A kind of acid-alkali corrosion-resistant water-resistant wear-resistant floor coating and preparation method thereof

A floor coating, acid and alkali resistance technology, used in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of floor surface scratches, increased coating brittleness, limited cross-linking degree, etc., and achieve oil resistance. The effect of good performance, excellent mechanical properties and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

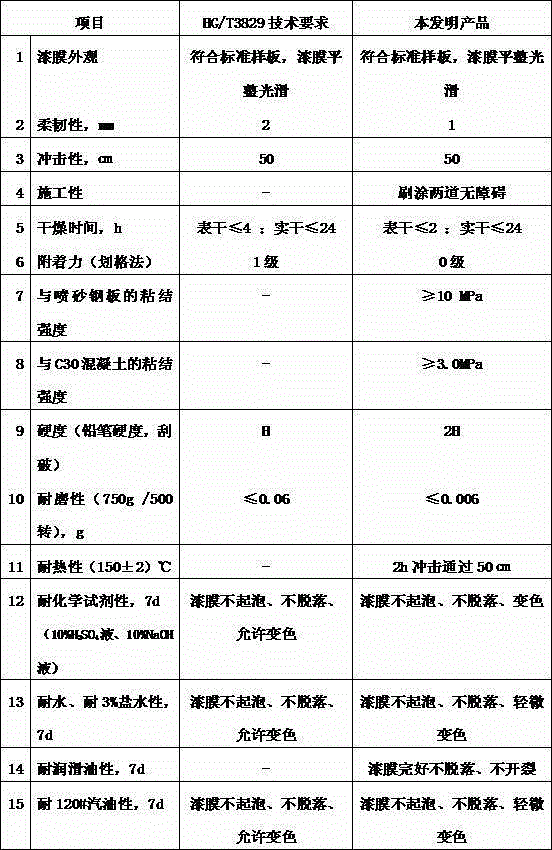

Examples

Embodiment 1

[0030] The coating composition and proportioning of the present embodiment are:

[0031] Isocyanate curing agent component (referred to as group A): Polymerized MDI (PM200) polyether prepolymer solution (Jiangsu Shanli Paint Industry Co., Ltd.) 50%; hydroxyl-containing paint component (referred to as group B): BS965 hydroxyl acrylic resin (Jiangsu Sanmu Chemical Co., Ltd.) 17.5%, polymer 6101 epoxy resin polymer (Jiangsu Sanmu Chemical Co., Ltd.) 2.5%, 582-2 amino resin (Jiangsu Sanmu Chemical Co., Ltd.) 1.1%, pigment (Zhenjiang Titanium Dioxide Co., Ltd. Company) 18%, xylene (Jiangsu Sanmu Chemical Co., Ltd.) 8%, butyl acetate (Jiangsu Sanmu Chemical Co., Ltd.) 2%, BYK defoamer (BYK066N) 0.2%, 1% methyl silicone oil 0.2%, organic clay 0.5%.

[0032] The isocyanate curing agent components (group A for short) are: polymeric MDI (PM200) polyether prepolymer (Yantai Wanhua Polyurethane Co., Ltd.) 41.32%, N204 polyether (Jiangsu Sanmu Chemical Co., Ltd.) 8.26%, N330 polyether Et...

Embodiment 2

[0034] The coating composition and proportioning of the present embodiment are:

[0035] Isocyanate curing agent component (group A for short): Polymerized MDI (PM200) polyether prepolymer solution (Jiangsu Shanli Paint Industry Co., Ltd.) 65%; hydroxyl-containing paint component (group B for short): BS965 hydroxyl acrylic resin (Jiangsu Sanmu Chemical Co., Ltd.) 12.3%, polymer 6101 epoxy resin polymer (Jiangsu Sanmu Chemical Co., Ltd.) 1.6%, 582-2 amino resin (Jiangsu Sanmu Chemical Co., Ltd.) 1%, pigment (Zhenjiang Titanium Dioxide Co., Ltd. Company) 13%, xylene (Jiangsu Sanmu Chemical Co., Ltd.) 5%, butyl acetate (Jiangsu Sanmu Chemical Co., Ltd.) 1.4%, BYK defoamer (BYK066N) 0.15%, 1% methyl silicone oil 0.15%, organic clay 0.4%.

[0036] The isocyanate curing agent components (group A for short) are: polymeric MDI (PM200) polyether prepolymer (Yantai Wanhua Polyurethane Co., Ltd.) 41.32%, N204 polyether (Jiangsu Sanmu Chemical Co., Ltd.) 8.26%, N330 polyether Ether (Jia...

Embodiment 3

[0038] The coating composition and proportioning of the present embodiment are:

[0039] Isocyanate curing agent component (referred to as group A): Polymerized MDI (PM200) polyether prepolymer solution (Jiangsu Shanli Paint Industry Co., Ltd.) 80%; hydroxyl-containing paint component (referred to as group B): BS965 hydroxyl acrylic resin (Jiangsu Sanmu Chemical Co., Ltd.) 7%, polymer 6101 epoxy resin polymer (Jiangsu Sanmu Chemical Co., Ltd.) 1%, 582-2 amino resin (Jiangsu Sanmu Chemical Co., Ltd.) 0.6%, pigment (Zhenjiang Titanium Dioxide Co., Ltd. Company) 7%, xylene (Jiangsu Sanmu Chemical Co., Ltd.) 3%, butyl acetate (Jiangsu Sanmu Chemical Co., Ltd.) 1%, BYK defoamer (BYK066N) 0.1%, 1% methyl silicone oil 0.1%, organic clay 0.2%.

[0040] The isocyanate curing agent components (group A for short) are: polymeric MDI (PM200) polyether prepolymer (Yantai Wanhua Polyurethane Co., Ltd.) 41.32%, N204 polyether (Jiangsu Sanmu Chemical Co., Ltd.) 8.26%, N330 polyether Ether (J...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com