Low-heat-conduction multi-layer mullite brick and preparation method thereof

A multi-layer composite, mullite brick technology, used in lighting and heating equipment, ceramic products, other household appliances, etc., to improve thermal shock stability and corrosion resistance, energy saving and consumption reduction effect, excellent high temperature performance. Effect

Active Publication Date: 2013-08-07

郑州瑞泰耐火科技有限公司

View PDF7 Cites 46 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to overcome the shortcomings and deficiencies of the prior art, to provide a low thermal conductivity multilayer composite mullite brick and its preparation method, th

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Login to View More

Abstract

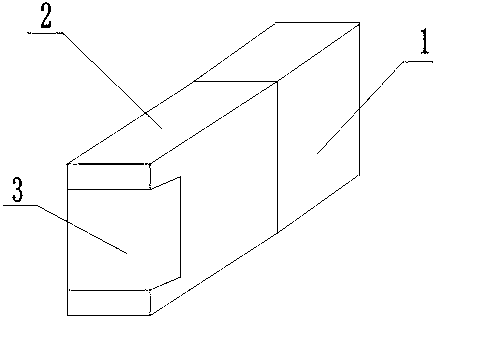

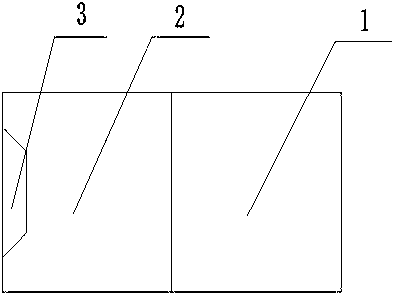

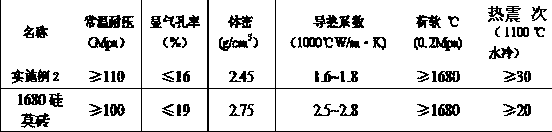

The invention discloses a low-heat-conduction multi-layer mullite brick and a preparation method thereof. Mullite with low heat conduction coefficient is utilized as a main raw material, a small amount of silicon carbide is added, a novel binding agent is utilized to replace clay, and a multi-layer composite structure is adopted. The heat conduction coefficient of a product is far lower than that of like products, thermal shock resistance and corrosion resistance of the product are greatly improved by means of excellent high temperature performance of the mullite, the service life of the product is prolonged, and simultaneously the energy-saving and consumption-reducing effect is obvious.

Description

technical field The invention relates to the technical field of refractory and environment-friendly materials, in particular to a low thermal conductivity multilayer composite mullite brick and a preparation method thereof. Background technique The upper and lower transition zones of the new dry-process cement rotary kiln are adjacent to the firing zone, and are often subjected to a harsher operating environment than the firing zone. Bricks are lining bricks. At present, most of the silica bricks sold in the market use first-grade or super-grade bauxite, and some companies also add fused corundum to improve the high-temperature performance and corrosion resistance of the product, but this also increases the thermal conductivity of silica bricks. The increase of the height makes the heat loss in the cement kiln faster, the fuel consumption per ton of cement increases, and the cylinder temperature rises, which easily deforms the cylinder and shortens the service life of the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F27B7/28F27D1/06C04B35/66C04B35/185C04B38/06

Inventor 郑建立李全有赵洪亮万远翔李沅锦

Owner 郑州瑞泰耐火科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com