A method for manufacturing surface texture of a hockey stick striking plate

A production method and hockey stick technology, which are applied in the field of hockey sticks, can solve the problems of high production cost, complex structure, product scrapping and the like, and achieve the effects of low production cost and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0019] A method for manufacturing a surface texture of a hockey stick striker plate, the method for manufacturing the surface texture is as follows:

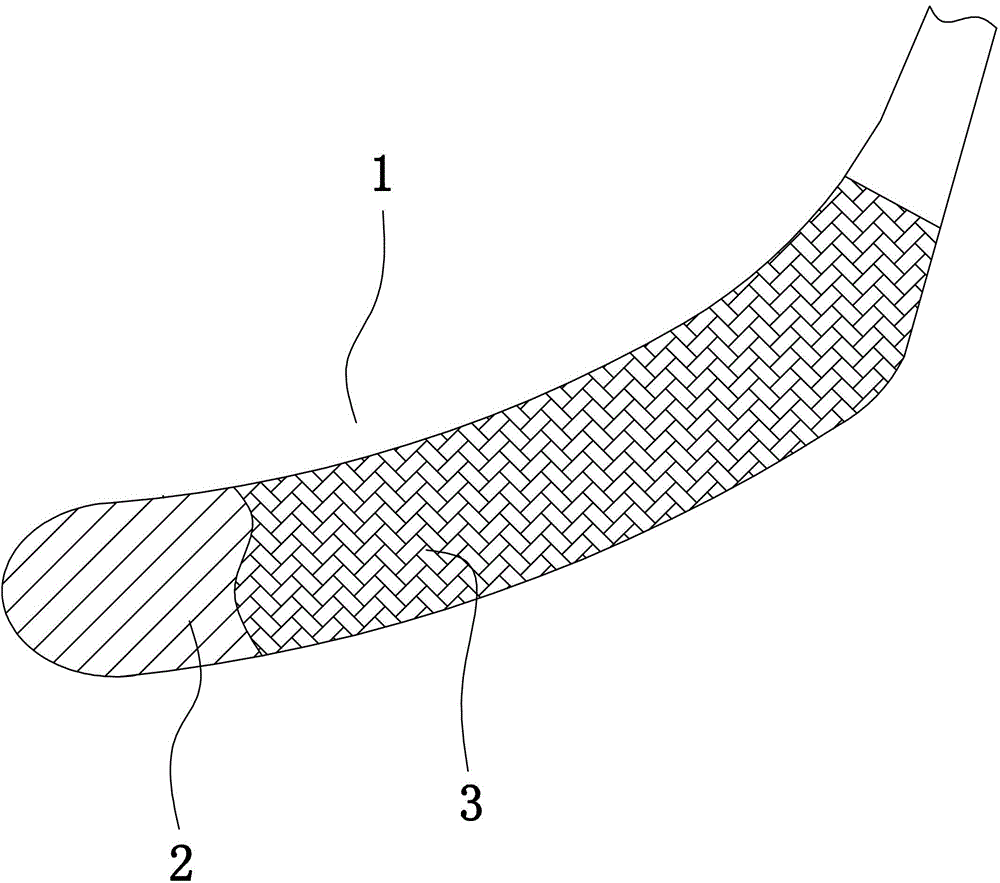

[0020] A: If figure 1 As shown, after the beating board 1 has completed the process of pasting the yarn material 2, the release cloth 3 cut into the outline shape of the beating board is laid flat on the beating board face yarn material 2. The thermal deformation temperature of the base material cloth of the release cloth sheet is greater than 140 degrees. Yarn material 2 is yarn material with resin attached.

[0021] B: Use the heating device to preheat the percussion plate, the preheating temperature is 65±5 degrees, and the preheating time is 1 to 3 minutes; after the percussion plate is preheated, use the pressure plate to press the release cloth on the surface yarn material Or use the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com