Double-column horizontal machining center with vertically moving worktable

A vertically moving, machining center technology, applied in metal processing, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of high modification difficulty, high cost, and difficulty in realizing dual-spindle modular expansion, and achieves the transformation of machine tools. It is easy to type, and the effect of increasing the speed of fast movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

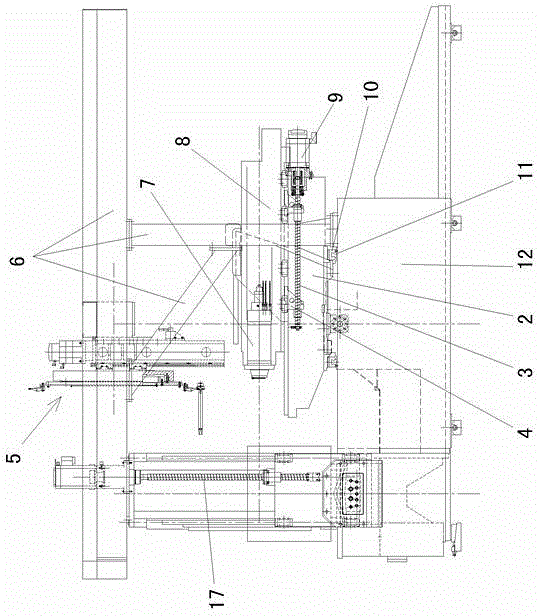

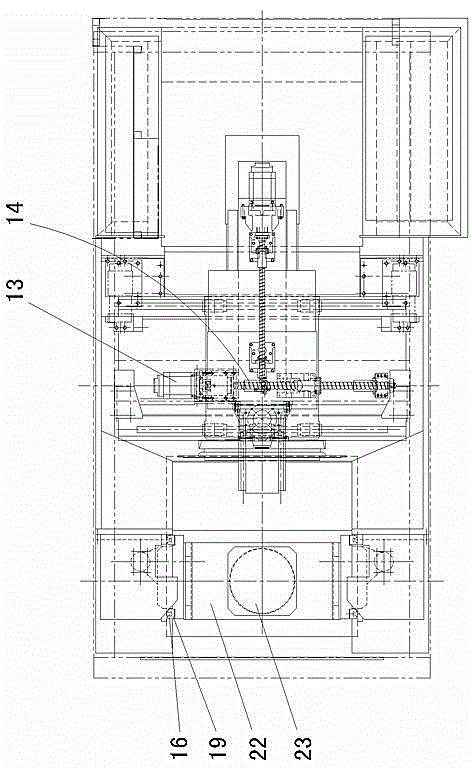

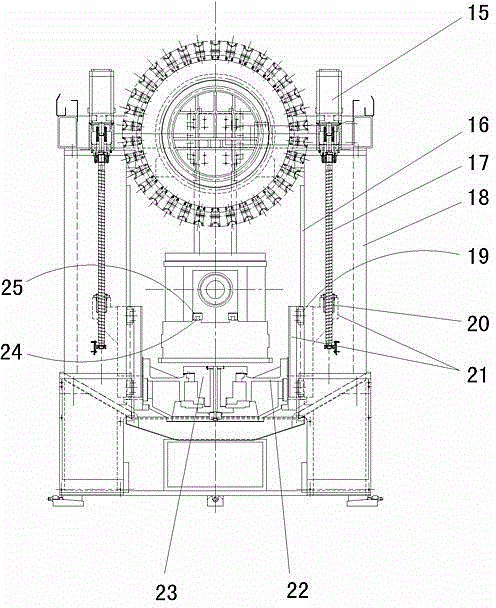

[0022] Such as figure 1 , 2 , shown in 3: 12 is a bed, 18 is a column, 23 is a rotatable workbench, and 22 is a support for the workbench supporting the workbench 23.

[0023] There are two upright columns 18 and they are vertically arranged parallel to each other on both sides of one end of the bed 12, and are fixedly connected with the bed 12.

[0024] The workbench support 22 is connected with the column 18 slidingly and is equipped with a lifting mechanism that drives the workbench to rise or fall. Concrete structure is as follows: the inboard both sides of each upright post 18 is provided with vertical slide rail 16, and vertical slide rail 16 is totally four and mutually symmetrically arranged. Both sides of the workbench support 22 are fixedly connected with a workbench lifting frame 21, and the workbench lifting frame 21 is fixedly connected with a workbench lifting slider 19 matched with the vertical slide rail 16. Workbench elevating motor 15 is installed on each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com