Synthesis method of trioctyl phosphate

A technology of trioctyl phosphate and crude ester, which is applied in the chemical industry, can solve problems such as corrosion of production equipment, many reaction steps, and environmental pollution, and achieve the effects of energy saving, short reaction cycle, and increased economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

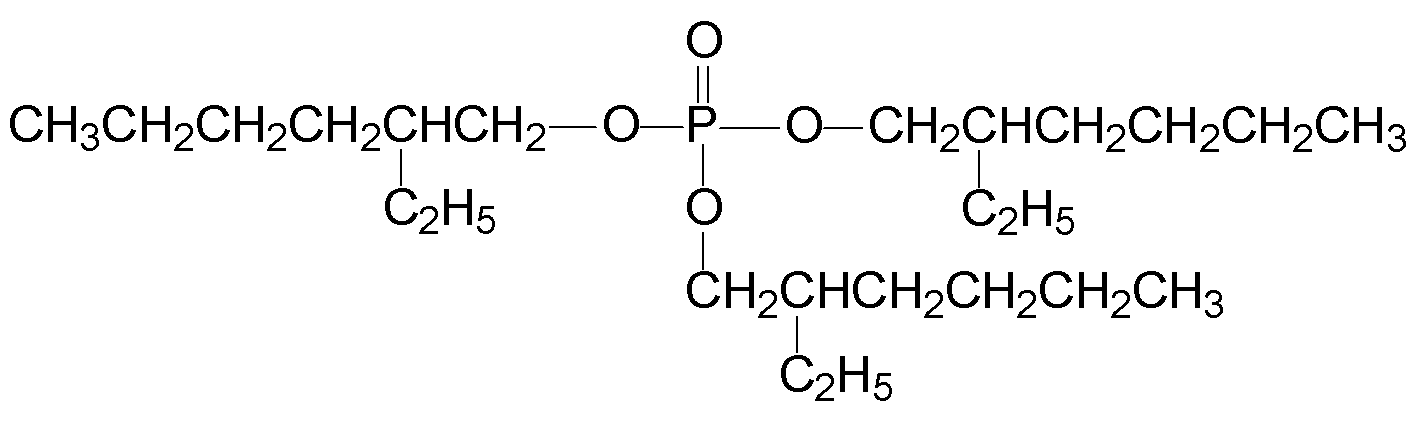

[0031] A kind of preparation method of trioctyl phosphate, general idea is as follows:

[0032] Step 1: Add phosphorus oxychloride dropwise to isooctyl alcohol to generate crude ester for synthesis reaction.

[0033] The second step: neutralize and balance the crude ester in the first step of transfer with alkaline solution.

[0034] The third step: wash the wet crude ester separated in the second step with hot water.

[0035] The fourth step: the final product trioctyl phosphate (TOP) is obtained by distilling and dehydrating the wet crude ester qualified in the third step.

[0036] To sum up, the production of trioctyl phosphate is to add phosphorus oxychloride dropwise to the raw material isooctyl alcohol at low temperature to react at a specified temperature (58-65°C); and pay attention to the discharge of hydrogen chloride to make the reaction go to the end, and then pass through alkali Neutralize and balance, wash with water until neutral, and distill under reduced pre...

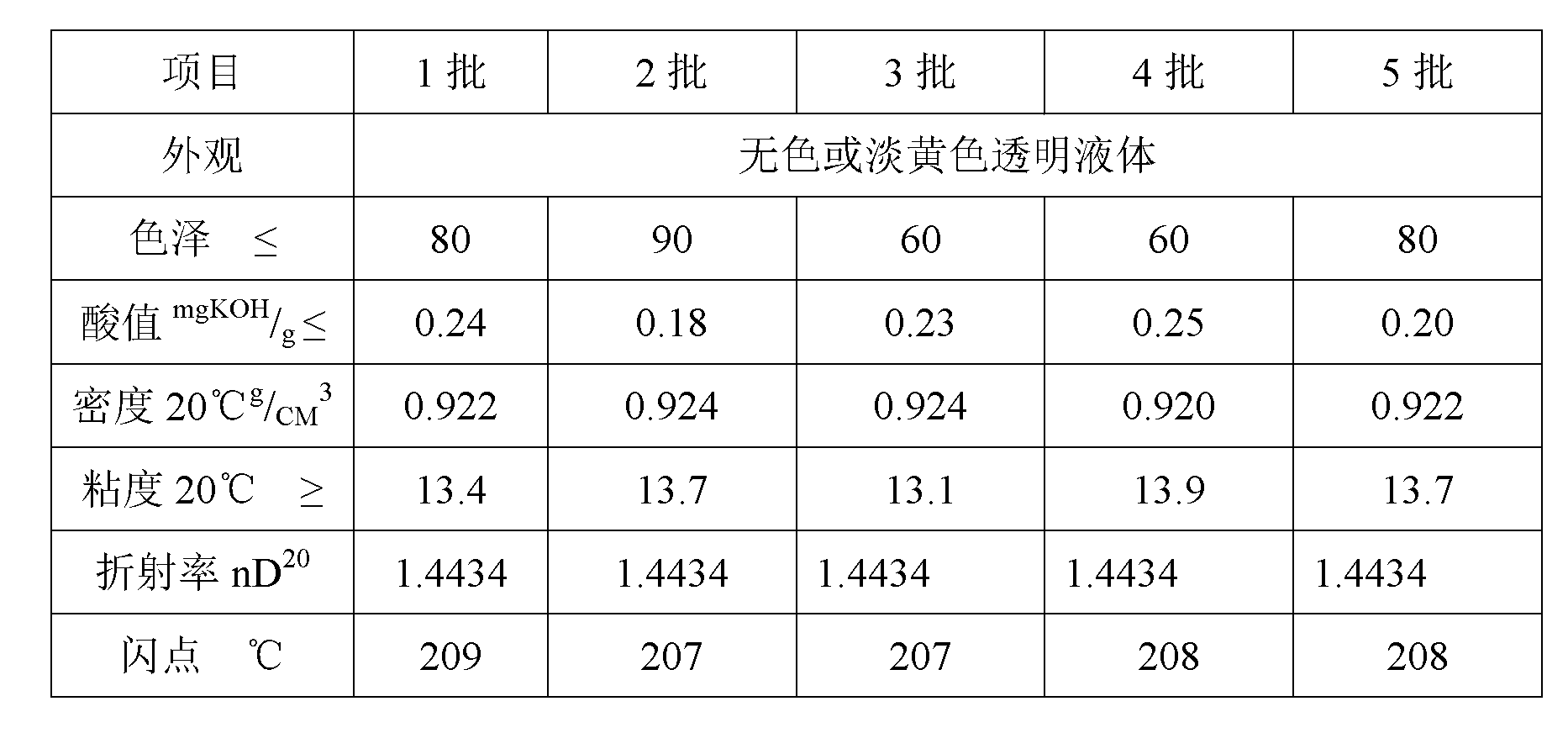

Embodiment 1

[0045] A preparation method of trioctyl phosphate, the steps are as follows:

[0046] 1. Synthesis process:

[0047] According to the ratio of raw materials, put 280 kg of isooctyl alcohol into the synthesis tank, pump 115 kg of phosphorus oxychloride into the high-level tank; start the stirring of the synthesis tank, and raise the temperature to 47~53 °C through the jacket, Start to add phosphorus oxychloride dropwise to the synthesis kettle, control the temperature at 65±2°C, finish the addition within 4~6 hours, and continue to react for 4~6 hours to balance the acid produced by the reaction, use the acid absorber and collection tank The crude ester can be obtained by circulating the pump or absorbing with dilute alkali.

[0048] 2. Neutralization and balance process

[0049] Transfer the crude ester to the neutralization tank of the added lye (mass concentration: 3-5%, mass ratio of crude ester: lye: 4:1) for stirring and neutralization, time 1-1.5 Hours, temperature 70...

Embodiment 2

[0055] A preparation method of trioctyl phosphate, the steps are as follows:

[0056] 1. Synthesis process:

[0057] According to the ratio of raw materials, put 720 kg of isooctyl alcohol into the synthesis tank, pump 400 kg of phosphorus oxychloride into the high-level tank; start the stirring of the synthesis tank, and raise the temperature to 47~53 °C through the jacket, Start to add phosphorus oxychloride dropwise to the synthesis kettle, control the temperature at 65±2°C, finish the addition within 4~6 hours, and continue to react for 4~6 hours to balance the acid produced by the reaction, use the acid absorber and collection tank The crude ester can be obtained by circulating the pump or absorbing with dilute alkali.

[0058] 2. Neutralization and balance process

[0059]Transfer the crude ester to a 400 kg neutralization tank with added lye (mass concentration 3~5%) for 1~1.5 hours, temperature 70±3°C, and neutralize to control pH The value is 8~9; after passing thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com