Composite matrix based carrier modified asphalt self-adhesive waterproof coiled material

A waterproof membrane and modified asphalt technology, which is applied in asphalt coatings, asphalt layered products, roofs using flexible materials, etc., can solve the problems of natural resource consumption, heavy purchase cost burden, waterproof material consumption, etc., and achieve low resource consumption. The effect of consumption, high waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

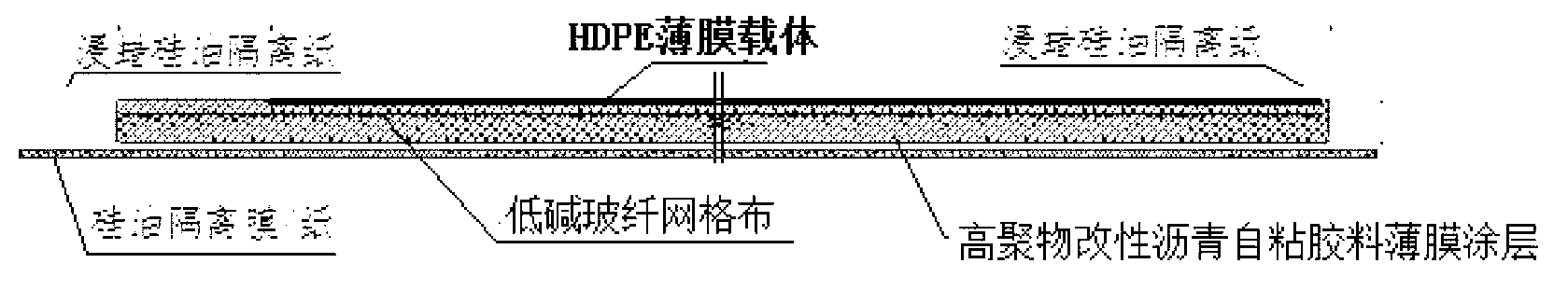

[0040] Its specific product structure of the waterproof roll material of the present invention can be included in the attached figure 1 shown in the attached figure 1 In the above, the applicant provided a typical specific structure of the waterproof roll material of the present invention: HDPE (molecular weight 160000) film thickness is 0.15mm, modified asphalt self-adhesive adhesive film coating thickness is 1.35mm, glass fiber mesh The cloth specification is 60g / m 2 , the overall length of the waterproof membrane is 1000mm, one end of the HDPE film is completely covered with the modified asphalt self-adhesive film coating, and the other end is left with a 25mm exposed strip, and the glass fiber mesh cloth traverses the entire modified asphalt self-adhesive film Coating, located at a depth of 1mm below its surface.

[0041] The release paper in the attached drawings (both sides of the upper surface are wax-impregnated silicone oil release paper, and the lower surface is si...

Embodiment 2

[0054] A product structure similar to Example 1, wherein the film thickness of HDPE (molecular weight 280000) is 0.2mm, the coating thickness of the modified asphalt self-adhesive adhesive film is 1.95mm, the specification of glass fiber mesh cloth is 110g / m2, and the waterproof membrane The overall length of the HDPE film is 1000mm. One end of the HDPE film is completely covered with the modified asphalt self-adhesive adhesive film coating, and the other end is left with a 20mm exposed strip. The glass fiber mesh cloth traverses the entire modified asphalt self-adhesive adhesive film coating. Its depth is 0.6mm below the surface.

[0055] The glass fiber mesh cloth is low-alkali glass fiber mesh cloth, and the content of metal sodium potassium oxide is not higher than 1.5%.

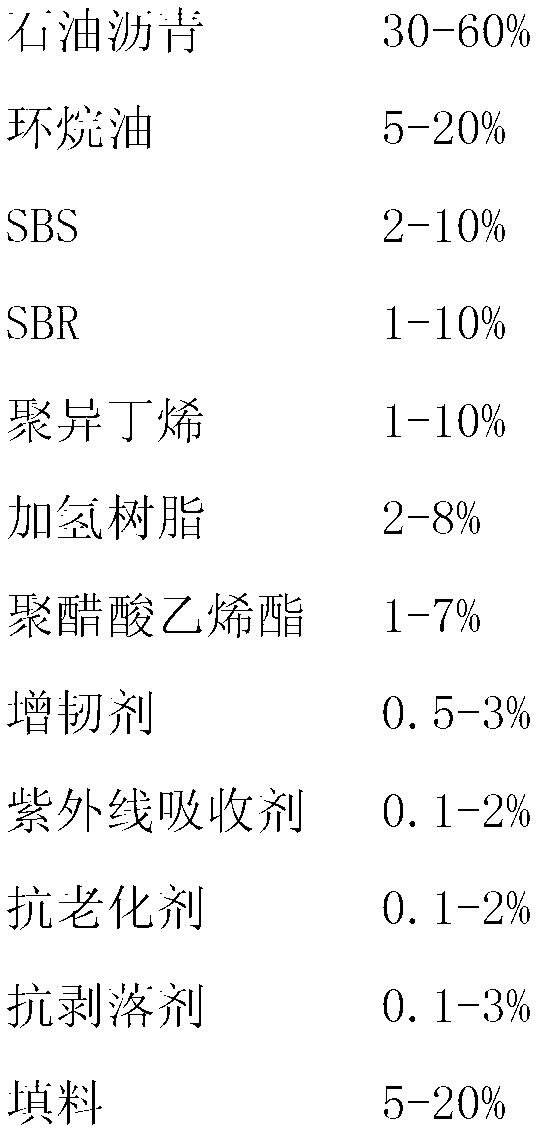

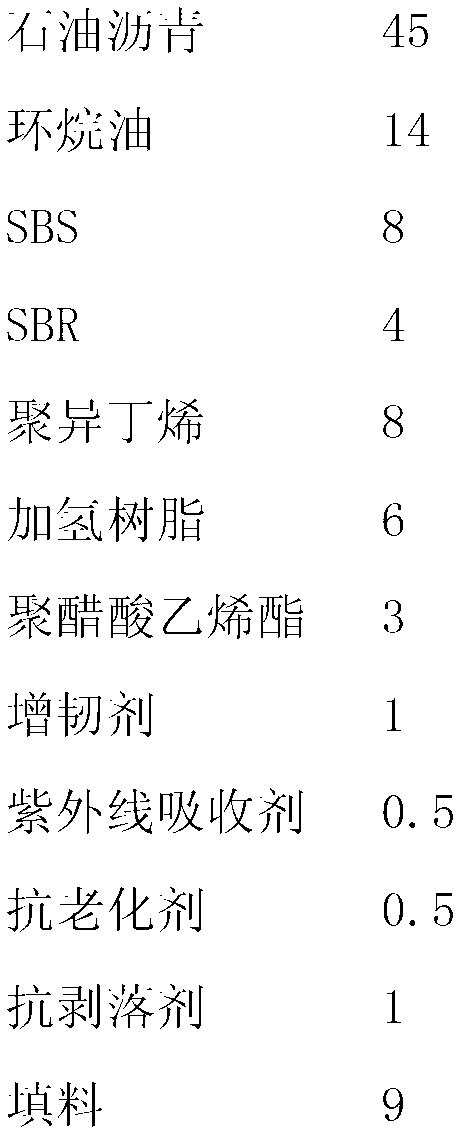

[0056] The typical formula of the modified asphalt self-adhesive film coating is as follows:

[0057] Formula (polyisobutylene molecular weight 2000, polyvinyl acetate polymerization degree 480, toughen...

Embodiment 3

[0062] A product structure similar to Example 1, wherein the film thickness of HDPE (molecular weight 200000) is 0.1mm, the coating thickness of the modified asphalt self-adhesive adhesive film is 1.04mm, the specification of the glass fiber mesh cloth is 40g / m2, and the waterproof membrane The overall length of the HDPE film is 1000mm. One end of the HDPE film is completely covered with the modified asphalt self-adhesive adhesive film coating, and the other end is left with a 30mm exposed strip. The glass fiber mesh cloth traverses the entire modified asphalt self-adhesive adhesive film coating. Its depth is 1.4mm below the surface.

[0063] The glass fiber mesh cloth is low-alkali glass fiber mesh cloth, and the content of metal sodium potassium oxide is not higher than 1.5%.

[0064] The typical formula of the modified asphalt self-adhesive film coating is as follows:

[0065] Formula (polyisobutylene molecular weight 3400, polyvinyl acetate polymerization degree 600, toug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com