Split type diamond specially-shaped grinding wheel and manufacturing technology thereof

A manufacturing process and diamond technology, applied in the manufacture of tools, bonded grinding wheels, metal processing equipment, etc., can solve the problems of difficult processing, poor fluidity of metal powder, waste, etc., and achieve the effect of saving raw materials and reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, technical scheme of the present invention will be further described:

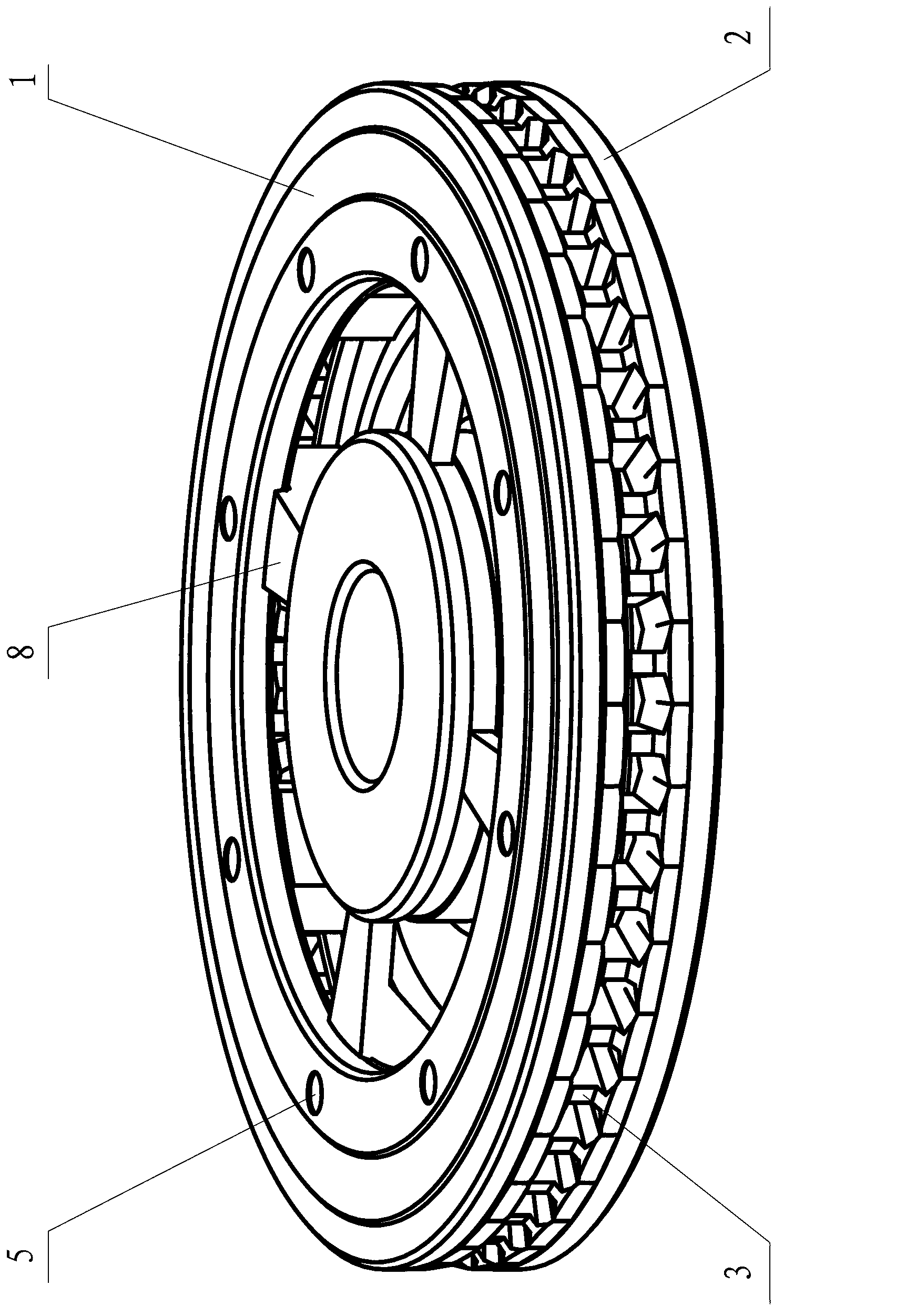

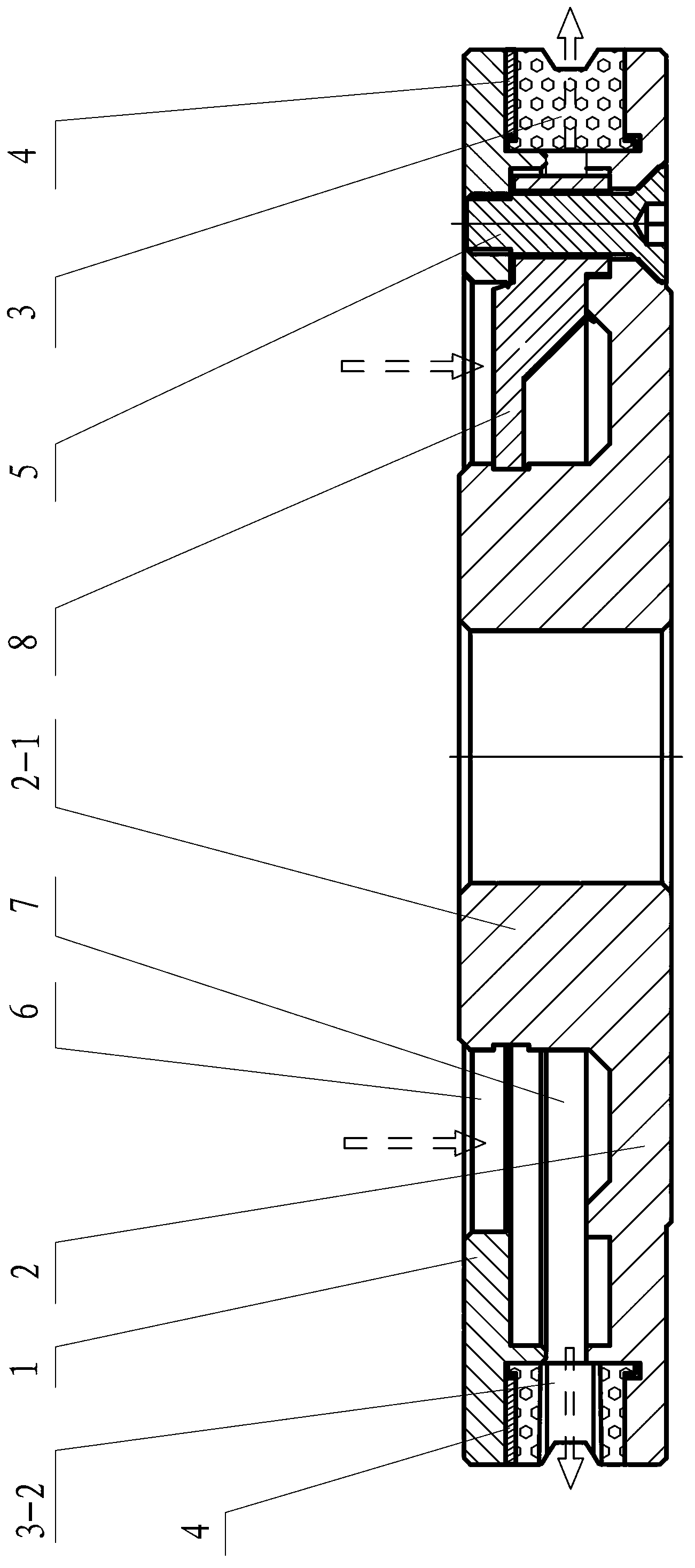

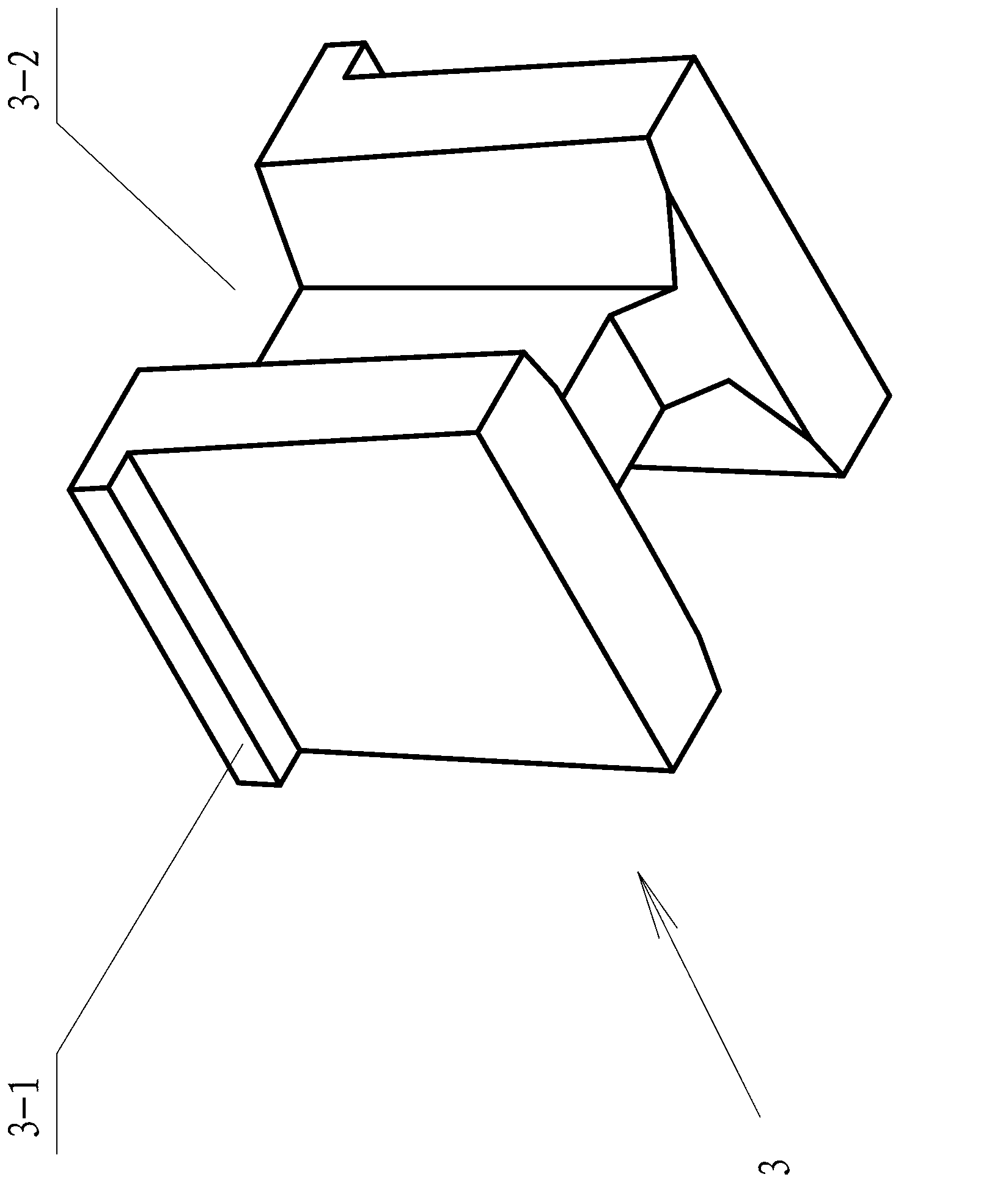

[0030] The split-type diamond special-shaped grinding wheel of the present invention clamps and consolidates grinding rings with isomorphic wear structures into a special-shaped grinding wheel through a base body, wherein the base body is assembled with a pressing plate 1 and a base plate 2, and the grinding ring is composed of several The single teeth 3 are spliced together, the spliced grinding ring is placed on the outer edge of the base plate 2, the annular pressure plate 1 is placed on the support pad 8 evenly distributed on the base plate 2, and the pressure plate 1 is tightened by the fastening screws 5 at the corresponding positions. Fixed on the base plate 2, the outer circumference of the pressure plate 1 clamps and fixes the split grinding ring on the base plate 2, an annular water inlet groove 6 is formed between the pressure plate 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com