External-rotor radial plunger hydraulic pump integrated with motors

A technology of radial columns and external rotors, which is applied to pumps, multi-cylinder pumps, mechanical equipment, etc., can solve the problems of many energy transmission links, the decrease of pump volume efficiency, and the easy generation of air bubbles in oil, so as to improve the utilization of energy High efficiency, avoiding the decline of volumetric efficiency, and high energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

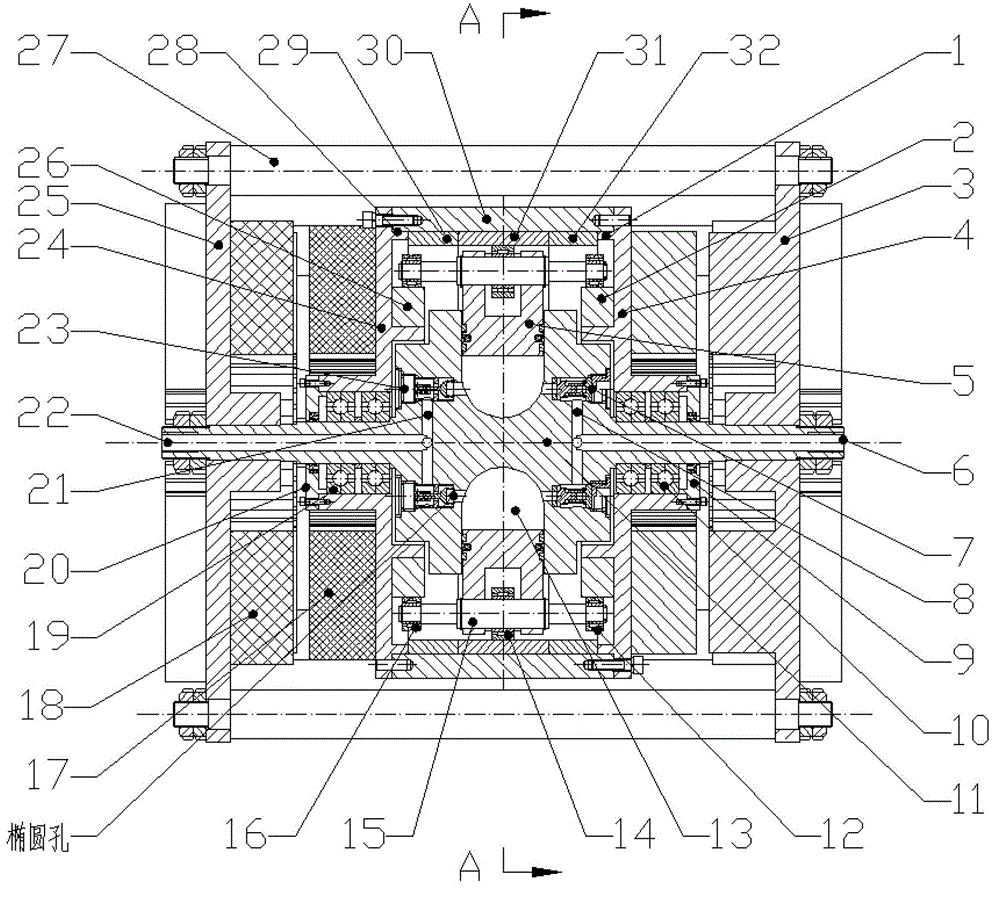

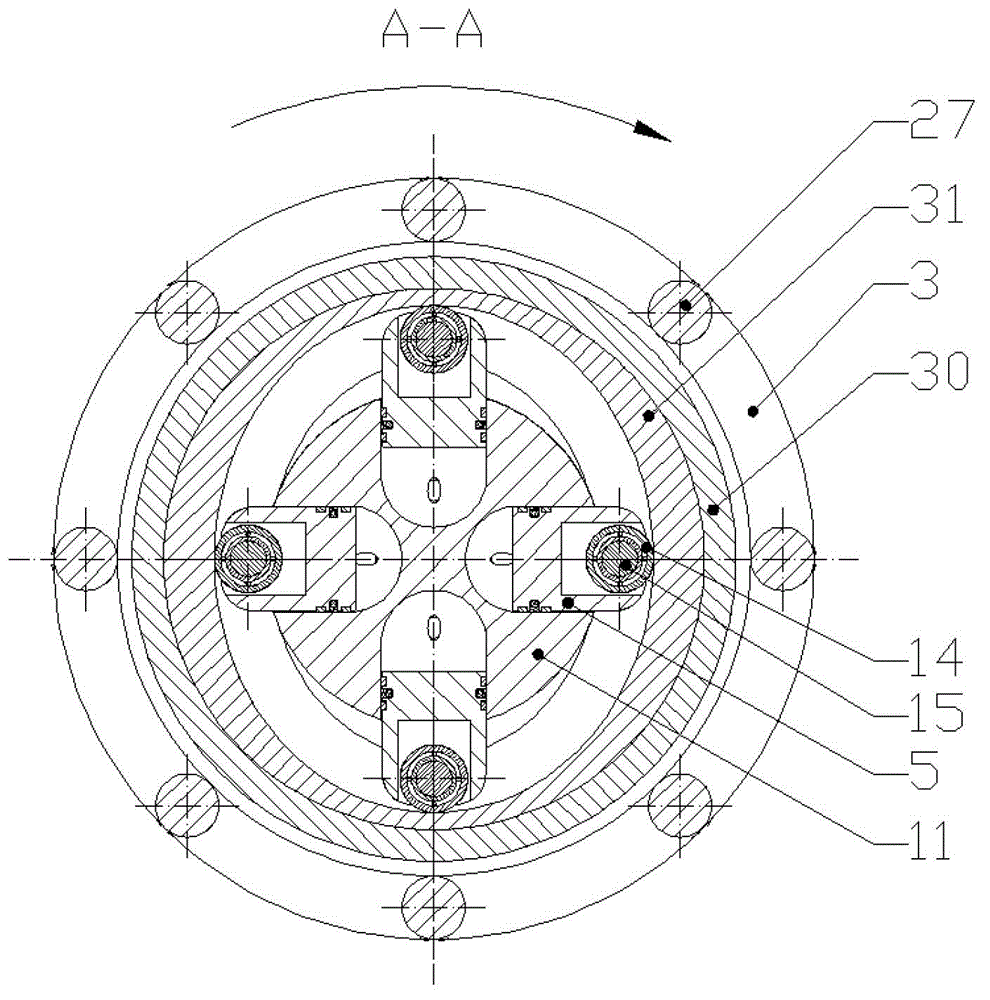

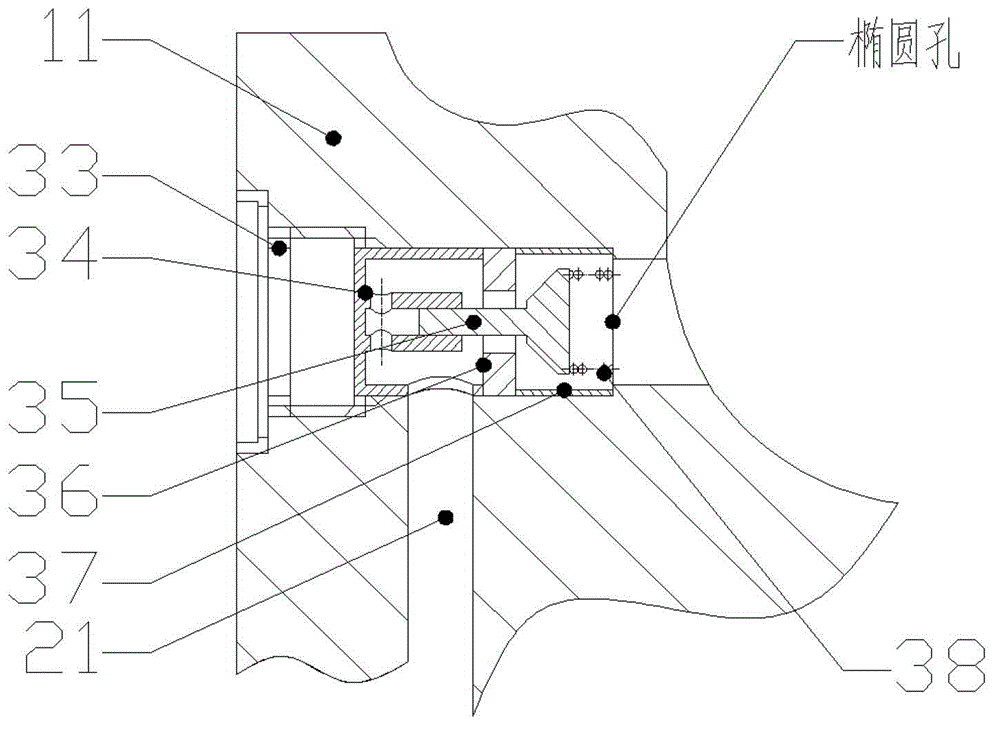

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] refer to figure 1 and figure 2 , an outer rotor radial plunger hydraulic pump integrated with a motor, including a first outer end cover 25 and a second outer end cover 3, the first outer end cover 25 and the second outer end cover 3 are arranged oppositely, through two More than two connecting rods 27 are connected and locked with round nuts to form an overall structure and be fixed to the ground. The pump stator 11 is installed inside the overall structure, and the shafts on both sides of the pump stator 11 are connected from the first outer end cover 25 and the The square through hole in the center of the two outer end covers 3 protrudes, and the protruding part is locked with a round nut. In the matching part, planes are cut out on the shafts on both sides of the pump stator 11, and the first outer end cover 25 and the second The square through hole in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com