Preparation method of wall thickness controllable directional solidification casting mould

A directional solidification and casting technology, which is used in casting molding equipment, casting molds, casting mold components, etc., can solve the problems of difficulty in precise control of the mold shell and precise control of the temperature field of the mold shell, so as to achieve industrialized production and improve directional solidification. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0062] A method for preparing a directional solidification mold with controllable wall thickness, comprising the following steps:

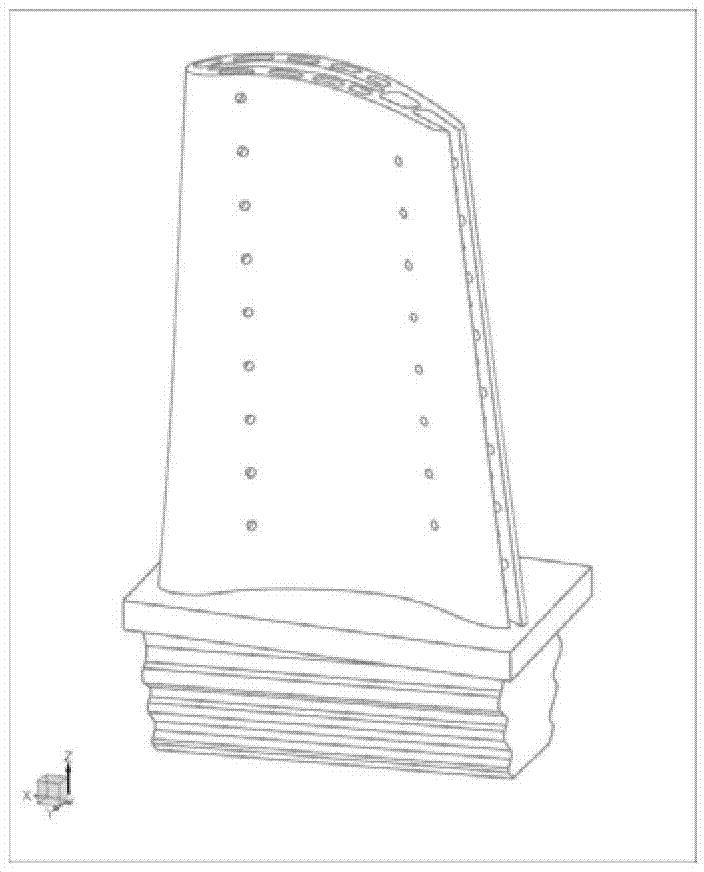

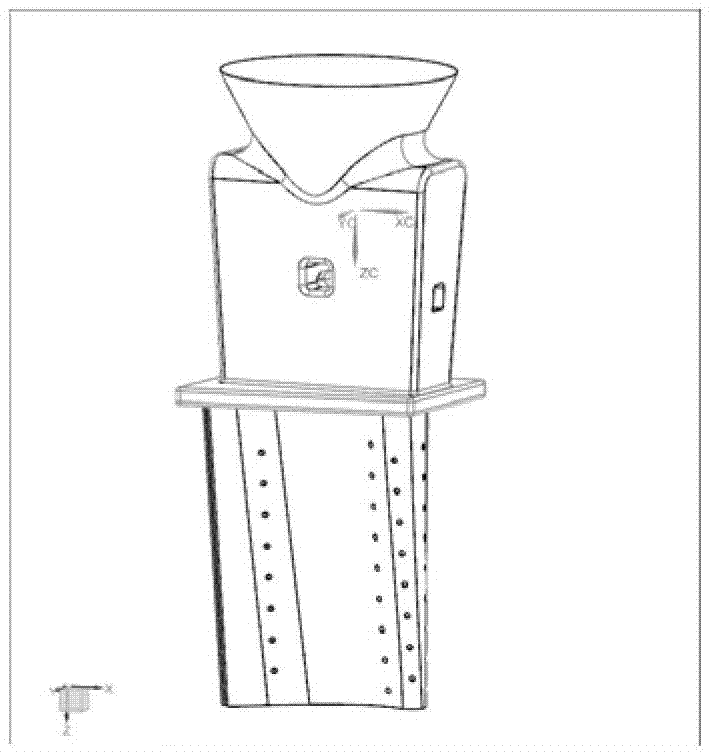

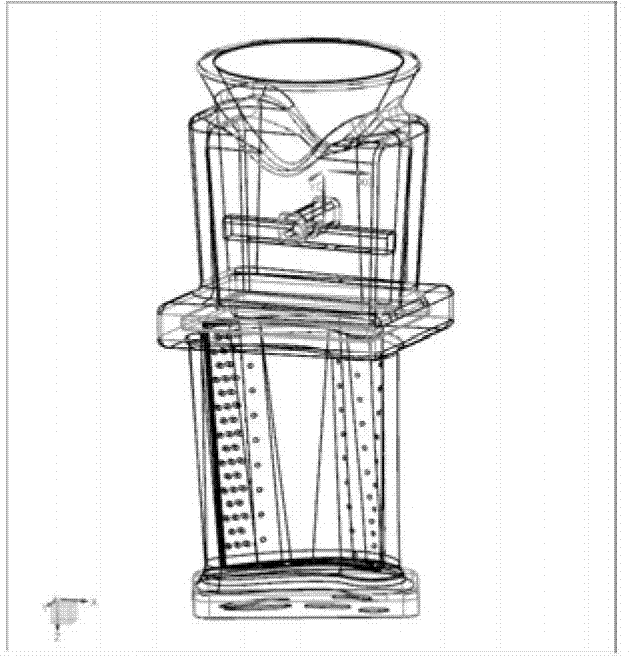

[0063] 1) According to the structure of the casting to be prepared, design the initial mold with uniform wall thickness in the 3D software;

[0064] 2) Import the initial mold into the casting software for heat conduction analysis and stress analysis; in the process of stress calculation, change the shape of the outer wall of the mold shell to reduce the stress in the stress concentration area until the stress concentration is eliminated or reduced Stress concentration; according to the thermal stress distribution at each moment, select the wall thickness that conforms to the thermal intensity and the minimum stress, and use this wall thickness as the uniform wal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific heat capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com