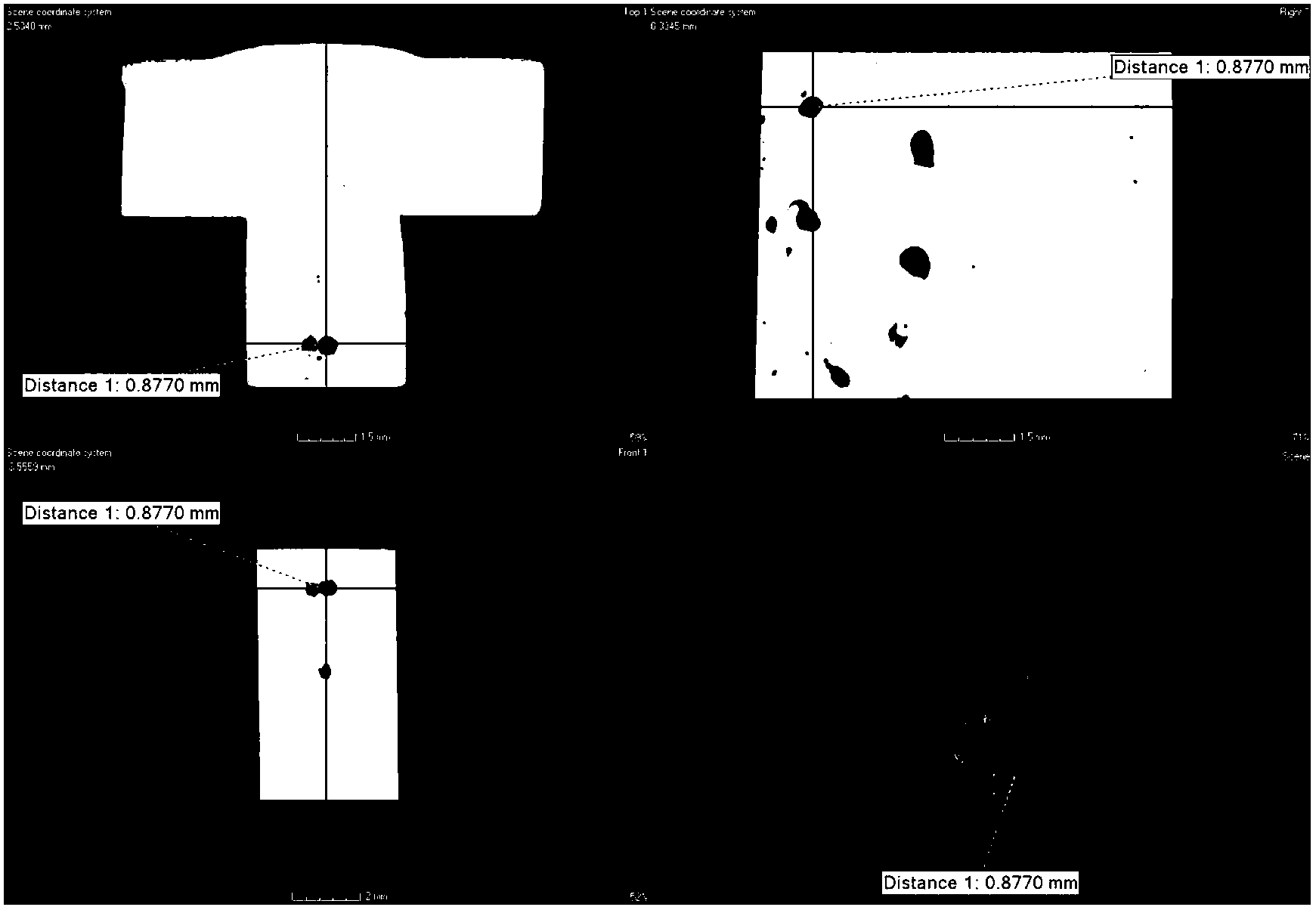

[0033] In this embodiment, the schematic diagram of the process of the detection method can be found in figure 1, here the laser welded low-carbon steel T-joint workpiece is selected for detection, because during the laser deep penetration welding process, due to the instability of the small holes, macroscopic pores are particularly easy to produce, so there are many pores in the selected welded components, and the detection and observation results Obviously, it is more conducive to testing the reliability of the method.

[0034] (1) First cut out the T-shaped weldment of appropriate size, and grind its surface with coarse sandpaper to remove surface splashes, inclusions and other attachments and impurities to make the surface smooth, and then use ultrasonic cleaning for 8 minutes to completely remove surface impurities; Wherein, the time of ultrasonic cleaning can be selected at any time within 5-10 minutes, and the above-mentioned 8 minutes is only an example;

[0035] (2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com