Environment-friendly mixed solvent used for pyrethroid pesticide preparation

A pesticide preparation and mixed solvent technology, applied in the fields of application, insecticide, biocide, etc., can solve the problems of unspecified stability index and narrow dissolution range, etc., and achieve improved solubility, good stability, and significant synergistic effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

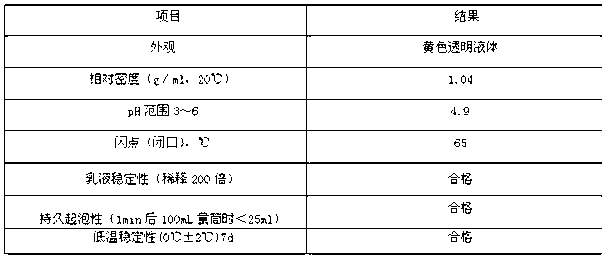

Image

Examples

Embodiment 1

[0039] Solvent sample 1: Weigh 5 kg of dimethyl carbonate and 95 kg of white oil respectively, and then stir evenly to obtain 100 kg of the mixed solvent of this example.

[0040] 3% beta-cypermethrin aqueous emulsion (sample 1)

[0041] The mass percentage of each component in the formula: 95% beta-cypermethrin technical: 3%, solvent sample 1 10%, fatty alcohol polyoxyethylene ether 3%, polycarboxylate 2%, ethylene glycol 3%, defoamer 0.05 %, make up to 100% with water.

[0042] The lambda-cypermethrin in the above example can also be replaced by the formulation products of cypermethrin, lambda-cyhalothrin, deltamethrin, esfenvalerate, cyperethrin and bifenthrin.

[0043] 3% beta-cypermethrin aqueous emulsion (control sample 1)

[0044]The mass percentage of each component in the formula: 95% beta-cypermethrin Technical: 3%, xylene 10%, fatty alcohol polyoxyethylene ether 3%, polycarboxylate 2%, ethylene glycol 3%, defoamer 0.05% , Make up to 100% with water.

[0045] For...

Embodiment 2

[0063] Solvent sample 2: Weigh 20 kg of dimethyl carbonate and 80 kg of white oil respectively, and then stir evenly to obtain 100 kg of the solvent composition of this example.

[0064] 2.5% bifenthrin microemulsion (sample 2)

[0065] The mass percentage of each component in the formula: 95% Bifenthrin Technical: 2.5%, solvent sample 50% (in this product, it is equivalent to adding 10% dimethyl carbonate, white oil 40%), alkyl aryl poly Oxypropylene polyoxyethylene ether 8%, polycarboxylate 7%, calcium dodecylbenzene sulfonate 2%, ethylene glycol 3%, defoamer 0.05%, water to make up to 100%.

[0066] The bifenthrin in the above example can also be replaced by the formulation products of lambda-cypermethrin, cypermethrin, lambda-cyhalothrin, deltamethrin, fenvalerate and fenvalerate.

[0067] 2.5% bifenthrin microemulsion (control sample 2)

[0068] The mass percentage of each component in the formula: 95% Bifenthrin Technical: 2.5%, xylene 40%, methanol 10%, alkylaryl poly...

Embodiment 3

[0087] Solvent sample 3: Weigh 40 kg of dimethyl carbonate and 60 kg of white oil respectively, and then stir evenly to obtain 100 kg of the solvent composition of this example.

[0088] 5% deltamethrin emulsifiable concentrate (sample 3)

[0089] Mass percentage of each component in the formula: 95% deltamethrin Technical: 5%, solvent sample 50% (equivalent to adding dimethyl carbonate 20%, white oil 30% in this product), nonylphenol polyoxygen Vinyl ether 6%, calcium dodecylbenzenesulfonate 4%, methyl oleate make up to 100%.

[0090] The deltamethrin in the above example can also be replaced by the formulation products of lambda-cypermethrin, cypermethrin, lambda-cyhalothrin, fenvalerate, fenvalerate, and bifenthrin.

[0091] 5% deltamethrin emulsifiable concentrate (control sample 3)

[0092] The mass percentage of each component in the formula: 95% deltamethrin Technical: 5%, xylene 50%, nonylphenol polyoxyethylene ether 6%, calcium dodecylbenzenesulfonate 4%, methanol t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com