Rolling method of TC4 titanium alloy wide cut medium-thickness plates

A titanium alloy, wide-width technology, applied in the direction of metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of small anisotropy of thick plates, large plate anisotropy, and cannot meet the requirements of titanium alloys, etc., to achieve reduction Small anisotropy, small anisotropy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

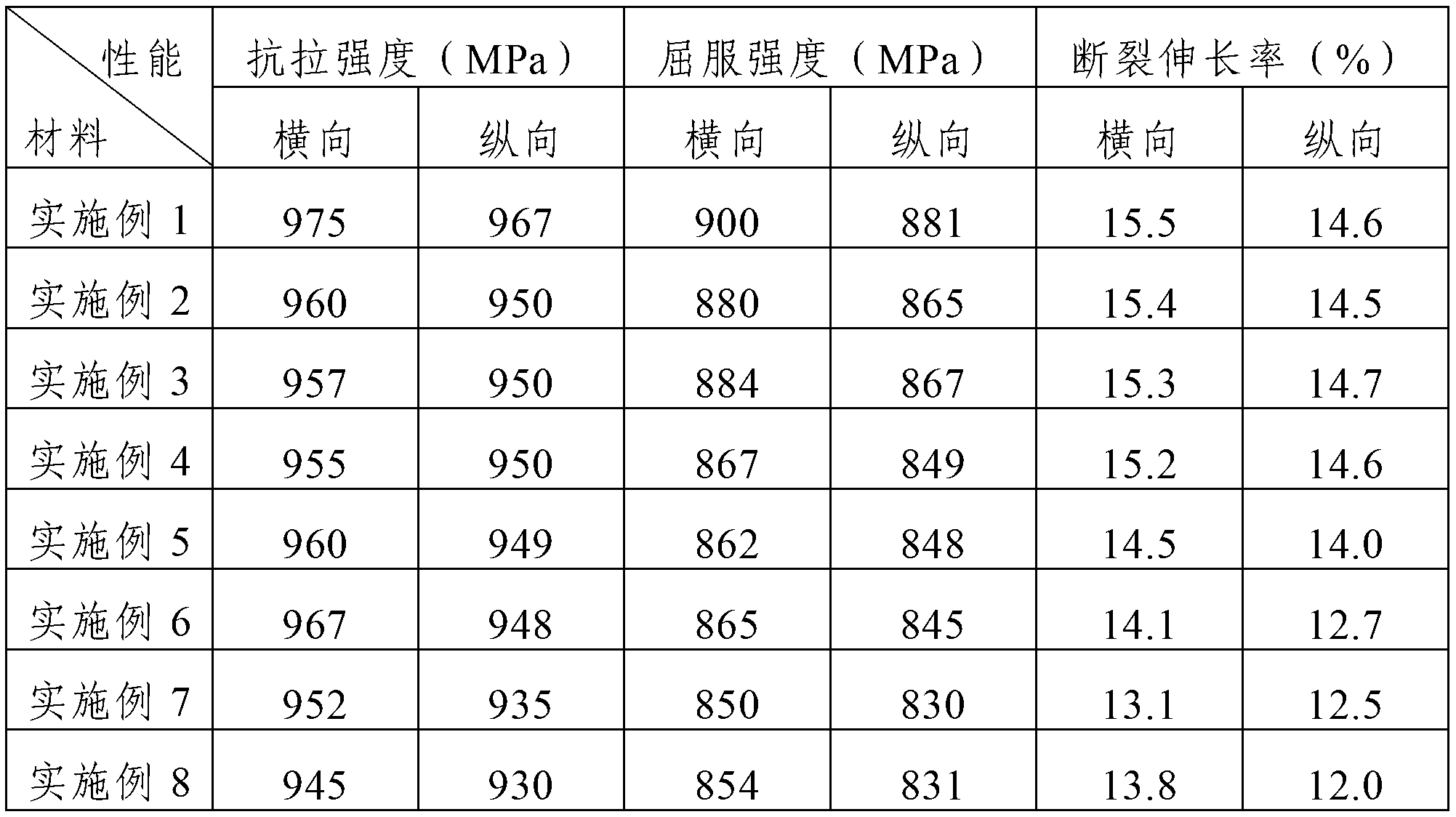

Examples

Embodiment 1

[0025] The rolling method of the present embodiment TC4 titanium alloy wide medium-thick plate comprises the following steps:

[0026] Step 1. Place a TC4 titanium alloy slab with a thickness of 150mm and a length and width of 1200mm in a roller hearth heating furnace, and heat it for 80 minutes at a temperature of 940°C for the first heat treatment;

[0027] Step 2. Send the TC4 titanium alloy slab after the first heat treatment in the step 1 into the 2800mm hot rolling mill along the length direction or the width direction for the first rolling to obtain a semi-finished slab with a thickness of 67.1mm and a width of 1200mm billet; the first rolling is one-way rolling, and the temperature of the TC4 titanium alloy slab is monitored by an infrared thermometer during the first rolling process, and the temperature of the TC4 titanium alloy slab is controlled to not be lower than 900°C , the specific process is: when the temperature of the TC4 titanium alloy slab drops to 905°C, ...

Embodiment 2

[0032] The rolling method of the present embodiment TC4 titanium alloy wide medium-thick plate comprises the following steps:

[0033] Step 1. Place a TC4 titanium alloy slab with a thickness of 80mm, a width of 800mm, and a length of 1200mm in a roller-hearth heating furnace, and heat it for 60 minutes at a temperature of 950°C for the first heat treatment;

[0034]Step 2, sending the TC4 titanium alloy slab after the first heat treatment in the step 1 into a 2800mm hot rolling mill along the length direction for the first rolling to obtain a semi-finished slab with a thickness of 20mm and a width of 800mm; The first rolling is one-way rolling, and an infrared thermometer is used to monitor the temperature of the TC4 titanium alloy slab during the first rolling process, and the temperature of the TC4 titanium alloy slab is controlled to not be lower than 900°C. The specific process It is: when the temperature of the TC4 titanium alloy slab drops to 910°C, the TC4 titanium all...

Embodiment 3

[0039] The rolling method of the present embodiment TC4 titanium alloy wide medium-thick plate comprises the following steps:

[0040] Step 1. Place a TC4 titanium alloy slab with a thickness of 120mm and a length and width of 800mm in a roller hearth heating furnace for the first heat treatment; the temperature of the first heat treatment is 930°C, and the first The time of heat treatment is 120min;

[0041] Step 2. Send the TC4 titanium alloy slab after the first heat treatment in step 1 into a 2800mm hot rolling mill along the length direction or width direction for the first rolling to obtain a semi-finished slab with a thickness of 49mm and a width of 800mm ; The first rolling is one-way rolling, and the temperature of the TC4 titanium alloy slab is monitored by an infrared thermometer during the first rolling process, and the temperature of the TC4 titanium alloy slab is controlled to be not lower than 900°C , the specific process is: when the temperature of the TC4 tit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com