Method for preventing fogging when coating a flexible carrier with a crosslinkable liquid silicone composition in a roll device

A technology of roll coating and silicone coating, which is applied to the device and coating of surface coating liquid, which can solve the problems of not providing quantitative factors for evaluation, and achieve the effect of improving hygiene and safety conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0343] 1) Preparation of anti-fogging additive E:

[0344] In the following examples, the following compounds were used.

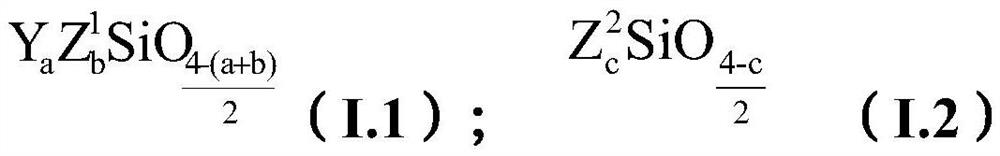

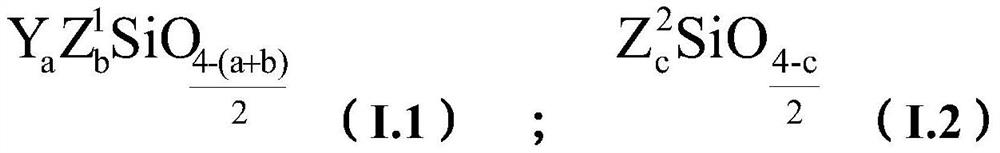

[0345] F1: Organopolysiloxane of the formula with 31 mmol of acrylate functionality per 100 g.

[0346]

[0347] F2: Silmer ACR Supplier Siltech Corporation, which is a dimethylpolysiloxane with two acrylate functional groups at the chain ends, with 50 mmol of acrylate functional groups per 100 grams.

[0348] G1: Organopolysiloxane with the same general formula as F1, with 199 mmol of acrylate functionality per 100 g.

[0349] H1: Hexylene glycol acrylate with 885 mmol of acrylate functionality per 100 grams.

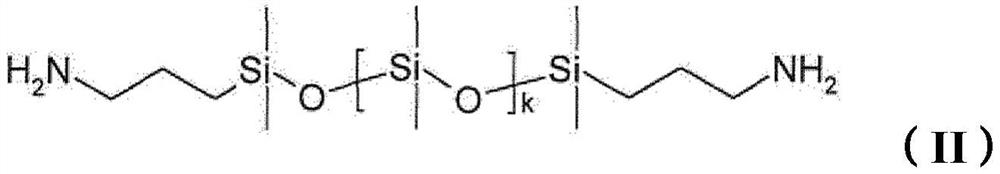

[0350] N1: Organopolysiloxane of the formula, having 43 mmol of amine functionality per 100 g.

[0351]

[0352] isopropyl alcohol

[0353] Synthesis of branched polymers:

[0354] All compounds tested as anti-fogging additives were synthesized by the same method.

[0355] Compounds F, G, H and N were introduced into the flask in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com