Anode structure and fabrication process of top emitting oled device

An anode structure and device technology, which is applied in the field of preparation of anode structures of top light-emitting OLED devices, can solve the problems of device disconnection, device failure, and large-scale production yield decline, so as to reduce the probability of short circuit and reduce the hole injection barrier. , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

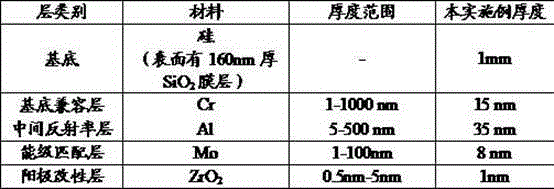

Embodiment 1

[0026] Example 1 : the anode structure of the top emitting OLED device of the present invention, the base thickness is 1mm, made of silicon and SiO 2 Composition, which is characterized by covering the silicon surface with SiO with a thickness of 160nm 2 film. Four-layer thin films were prepared on the substrate in the following manner:

[0027] Step 1: Deposit Cr on the cleaned substrate as a substrate-compatible layer to achieve good compatibility with the substrate; the thickness of the substrate-compatible layer is 15nm, and the film adopts PVD methods such as electron beam evaporation, thermal evaporation, ion beam assisted deposition, and sputtering preparation;

[0028] Step 2: Metal Al with low absorption and high reflection characteristics in the visible light band is deposited on the base compatible layer as an intermediate reflectivity layer with a thickness of 35 nm. The preparation of the intermediate reflectivity layer meets the requirement of high reflectivi...

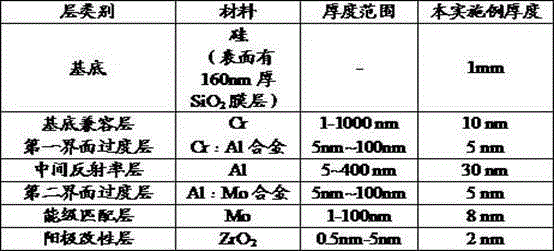

Embodiment 2

[0034] Example 2 : the anode structure of the top emitting OLED device of the present invention, the base thickness is 1mm, made of silicon and SiO 2 Composition, which is characterized by covering the silicon surface with SiO with a thickness of 160nm 2 film. Cover the substrate with four layers of film in the following manner:

[0035] Step 1: Deposit a substrate-compatible layer made of Cr film on the cleaned substrate to achieve good compatibility with the substrate; the thickness of the substrate-compatible layer is 10nm, and the film is prepared by electron beam evaporation;

[0036] The second step: Deposit the first interfacial transition layer on the substrate compatible layer, which is made of Cr and Al alloys. The film is prepared by the PVD method of a multi-source evaporation system, and the ratio is adjusted by controlling the film growth rate between different components. The film thickness is 5nm;

[0037] Step 3: Deposit metal Al with low absorption and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com