Al-Er-Zr-Si aluminum alloy and heat treatment process

An alloy and process technology, which is applied in the field of Si-containing Al-Er-Zr alloy and heat treatment process, can solve the problem of high price, achieve the effects of increasing strength, reducing cost, and improving the effect of aging strengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0011] Example: Al99.99 high-purity aluminum is selected, and the contents of Al-Zr, Al-Er and Al-Si master alloys are 4%, 6% and 40% (mass ratio) respectively. First melt pure aluminum, after the pure aluminum is melted, put into the intermediate alloy, the melting temperature is 780 ℃ ~ 800 ℃, let it stand for 30 minutes after reaching the melting temperature, and then cast in an iron mold. The composition of the prepared alloy elements is shown in Table 1.

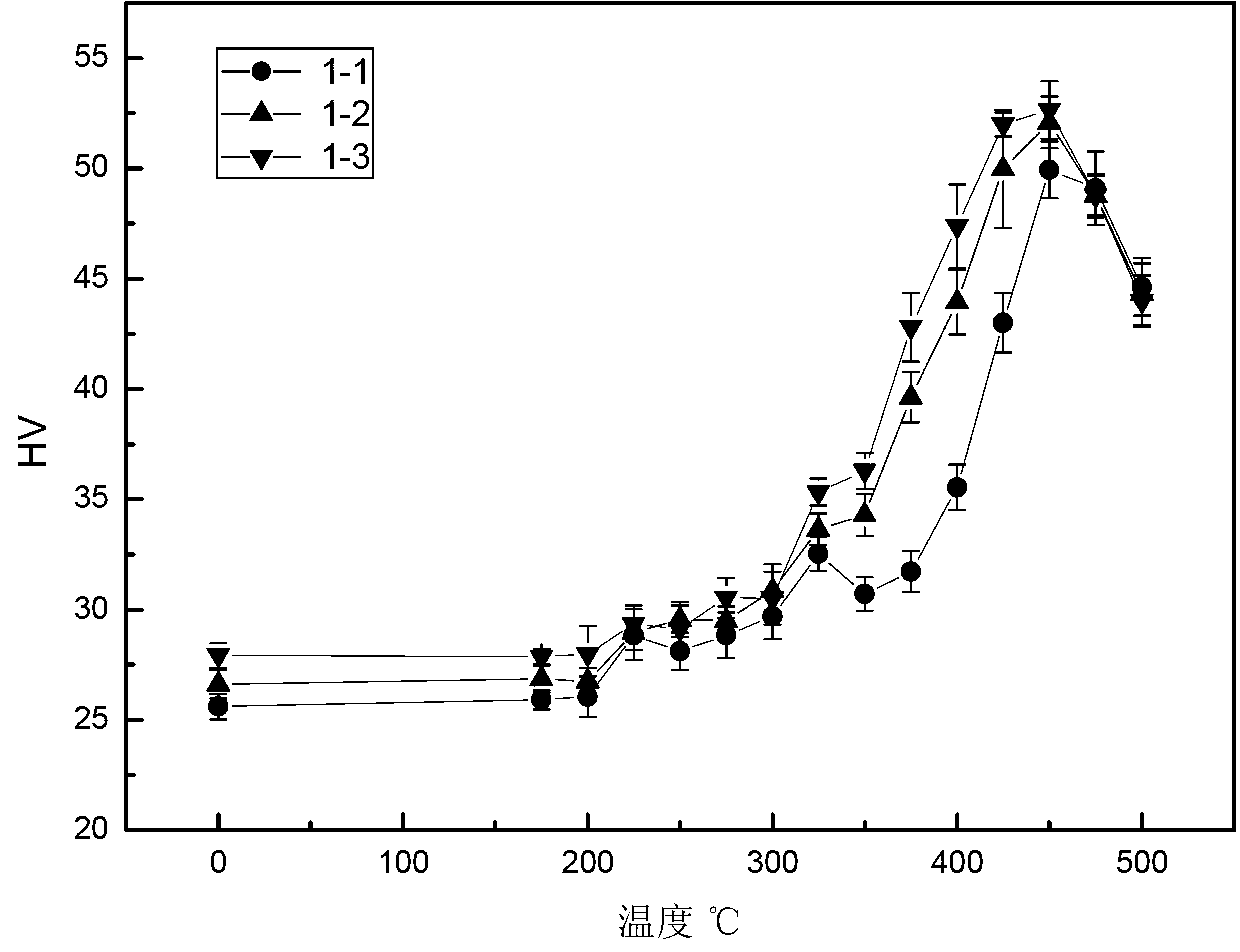

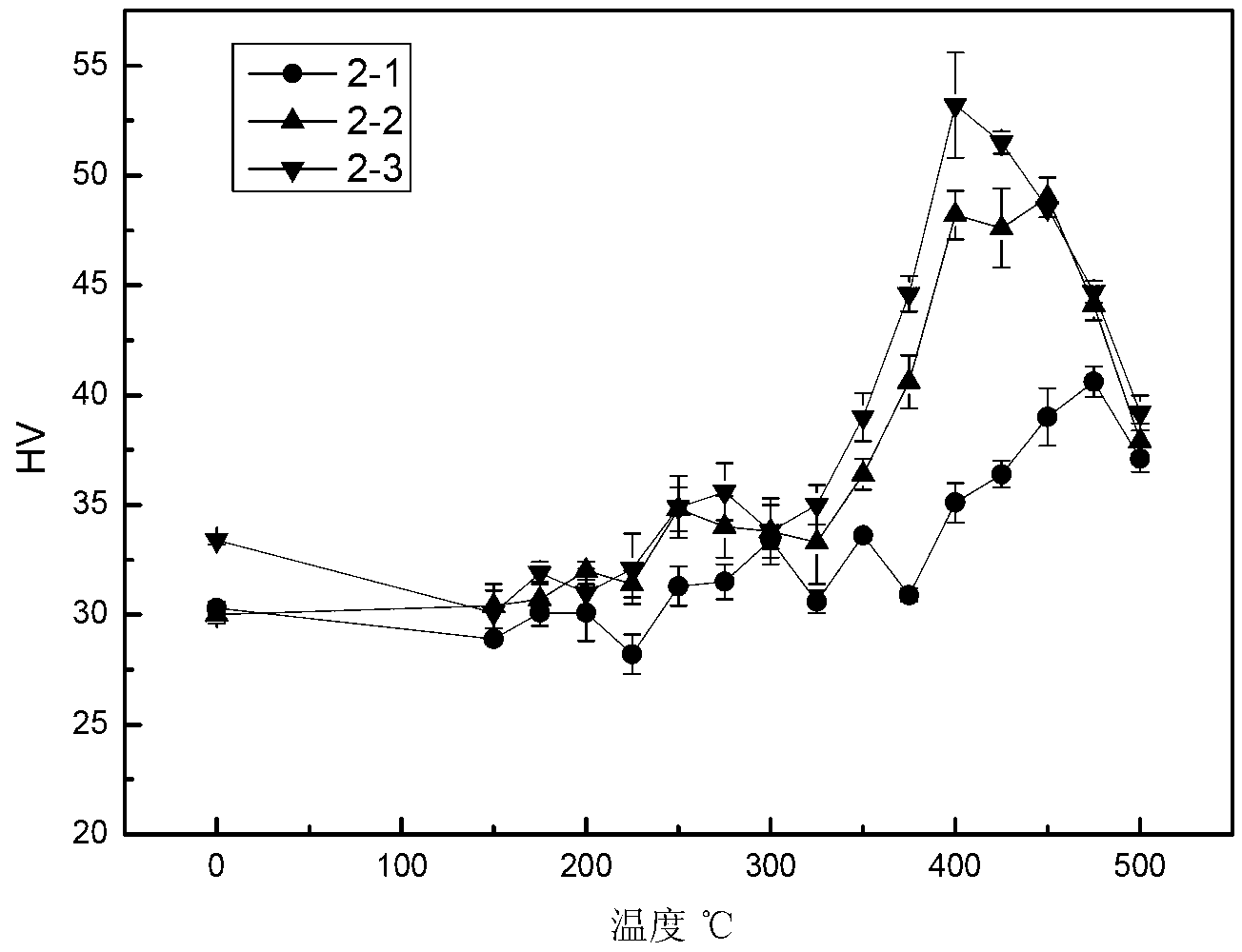

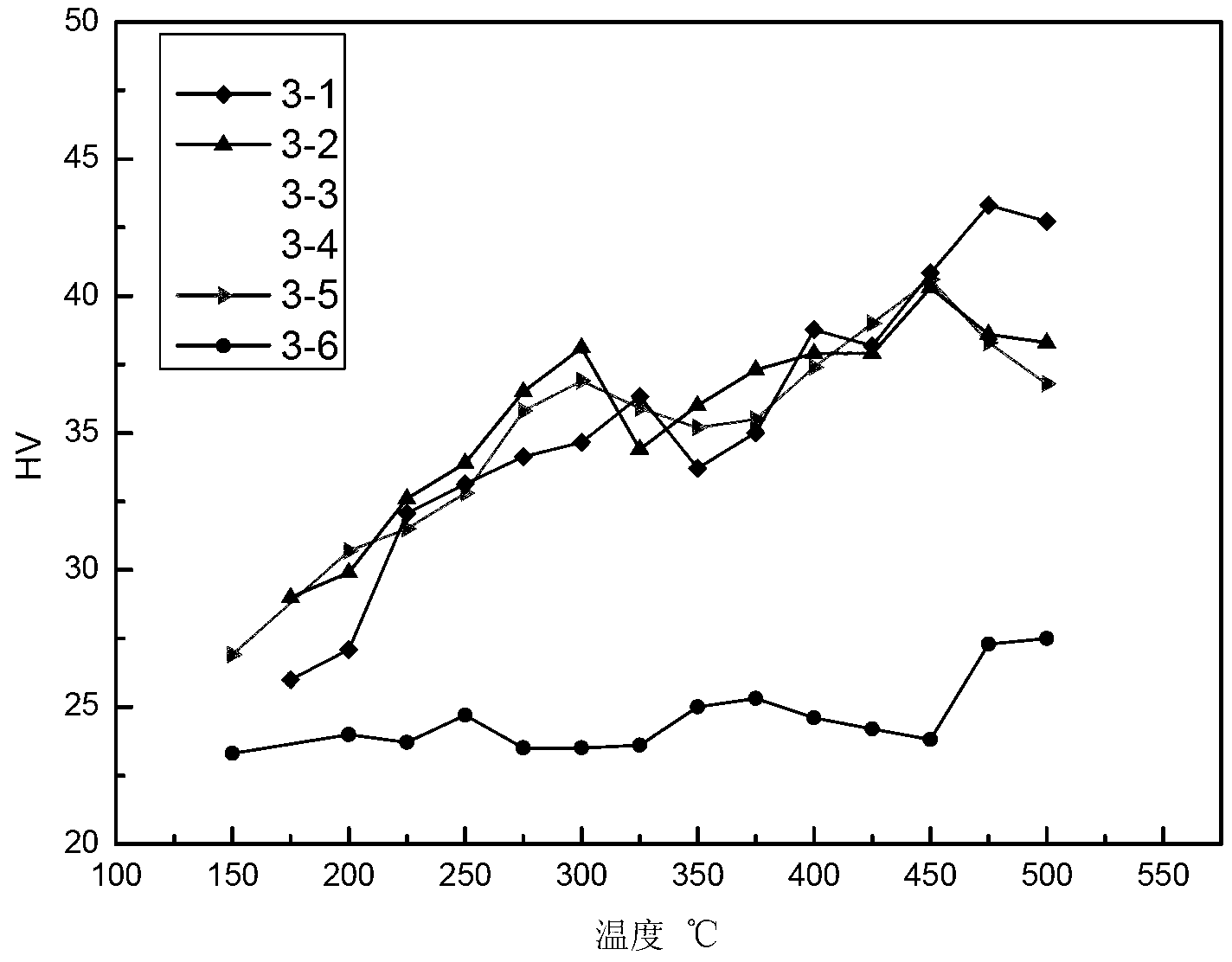

[0012] The ingot of the alloy with the above composition was cold-rolled, then kept at 640±10°C for 48 hours, water quenched to room temperature, aged at 150-500°C at intervals of 25°C for 2 hours, and then tested for microhardness. figure 1 is the change curve of microhardness with temperature in the isochronous process of Al-0.05Er-0.3Zr-xSi alloy; figure 2 is the change curve of microhardness with temperature in the isochronous process of Al-0.07Er-0.2Zr-xSi alloy;

[0013] Table 1 example experimental alloy compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com